Non-ironing crease-proofing agent and preparation thereof

A technology of anti-wrinkle finishing agent and catalyst, which is applied in fiber treatment, textiles and papermaking, etc. It can solve the problems of non-ironing effect and unsatisfactory fastness of fabrics, achieve good catalytic effect, reduce glass transition temperature, and improve film formation sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

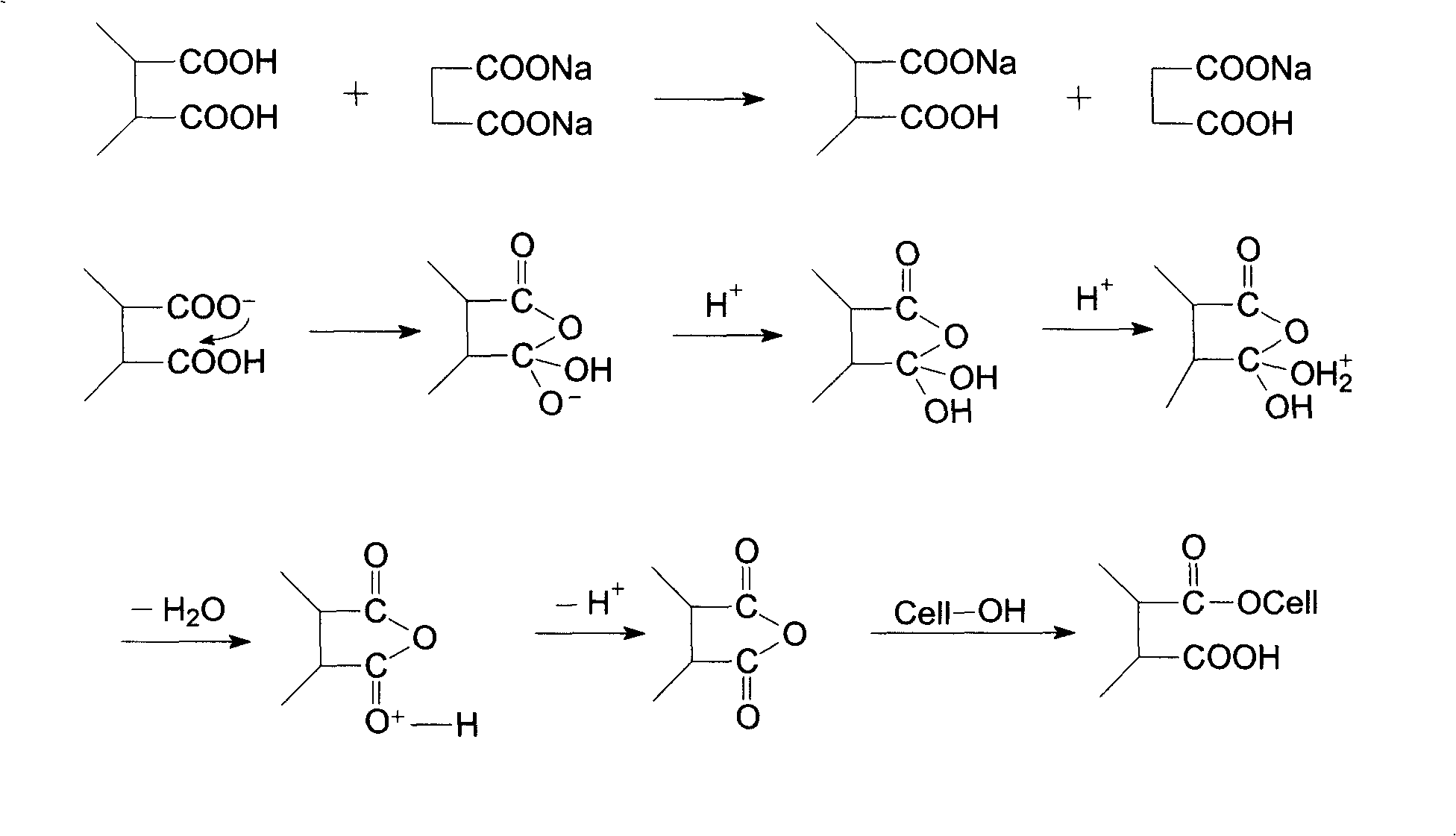

Method used

Image

Examples

Embodiment 1

[0021] Add 81.2 grams of maleic acid, 80.0 grams of acrylic acid, 40.0 grams of ethyl acrylate and 300 grams of deionized water into a 1-liter four-necked bottle, and stir to mix evenly. Use a constant temperature water bath to control the temperature of the material at about 70° C., protect it with nitrogen gas, and slowly add 30 g of a 30% mass concentration of ammonium persulfate aqueous solution dropwise under stirring. After the initiator is added dropwise within 1.5h, continue stirring at constant temperature for 0.5h to end the reaction and obtain a light yellow translucent solution. Add 10.1 grams of ethanolamine and 2.0 grams of sodium citrate, and add an appropriate amount of deionized water to adjust the mass concentration of the system. to 30%.

Embodiment 2

[0023] Add 60.6 grams of maleic acid, 52.3 grams of itaconic acid, 42.5 grams of ethyl methacrylate and 300 grams of deionized water into a 1-liter four-necked bottle, and stir to mix evenly. Use a constant temperature water bath to control the temperature of the material at about 75° C., protect it with nitrogen, and slowly add 35 g of a 30% mass concentration of ammonium persulfate aqueous solution dropwise under stirring. After the initiator is added dropwise within 2 hours, continue stirring at constant temperature for 1 hour to end the reaction and obtain a light yellow translucent solution. Add 9.0 grams of diethanolamine and 2.3 grams of disodium citrate, and add an appropriate amount of deionized water to adjust the mass concentration of the system. to 30%.

Embodiment 3

[0025] Add 46.4 grams of maleic acid, 104.4 grams of itaconic acid, 7.2 grams of acrylic acid, 25.6 grams of butyl acrylate and 350 grams of deionized water into a 1-liter four-necked bottle, and stir and mix evenly. A constant temperature water bath is used to control the temperature of the material at about 80° C., and under nitrogen protection, 40 g of a 30% mass concentration AIBA aqueous solution is slowly added dropwise under stirring. After the initiator is added dropwise within 2.5 hours, continue to stir at a constant temperature for 0.5 hours to end the reaction and obtain a light yellow translucent solution. Add 11.4 grams of triethanolamine and 3.7 grams of trisodium citrate, and add an appropriate amount of deionized water to reduce the quality of the system. Adjust the concentration to 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com