Lasting antibacterial and non-ironingfinishing liquid for cotton fabric and finishing technology

A non-iron finishing and fabric technology, which is applied in the treatment of textile materials, liquid/gas/steam textile material treatment, fiber treatment, etc., can solve the problem of ineffective inhibition of Staphylococcus aureus and Escherichia coli, and long-lasting and effective antibacterial properties , poor wearability of fabrics, etc., to achieve the effect of improving anti-shrinkage and anti-wrinkle effects, improving hand feeling, and excellent antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

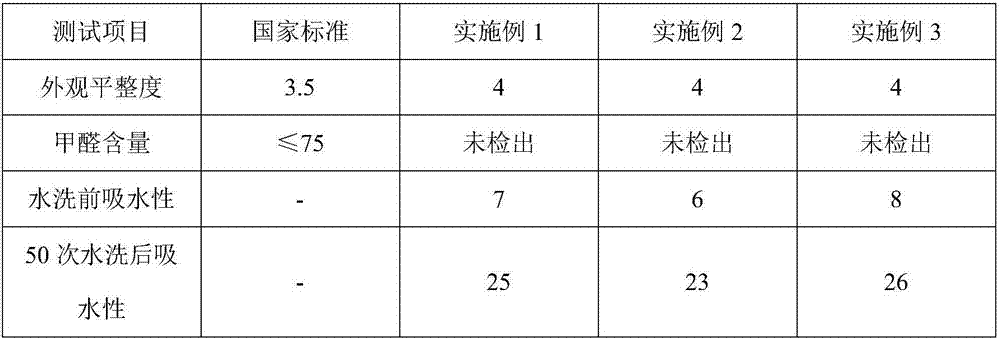

Examples

Embodiment 1

[0019] A long-lasting antibacterial and non-ironing finishing solution for cotton fabrics, comprising the following raw materials in parts by weight: 20 parts of honeysuckle extract, 20 parts of Houttuynia cordata extract, 20 parts of pomegranate peel extract, 2 parts of gum arabic, and 5 parts of nano-zinc oxide 5 parts, 5 parts of nano titanium dioxide, 4 parts of chitosan, 3 parts of silicone softener, 3 parts of carboxymethyl cellulose, 1 part of non-ionic penetrant JFC.

[0020] The honeysuckle extract is prepared by drying and pulverizing honeysuckle and extracting twice with 20% ethanol solution at a solid-to-liquid ratio of 1:10 at a temperature of 60° C. for 1 hour each time. After centrifugation, the extracts are combined and concentrated.

[0021] The Houttuynia cordata extract is obtained by refluxing and extracting Houttuynia cordata cut into sections with 50% ethanol solution at a solid-liquid ratio of 1:10 and a temperature of 50°C for 1 hour each time, centrifug...

Embodiment 2

[0030] A long-lasting antibacterial and non-ironing finishing solution for cotton fabrics, comprising the following raw materials in parts by weight: 30 parts of honeysuckle extract, 30 parts of Houttuynia cordata extract, 30 parts of pomegranate peel extract, 3 parts of gum arabic, and 10 parts of nano zinc oxide 10 parts of nano titanium dioxide, 6 parts of chitosan, 5 parts of ester quaternary ammonium salt, 6 parts of carboxymethyl cellulose, 2 parts of non-ionic penetrant JFC.

[0031] The honeysuckle extract is prepared by drying and pulverizing honeysuckle and extracting twice with 20% ethanol solution at a solid-to-liquid ratio of 1:10 at a temperature of 60° C. for 1 hour each time. After centrifugation, the extracts are combined and concentrated.

[0032] The Houttuynia cordata extract is obtained by refluxing and extracting Houttuynia cordata cut into sections with 50% ethanol solution at a solid-liquid ratio of 1:10 and a temperature of 50°C for 1 hour each time, ce...

Embodiment 3

[0041] A long-lasting antibacterial and non-ironing finishing solution for cotton fabrics, comprising the following raw materials in parts by weight: 25 parts of honeysuckle extract, 25 parts of Houttuynia cordata extract, 25 parts of pomegranate peel extract, 2.5 parts of gum arabic, and 8 parts of nano zinc oxide 8 parts, 8 parts of nano titanium dioxide, 5 parts of chitosan, 4 parts of silicone softener, 5 parts of carboxymethyl cellulose, 1.5 parts of non-ionic penetrant JFC.

[0042] The honeysuckle extract is obtained by drying and pulverizing honeysuckle and extracting twice with 20% ethanol solution at a solid-to-liquid ratio of 1:10 and at a temperature of 60°C under reflux for 1 hour each time. After centrifugation, the extracts are combined and concentrated.

[0043]The Houttuynia cordata extract is obtained by refluxing and extracting Houttuynia cordata cut into sections with 50% ethanol solution at a solid-liquid ratio of 1:10 and a temperature of 50°C for 1 hour e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com