Supporting roller wheel, supporting roller wheel device and transportation device

A technology of transportation device and support roller, which is applied in transportation and packaging, cleaning device, roller column, etc., can solve problems such as affecting the function of transportation rollers and difficult to remove.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

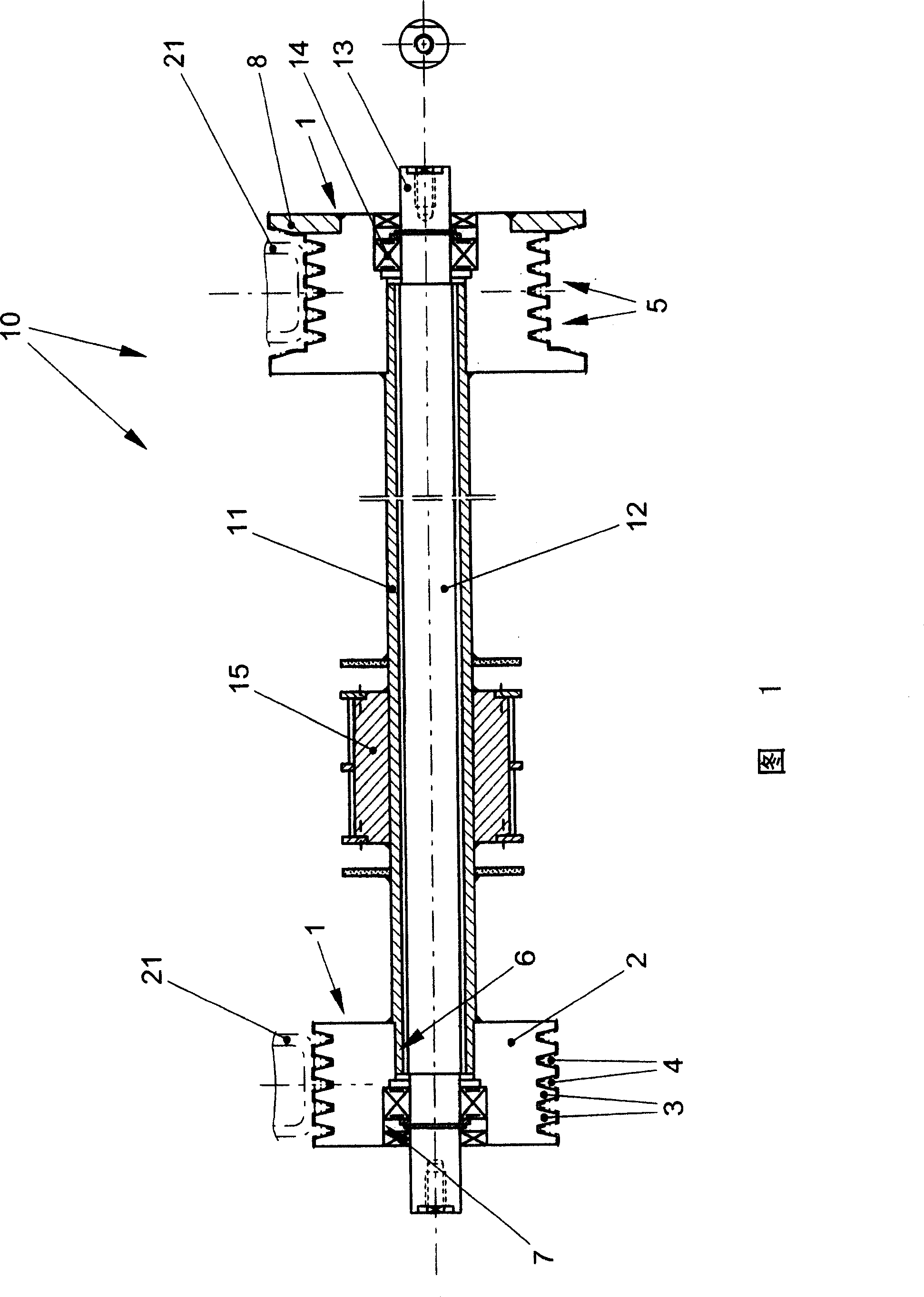

[0052] see first figure 1 .

[0053] A backing roller 1 according to the invention essentially comprises a cylindrical base body 2 with a central bore 6 and a cylindrical outer surface, which is still to be described in more detail.

[0054] The bore 6 can be designed at least partially as a bearing seat 7 , for example for mounting a rolling bearing. The bore 6 can also be designed at least partially as a seat for a spindle and / or shaft.

[0055] According to the invention it is provided that the cylindrical outer surface consists of bearing surfaces 5 extending in the circumferential direction. For this purpose, the cylindrical surface region has surrounding rims 3 and recesses 4 arranged between the rims 3 which separate the rims 3 from one another. Correspondingly, the bearing surface 5 is arranged at the head of the wheel rim 3 , so that the load to be absorbed and transmitted on the backing roller 1 is only supported by the bearing surface 5 , for example in the form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com