High whiteness textile non-ironing finishing method and textile

A non-iron finishing and textile technology, applied in textiles and papermaking, plant fibers, fiber processing, etc., can solve the problems of insufficient whiteness, translucency, low whiteness improvement, and low whiteness, etc. White and no-iron effect, optimized processing effect, high-quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

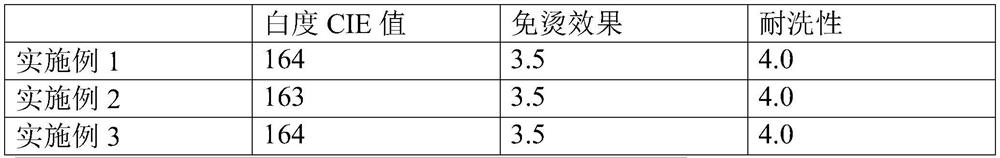

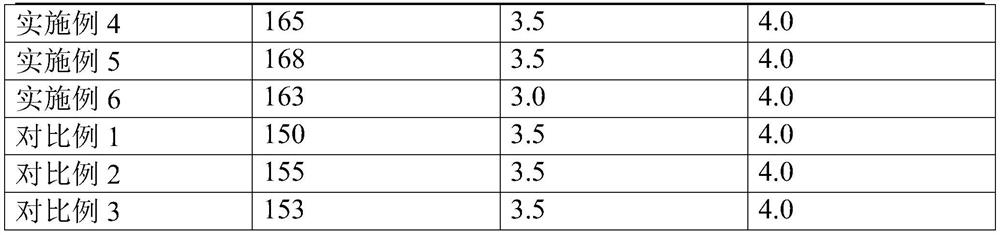

Examples

Embodiment 1

[0031] This embodiment is a high-whiteness non-ironing finishing method for textiles. The textiles to be finished are pure cotton white woven fabrics, and the single yarn count is 50S. The non-ironing finishing steps are as follows:

[0032] (1) Pre-treatment: Singeing and desizing the textiles to be finished according to conventional methods;

[0033] (2) High-alkali concentrated mercerizing: use a sodium hydroxide aqueous solution with a concentration of 24 mg to carry out mercerizing, and the processing time is about 60s;

[0034] (3) Liquid ammonia mercerizing: use Koyto liquid ammonia mercerizing machine, the speed is 60 m / min, and the corresponding soaking time in liquid ammonia is about 20s;

[0035] (4) Cold stacking and whitening: dipping the textiles after liquid ammonia mercerizing with the treatment liquid, then stacking for 15 hours, and drying with a setting machine; the treatment liquid is fluorescent whitening agent BMU (stilbene two Derivatives of sulfonic ac...

Embodiment 2

[0039] In this embodiment, a high-whiteness non-ironing finishing method for textiles, the textiles to be finished and the steps are the same as in Example 1, the difference is that:

[0040] In step (4), the time of stacking is 22 hours.

Embodiment 3

[0042] In this embodiment, a high-whiteness non-ironing finishing method for textiles, the textiles to be finished and the steps are the same as in Example 1, the difference is that:

[0043] In step (5), the moisture content of the textile after the moisture crosslinking treatment is controlled to 6-8%, and the stacking time is 25 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com