High-ultraviolet absorption lignin/chemical sunscreen agent microcapsule and preparation method thereof

一种化学防晒剂、木质素的技术,应用在微胶囊制剂、微球制备、化妆品配制品等方向,能够解决增加制备和分离成本、伤害等问题,达到成本低、制备过程简单、巨大应用前景的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Put 20g of solvent-based lignin in a 500mL beaker, add 180g of aqueous solution of pH 12 to dissolve the lignin, then add dilute hydrochloric acid to adjust the pH of the solution to 8.5, filter out the insoluble matter, and obtain a solvent-based lignin with a mass fraction of 10%. plain water solution.

[0040] (2) 100g of the lignin solution obtained in step (1) and 100g of the chemical sunscreen homosalate were added to the medium, the water-oil ratio was 1:1, and the ultrasonic radiation treatment of 600W power was used for 3min to obtain lignin-containing / Homosalate microcapsule emulsion.

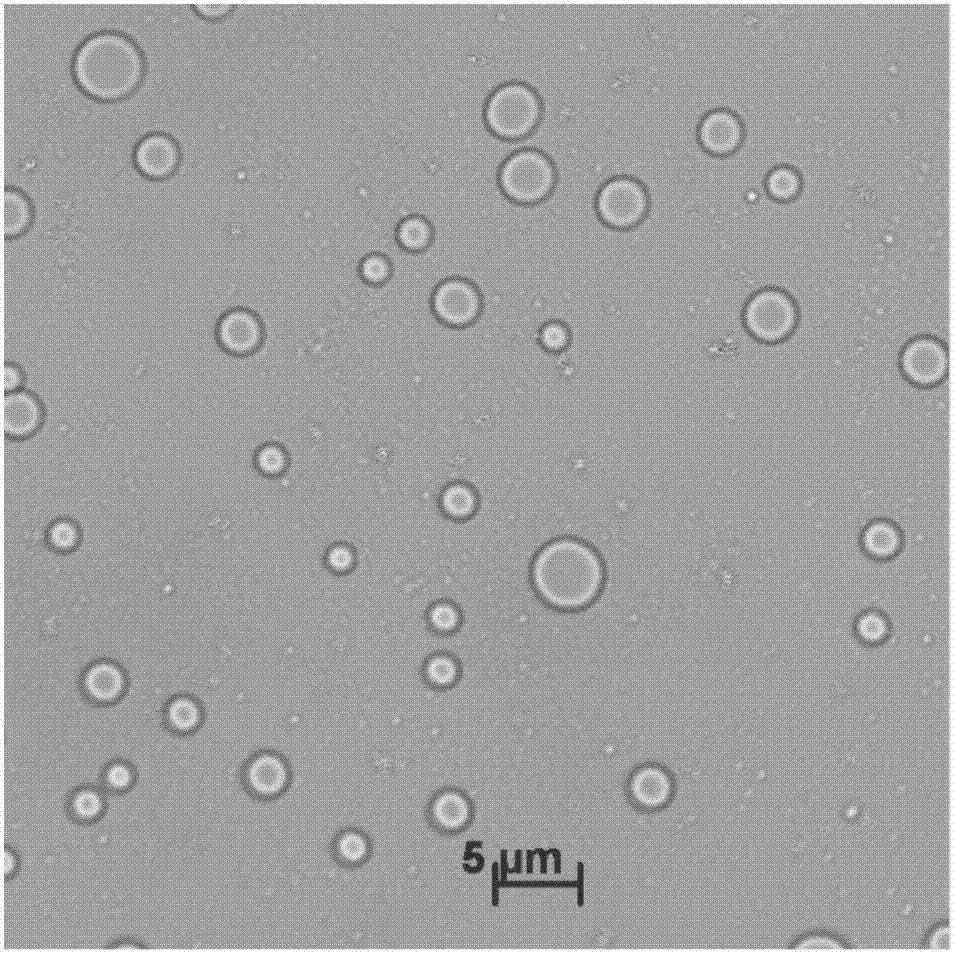

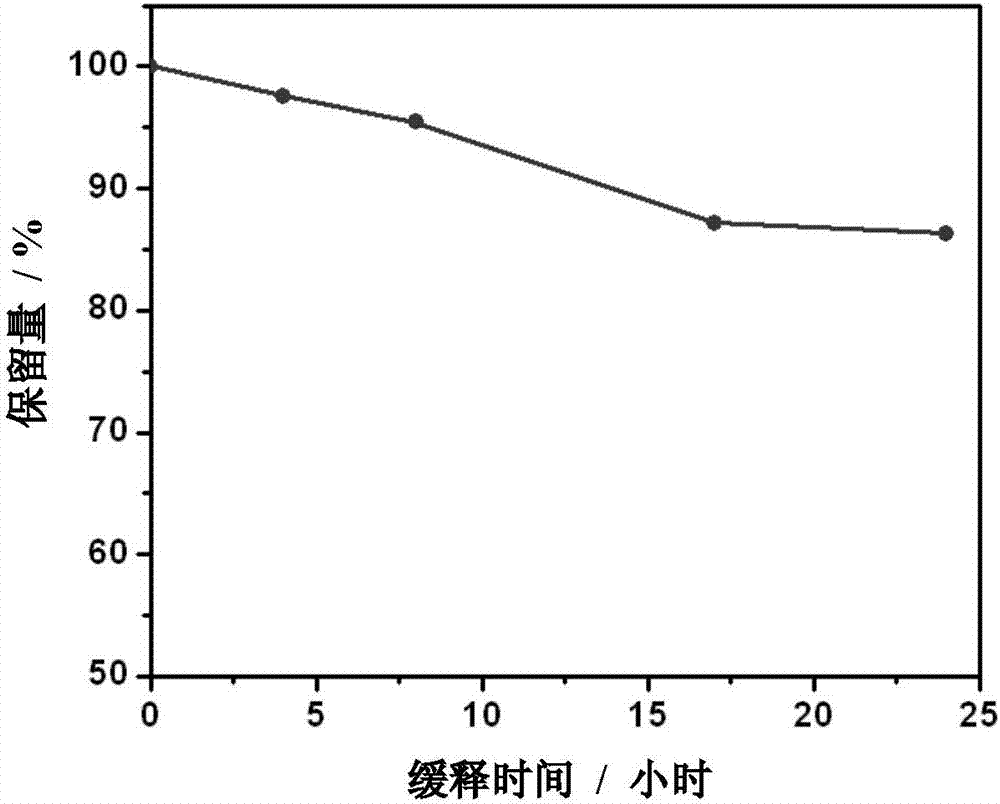

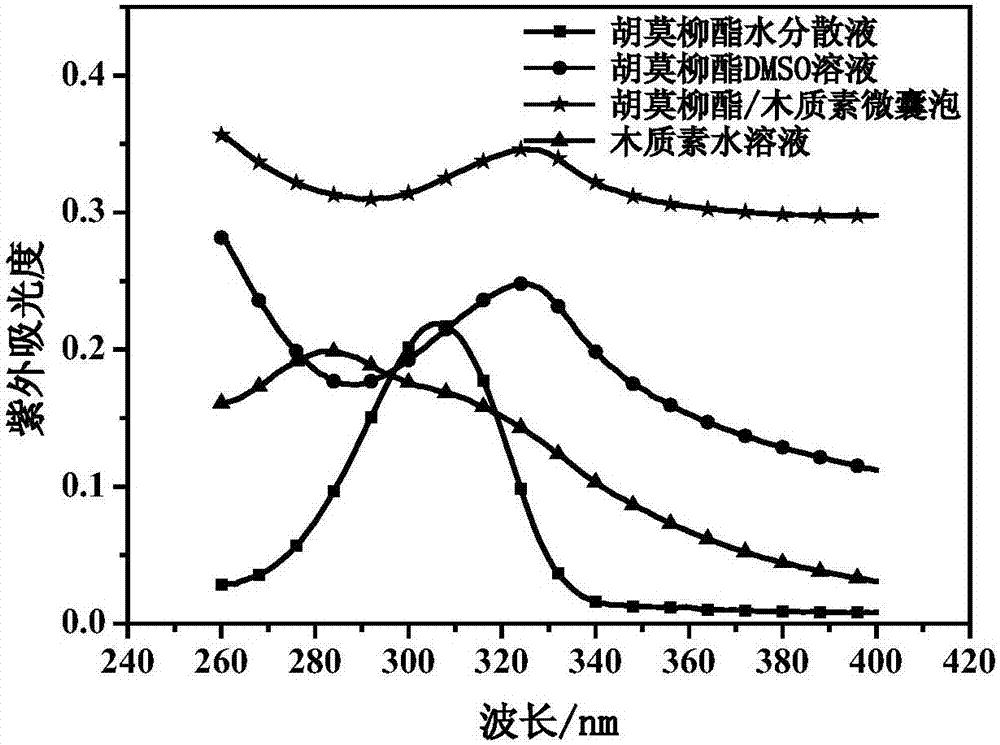

[0041] (3) The emulsion obtained in step (2) was centrifuged and washed for 20 minutes at a speed of 10000 r / min to obtain a lignin / homosalate microcapsule paste. figure 1 It is an optical microscope picture of the lignin / homosalate microcapsules of the product of Example 1 observed by an optical microscope, showing that the microcapsules are spherical structures with a ...

Embodiment 2

[0045] (1) Put 6g of enzymolytic lignin in a 500mL beaker, add 194g of pH12 aqueous solution to dissolve lignin, then add dilute hydrochloric acid to adjust the pH of the solution to 9.5, filter out insolubles, and obtain enzymatic lignin with a mass fraction of 3%. plain water solution.

