Method for preparing non-ironing multifunctional blended yarn by utilizing electrostatic spinning nanotechnology

A technology of electrospinning and nanotechnology, applied in the direction of electrospinning, rayon manufacturing, yarn, etc., can solve the problems that ordinary fiber materials do not have functionality, limit personalized consumption, etc., and achieve increased specific surface area and improved The effect of filter performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] A method for preparing non-iron multifunctional blended yarns using electrospinning nanotechnology, using the cotton-type carding process route: raw materials→cotton blending→opening and cleaning→carding→drawing (1)+electrospinning→paralleling Strip (2)→roving→spinning→sizing→weaving→finishing

[0065] 1. Raw material ratio

[0066] Long-staple cotton 80%;

[0067] Electrospun micro-nano fibers 20%.

[0068] 2. Opening and cleaning process

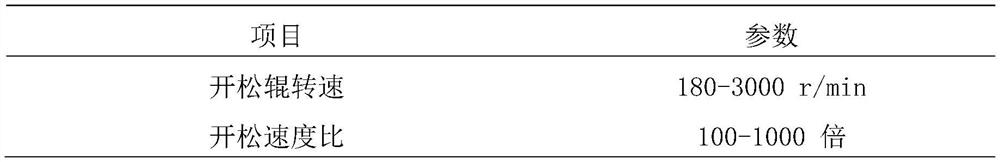

[0069] The process parameters of opening and cleaning are: temperature 25°C, relative humidity 55%, opening roller speed 180r / min, opening speed ratio 100 times.

[0070] 3. Carding process

[0071] The carding process parameters are: temperature 25°C, relative humidity 55%, cylinder rotation speed 100r / min, surface line speed ratio (cylinder / licker-in roller): 2 times, web outlet speed 0.5m / min, total draft speed ( Doffer / feeding cotton) 10 times.

[0072] 4. Drawing process

[0073] Keep the temperature at 25°C and the rela...

Embodiment 2

[0087] A method for preparing non-iron multifunctional blended yarns using electrospinning nanotechnology, using the cotton-type carding process route: raw materials→cotton blending→opening and cleaning→carding→drawing (1)+electrospinning→paralleling Strip (2)→roving→spinning→sizing→weaving→finishing

[0088] 1. Raw material ratio

[0089] Long-staple cotton 99%;

[0090] Electrospun micro-nano fibers 1%.

[0091] 2. Opening and cleaning process

[0092] The process parameters of opening and cleaning are: temperature 26°C, relative humidity 65%, speed of opening roller 3000r / min, opening speed ratio 1000 times.

[0093] 3. Carding process

[0094] Carding process parameters are: temperature 26°C, relative humidity 65%, cylinder speed 2500r / min, surface line speed ratio (cylinder / licker-in roller): 12 times, web outlet speed 50m / min, total draft speed (doffer / to cotton) 200 times.

[0095] 4. Drawing process

[0096]Keep the temperature at 26°C and the relative humidit...

Embodiment 3

[0111] A method for preparing non-iron multifunctional blended yarns using electrospinning nanotechnology, using the cotton-type carding process route: raw materials→cotton blending→opening and cleaning→carding→drawing (1)+electrospinning→paralleling Strip (2)→roving→spinning→sizing→weaving→finishing

[0112] 1. Raw material ratio

[0113] Long-staple cotton 90%;

[0114] Electrospun micro-nano fibers 10%.

[0115] 2. Opening and cleaning process

[0116] The process parameters of opening and cleaning are: temperature 25°C, relative humidity 60%, speed of opening roller 1500r / min, opening speed ratio 500 times.

[0117] 3. Carding process

[0118] Carding process parameters are: temperature 25°C, relative humidity 60%, cylinder rotation speed 1300r / min, surface line speed ratio (cylinder / licker-in roller): 7 times, web outlet speed 25m / min, total draft speed (doffer / to cotton) 100 times.

[0119] 4. Drawing process

[0120] Keep the temperature at 25°C and the relativ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com