Top roller carrying and loading arm

A technology of bearing parts and rollers, applied in the direction of textiles and papermaking, drafting equipment, spinning machines, etc., can solve the problems of high cost, achieve the effects of light weight, shock-absorbing operation, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

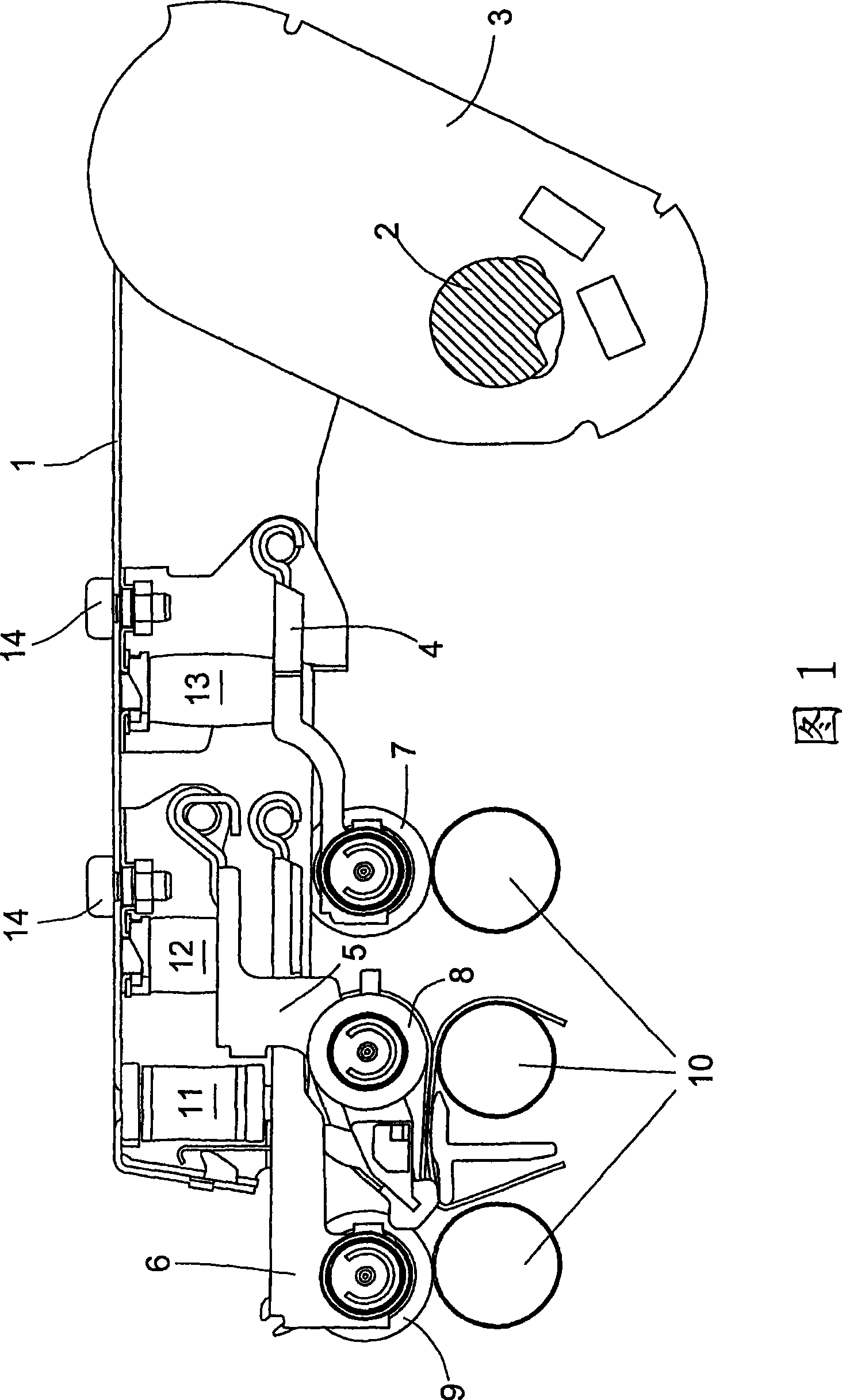

[0021] FIG. 1 shows a partial sectional view of a top roller carrier and a pressure arm 1 of a spinning machine drafting device with adjustable pressure elements for the top rollers 7 , 8 , 9 . The top roller carrier and the pressing arm 1 are pivotally mounted in a support 3 held on a fixed carrier bar 2 and can be actuated by a not shown operating lever. The pressing