Noniron finishing method for purified cotton textiles with high strength retention

A non-iron finishing and textile technology, applied in textiles and papermaking, fiber processing, plant fibers, etc., can solve the problem of high strength retention, achieve high strength retention, good non-iron and anti-wrinkle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

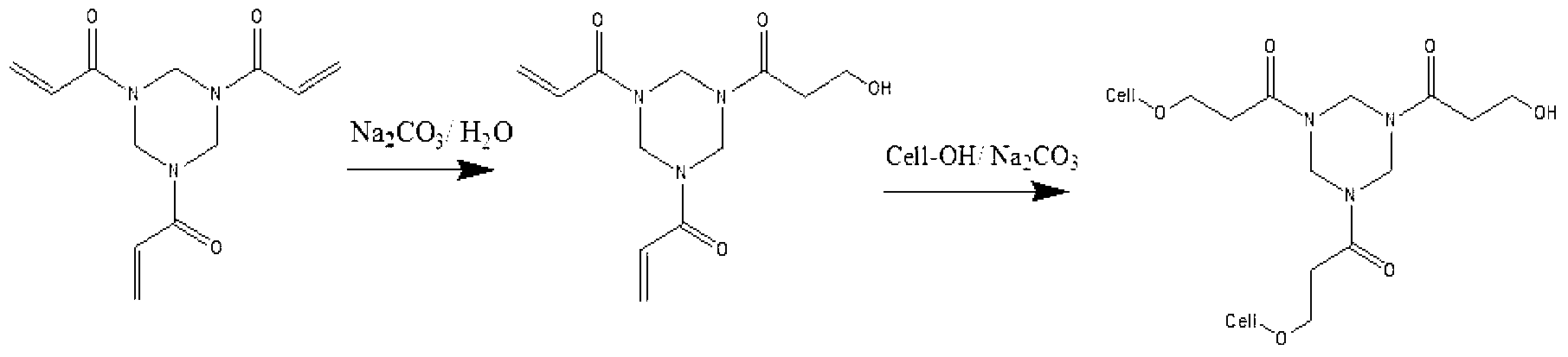

Image

Examples

Embodiment 1

[0017] Add 120g of FAP, 20g of sodium carbonate, and 2g of sodium hydroxide into 1L of water, heat to partially hydrolyze and completely dissolve the FAP, and use it as a finishing solution. Immerse the pure cotton fabric in the finishing solution, soak it completely, dehydrate to 70% of the liquid retention rate, dry at 80°C for 1min, then bake at 140°C for 3min, wash with water, neutralize with HAc, and pad with silicone The softener is then dried at 80°C to obtain the finished product.

Embodiment 2

[0019] Add 100g of FAP and 20g of sodium carbonate into 1L of water, heat to partially hydrolyze and completely dissolve the FAP, and use it as a finishing solution. Padding the pure cotton fabric with the finishing solution, with a liquid retention rate of 60%, steaming it for 2 minutes at 120°C and a humidity of 60%, washing it with water, neutralizing it with HAc, padding it with a silicone softener, and drying it at 80°C to obtain finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com