[0046] (2) 50 g of the lignin solution obtained in step (1) and 5 g of the chemical sunscreen agent isooctyl methoxycinnamate are put into the medium, the water-oil ratio is 10:1, and the ultrasonic radiation of 1000W power is used for 30 seconds, A microcapsule emulsion containing lignin / isooctyl methoxycinnamate was obtained.

[0047] (3) The emulsion obtained in step (2) was centrifuged and washed for 10 min at a speed of 10000 r / min to obtain lignin / isooctyl methoxycinnamate microcapsule paste.

[0048] (4) Adopt optical microscope measurement, slow-release analysis, ultraviolet spectrum measurement identical with embodiment 1, the result is respectively with figure 1 , figure 2 , ...

Embodiment 3

[0050] (1) Put 10g of alkali lignin in a 500mL beaker, add 190g of an aqueous solution of pH 12 to dissolve the lignin, then add dilute hydrochloric acid to adjust the pH of the solution to 9.0, filter out the insoluble matter, and obtain an aqueous solution of alkali lignin with a mass fraction of 5% .

[0051] (2) Add 50 g of the lignin solution obtained in step (1) and 25 g of the chemical sunscreen agent homosalate and avobenzone into the mixture, the water-oil ratio is 2:1, and use 800W power ultrasonic ultrasonic radiation treatment 2min to obtain chemical sunscreen microcapsule emulsion containing lignin / (homosalate and avobenzone).

[0052] (3) The emulsion obtained in step (2) was centrifuged and washed for 10 minutes at a speed of 10000 r / min to obtain a lignin / chemical sunscreen agent microcapsule paste.

[0053] (4) Adopt optical microscope measurement, slow-release analysis, ultraviolet spectrum measurement identical with embodiment 1, the result is respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com