elements comprise guides 4, 5, 6 of top rollers arranged as a delivery roller 7, an intermediate roller 8 and a feed roller 9, respectively. The top rollers of the drafting device are designed as double rollers and are mounted with their shafts in the receptacles of the guides 4 , 5 , 6 . The guides 4 , 5 , 6 are pressed by resilient elastic compression springs 11 , 12 , 13 in the closed position of the top roller carrier and the pressing arm 1 .

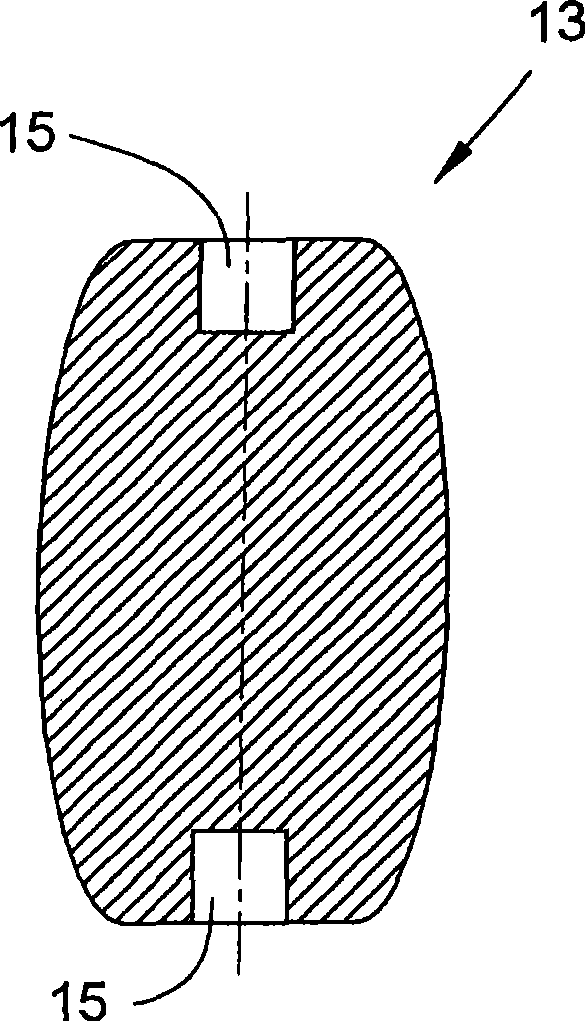

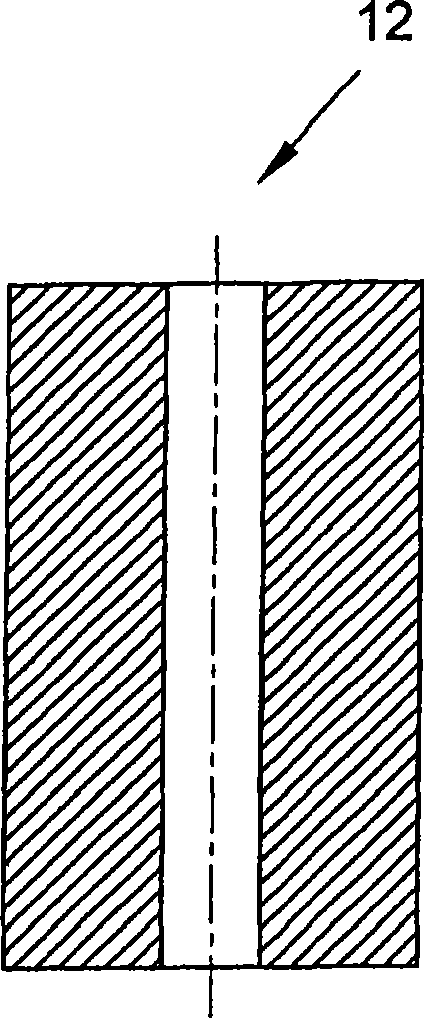

[0022] Compression springs 11, 12, 13 are made of plastic material and are substantially cylindrical. The compression springs 11 , 12 , 13 , which are formed as mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com