A kind of colored ultra-high molecular weight polyethylene fiber and its preparation method

A technology of ultra-high molecular weight and polyethylene fiber, which is applied in dyeing, textiles and papermaking, etc., can solve the problems of inability to be applied on a large scale and harsh reaction conditions, and achieve strong repeatability, high retention rate of strength and high appearance effect of depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

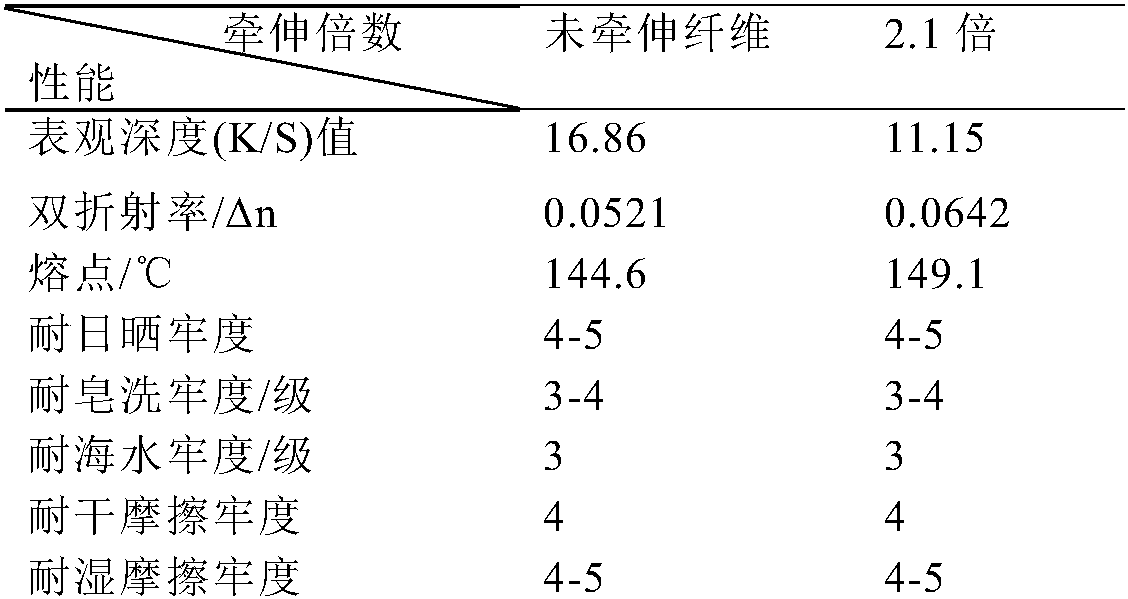

[0027] Embodiment 1 prepares yellow ultrahigh molecular weight polyethylene fiber

[0028] 1. Dyeing step, preparation of yellow ultra-high molecular weight polyethylene extraction fiber

[0029] At room temperature, fatty alcohol polyoxyethylene ether (AEO-9) and dye methyl yellow (Alfa Aisha (China) Chemical Co., Ltd.) were dropped into water by mass ratio of 0.3%, 3% respectively to prepare a dyeing bath. Sonicate the dyeing bath in an ultrasonic cleaning device at 50°C for 30 minutes. After the dyeing solution is evenly dispersed, cool it and let it stand at room temperature for use. Put the dye liquor and the extracted fiber of ultra-high molecular weight polyethylene to be dyed in the cheese dyeing machine at a mass ratio of 100:1, heat up to 100°C at 2°C / min, dye at this temperature for 20 minutes, and then cool down to 80°C. At this temperature, wash in a reducing cleaning solution containing 2g / L sodium hydroxide and 2g / L sodium bisulfite for 20 minutes, and dry in t...

Embodiment 2

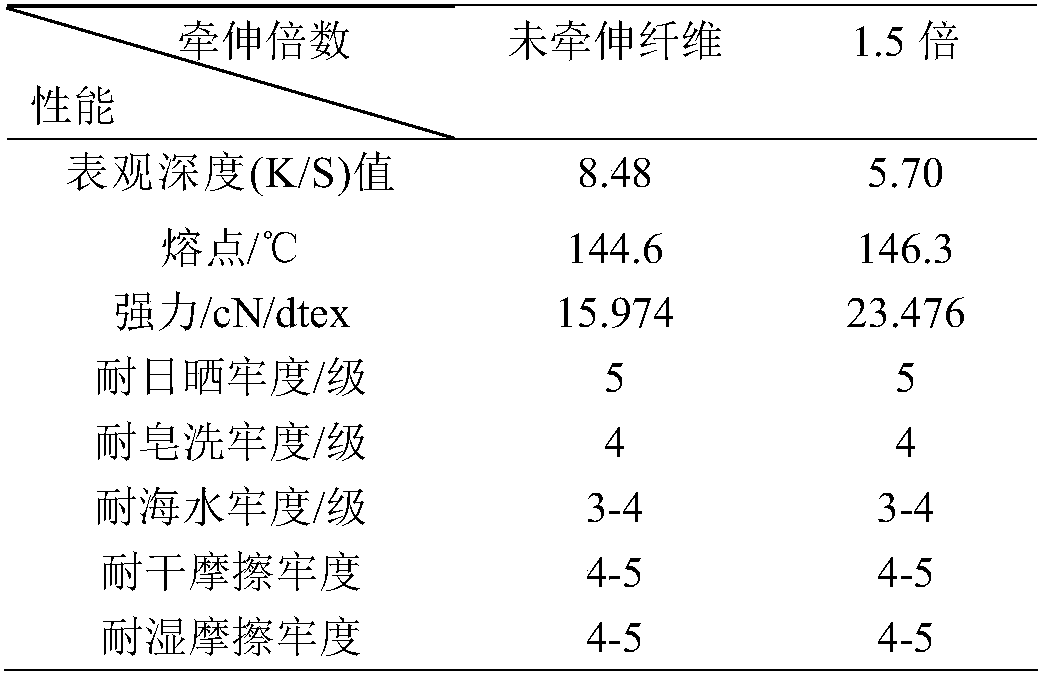

[0034] Embodiment 2 prepares blue ultrahigh molecular weight polyethylene fiber

[0035] 1. Dyeing step, preparation of blue ultra-high molecular weight polyethylene extraction fiber

[0036]At room temperature, fatty alcohol polyoxyethylene ether (AEO-9) and dye Sudan Blue II (Alfa Aisha (China) Chemical Co., Ltd.) were dropped into water by mass ratio of 0.3% and 3% respectively to prepare a dyeing bath. Sonicate the dyeing bath in an ultrasonic cleaning device at 50°C for 30 minutes. After the dyeing solution is evenly dispersed, cool it and let it stand at room temperature for use. Put the dye liquor and ultra-high molecular weight polyethylene extracted fibers in the cheese dyeing machine at a mass ratio of 50:1, raise the temperature to 100°C at 2°C / min, dye at this temperature for 20 minutes, and then cool down to 80°C. Wash for 20 minutes in a reducing cleaning solution containing 2g / L sodium hydroxide and 2g / L sodium bisulfite at low temperature, and dry in the dark ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com