Technological equipment for turning spherical inside side surface and spherical outside surface with major diameters mutually matched on common lathe

A process equipment, the technology of ordinary lathes, applied in the field of process equipment for turning large-diameter inter-matching inner and outer spherical surfaces, can solve the problems of low processing efficiency, time-consuming and laborious, complicated production and operation, and achieve the effect of improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

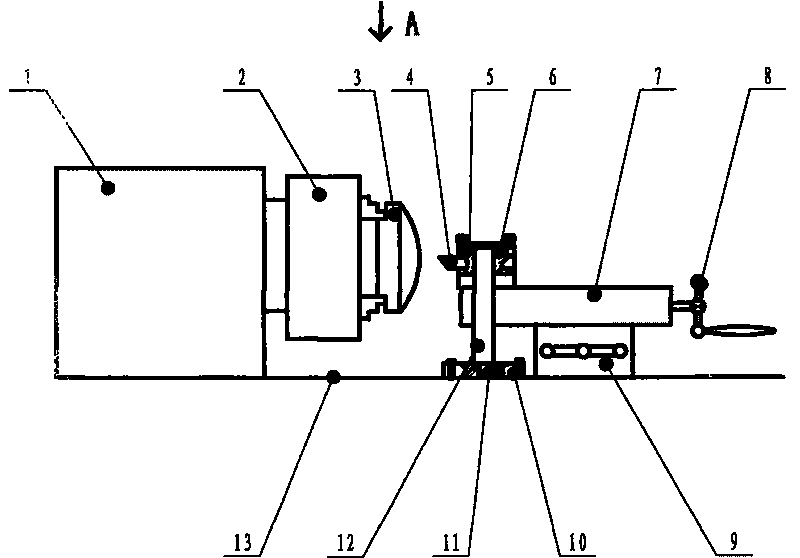

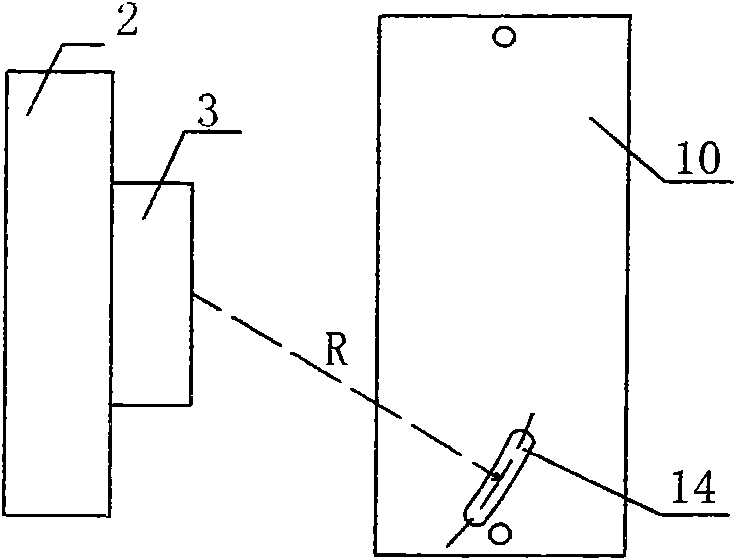

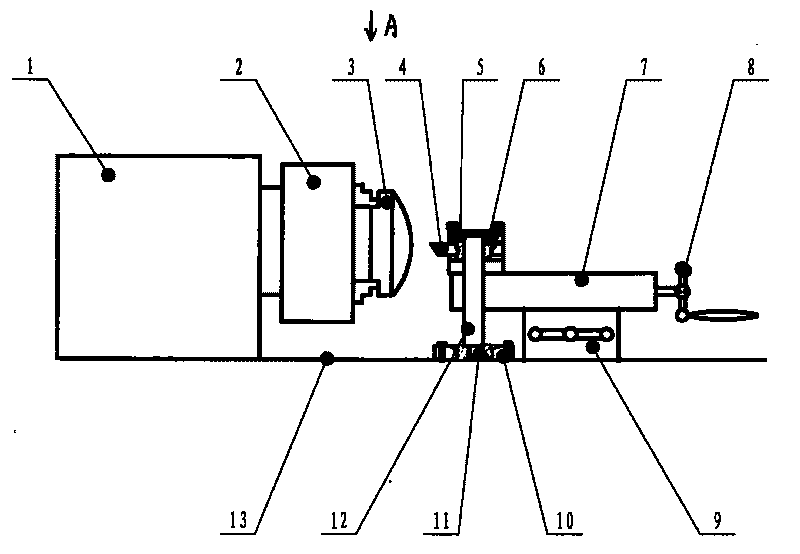

[0012] Such as figure 1 As shown, the present invention comprises guide plate 10 with arc groove, tool holder bar 12 and tool holder 6. Tool holder bar 12 is fixed on the tool holder 6, and tool holder 6 is fixed on the lathe tool rest 5, and the lathe tool holder 5 is fixed on the small carriage 7, and the small carriage 7 is installed on the middle carriage 9. The middle carriage 9 is installed on the guide rail 13 of the lathe bed, and can reciprocate and laterally slide. The small carriage 7 is installed on the middle carriage 9 , pull out the screw rod 8 to make it reciprocate and slide longitudinally. The guide plate 10 with an arc-shaped groove is fixed on the front lathe bed guide rail 13 of the middle carriage, and the lower end of the tool holder rod 12 is inserted in the arc-shaped groove The width of the arc groove is dynamically matched with the outer diameter of the tool seat rod sleeve 11. A copper sleeve can be used for the tool seat rod sleeve 11 to reduce dyn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com