Treatment method for antibacterial and anti-ultraviolet cotton fabrics

A treatment method and cotton fabric technology, applied in fiber treatment, biochemical fiber treatment, plant fiber, etc., can solve the problem of cotton fabric’s unsatisfactory anti-ultraviolet performance, improve anti-oxidation and scavenging free radical performance, improve adsorption fastness, The effect of increasing the amount of binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

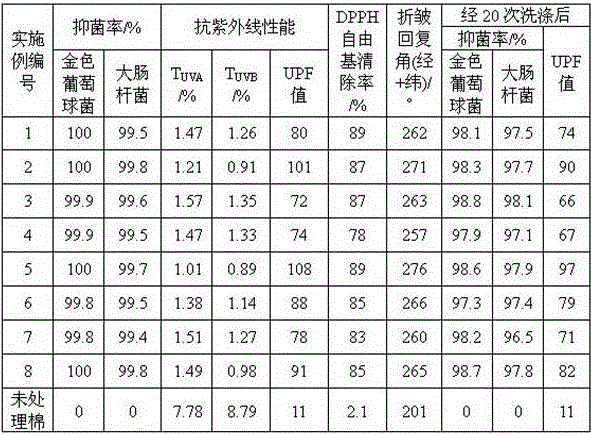

Examples

Embodiment 1

[0038] A natural antibacterial agent preparation:

[0039] Wash the natural plant material grape seeds, dry them, pulverize them with a pulverizer, and extract them under reflux at 70°C for 100 min at 70°C, then vacuum filter 1. Removing slag, concentrating the extract under reduced pressure, and freeze-drying the concentrate to obtain natural antibacterial agent powder.

[0040] B. Pretreatment of cotton fabric: Soak the cotton fabric with an aqueous solution of 0.5 g / L non-ionic surfactant penetrating agent JFC for 5 minutes, take it out, and dry it in the air.

[0041] C carries out chitosan quaternary ammonium salt modification treatment to cotton fabric: with the modified working solution that chitosan quaternary ammonium salt 5 g / L, zinc acetate 1.5 g / L are formed, carry out two treatments to the cotton fabric after step B treatment Soak and roll twice, the excess rate is 120%, dry at 85°C, and then bake at 120°C for 2 minutes.

[0042] D antibacterial finishing liquid...

Embodiment 2

[0050] A natural antibacterial agent preparation:

[0051] Wash the natural plant material persimmon leaves, dry them, pulverize them with a pulverizer, and extract them under reflux at 80°C for 80 minutes according to the weight ratio of the plant material persimmon leaves and 50% ethanol solution with a mass percentage ratio of 1:25, and then vacuum filter 1. Removing slag, concentrating the extract under reduced pressure, and freeze-drying the concentrate to obtain natural antibacterial agent powder.

[0052] B. Pretreatment of cotton fabrics: Soak cotton fabrics in an aqueous solution of 0.4 g / L of non-ionic surfactant Pingping plus O for 6 minutes, take them out, and dry them in the air.

[0053] C carries out chitosan quaternary ammonium salt modification treatment to cotton fabric: with the modified working solution that chitosan quaternary ammonium salt 4 g / L, zinc acetate 3 g / L are formed, carry out two treatments to the cotton fabric after step B treatment Soak and ...

Embodiment 3

[0062] A natural antibacterial agent preparation:

[0063] Wash the natural plant material Ginkgo biloba leaves, dry them in the air, pulverize them with a pulverizer, and extract them under reflux at 65°C for 120 minutes according to the weight ratio of the plant material Ginkgo biloba leaves to the mass percentage of 70% ethanol solution, and then vacuum filter 1. Removing slag, concentrating the extract under reduced pressure, and freeze-drying the concentrate to obtain natural antibacterial agent powder.

[0064] B. Pretreatment of cotton fabric: Soak the cotton fabric in an aqueous solution of 0.3 g / L of nonionic surfactant lauryl glucoside for 8 minutes, take it out, and dry it in the air.

[0065] C. Carry out chitosan quaternary ammonium salt modification treatment to cotton fabric: use the modified working liquid that chitosan quaternary ammonium salt 8g / L, zinc acetate 2 g / L forms, carry out two immersions to the cotton fabric after step B treatment Two rolling, 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com