Novel linear amino and polyester modified organosilicon compound for textiles

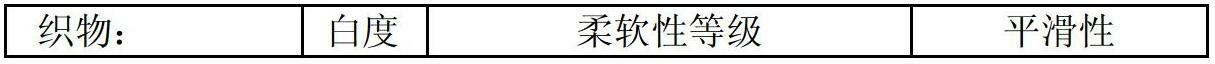

An organosilicon compound and textile technology, applied in textiles and papermaking, plant fibers, fiber processing, etc., can solve the problems of sticking rollers, oil drifting, and excessive hand feeling, and achieve the effect of expanding the use place, convenient use and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] Step 1, D4 reacts with hydrogen-containing silicone oil, using sulfuric acid as a catalyst, sequentially add 900g D4 and 2~10g concentrated sulfuric acid, stir, heat up to 40°C, add hydrogen-containing silicone oil with a mass percentage of 1.8~1.92% 20 ~40g, reacted at 20~80°C for 2~10 hours, added 2~10g of soda ash, stirred for 2 hours, and stood still for 12 hours to obtain intermediate 1

[0038] Step 2: Add 1000g of intermediate to 20~40g of allyl glycidyl ether for reaction, stir and heat to 60~80°C, then add 20~40g of chloroplatinic acid and isopropanol solution (1:1) dropwise to react 2~ After 10 hours, the intermediate product 2 was obtained by this method, and the small molecular products were removed by vacuuming.

[0039] Step 3, add intermediate 1000g (2)

[0040] 5~10g of NH 2 (CH 2 CH 2 O) a wxya 2 and

[0041] 5~10gNH 2 R2(CH 2 (CH 3 ) CHO) c (CH2CHO) d R 3 NH 2 Stir the reaction for 3~5 hours, the viscosity increases, add 200~400g of butyl...

Embodiment 2

[0062] Step 1, D4 reacts with hydrogen-containing silicone oil, using sulfuric acid as a catalyst, sequentially add 900g of D4 and 2g of concentrated sulfuric acid, stir, heat up to 40°C, add 20g of high hydrogen-containing silicone oil with a mass percentage of hydrogen of 1.92%, at 20~ React at 80°C for 2 to 10 hours, add soda ash and stir for 2 hours, then stand still for 12 hours to obtain intermediate 1

[0063] Step 2: Add 1000g of intermediate to 30g of allyl glycidyl ether for reaction, stir and heat to 60~80°C, then dropwise add chloroplatinic acid and isopropanol solution to react for 2~10 hours, this method obtains intermediate product 2 , to remove small molecule products (i.e., impurities) by vacuuming.

[0064] Step 3, add intermediate 1000g (2)

[0065] 10 g NH 2 (CH 2 CH 2 O) a wxya 2 and

[0066] 10 g NH 2 R2(CH 2 (CH 3 ) CHO) c (CH2CHO) d R 3 NH 2 Stir the reaction for 3~5 hours, control the appropriate viscosity, the viscosity increases, add 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com