Production process of crease-resistant clothes

A production process and clothing technology, applied in the field of anti-wrinkle of clothes, can solve the problems of high baking temperature and decreased strength of clothes, and achieve the effects of improving anti-wrinkle performance, reducing stiffness and reducing uneven cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The anti-wrinkle clothing production process of the present embodiment comprises the following steps:

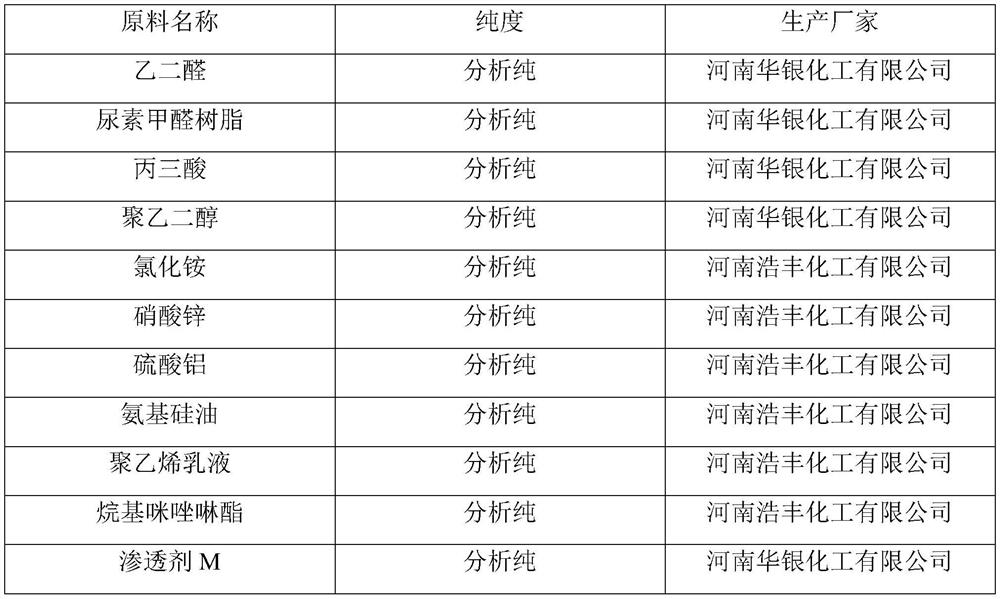

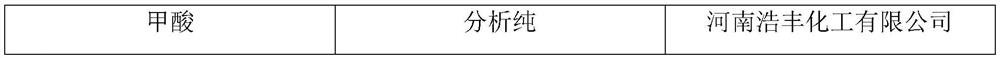

[0044] 1) Preparation of anti-wrinkle finishing solution:

[0045] Mix and stir 100g of finishing agent, 10g of polyethylene glycol, 4g of catalyst and 700g of water at a stirring speed of 150r / min, a stirring temperature of 30°C, and a stirring time of 2h. After mixing evenly, an anti-wrinkle finishing solution is prepared. The catalyst is ammonium chloride, and the finishing agent is glyoxal.

[0046] 2) Anti-wrinkle finishing:

[0047] Soak the clothes to be treated in the anti-wrinkle finishing solution prepared in step 1), and then recirculate, dip, and roll twice after dipping and rolling, wherein, each time dipping and rolling is performed, the rate of rolling is controlled at 75% , then pre-baking the padded clothes, the pre-baking temperature is 60°C, and the pre-baking time is 2min, and then the pre-baking clothes are baked, the baking temperature is 120°C...

Embodiment 2

[0049] The anti-wrinkle treatment process of the present embodiment comprises the following steps:

[0050] 1) Preparation of anti-wrinkle finishing solution:

[0051] 160g of finishing agent, 30g of polyethylene glycol, 18g of catalyst and 800g of water were mixed and stirred, the stirring speed was 150r / min, the stirring temperature was 30°C, the stirring time was 2h, and the anti-wrinkle finishing liquid was obtained after mixing evenly. The catalyst is ammonium chloride, and the finishing agent is glyoxal.

[0052] 2) Anti-wrinkle finishing:

[0053] Soak the clothes to be treated in the anti-wrinkle finishing solution prepared in step 1), and then recirculate, dip, and roll twice after dipping and rolling, wherein, each time dipping and rolling is performed, the rate of rolling is controlled at 75% , followed by pre-baking the padded clothes, the pre-baking temperature is 70°C, and the pre-baking time is 3min, and then the pre-baking clothes are baked, the baking temper...

Embodiment 3

[0055] The anti-wrinkle treatment process of the present embodiment comprises the following steps:

[0056] 1) Preparation of anti-wrinkle finishing solution: Mix 100g of finishing agent, 10g of polyethylene glycol, 4g of catalyst and 700g of water and stir at a stirring speed of 150r / min, at a stirring temperature of 30°C for 2 hours, and add 40g The anti-wrinkle finishing liquid is obtained after stirring and mixing uniformly, the catalyst is ammonium chloride, the finishing agent is glyoxal, and the softening agent is amino silicone oil.

[0057] 2) The anti-wrinkle finishing process is the same as in Example 1.

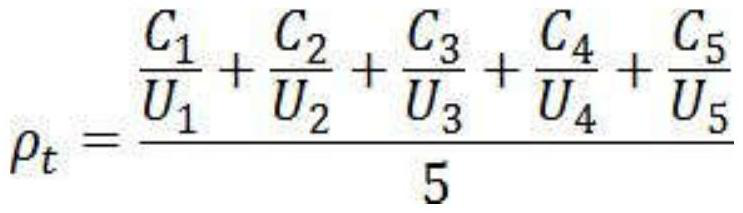

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com