Non-ironing crease-proofing agent and use method thereof

A technology of anti-wrinkle finishing agent and catalyst, which is applied in fiber treatment, textiles and papermaking, plant fiber, etc. It can solve the problems of unsatisfactory non-ironing effect of fabrics, achieve low cost, improve crosslinking effect, and high flatness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

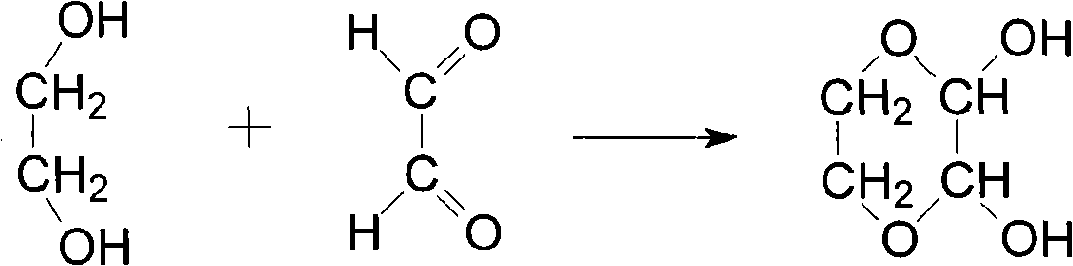

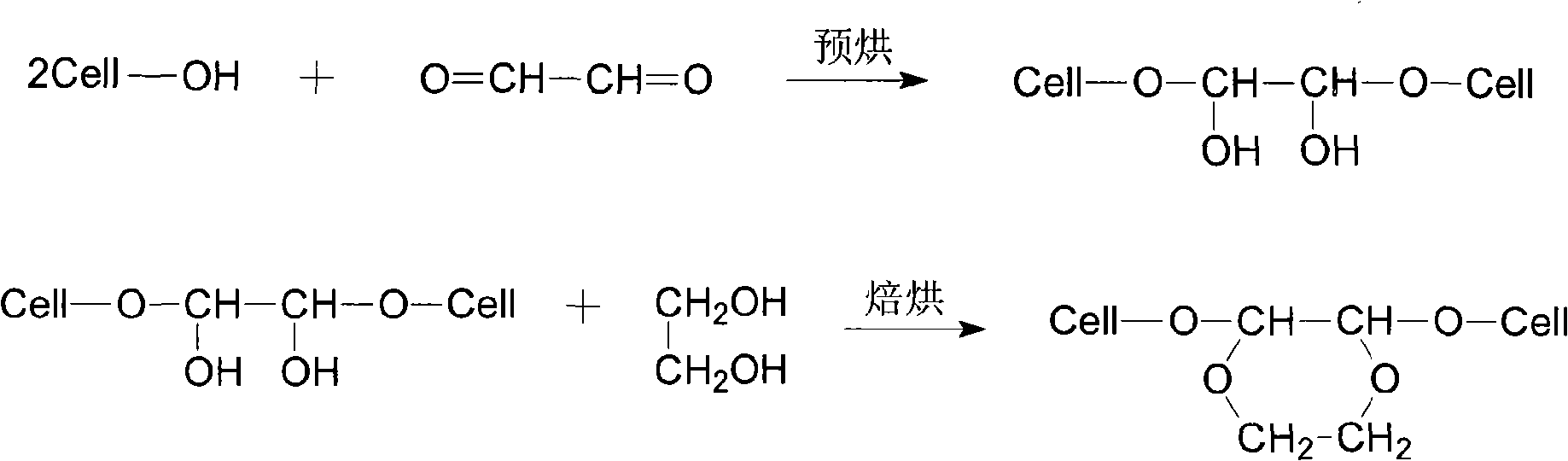

Method used

Image

Examples

Embodiment 1

[0025] 100 parts of glyoxal (40%), 70 parts of aluminum sulfate, 10 parts of aluminum citrate, 400 parts of ethylene glycol, and 300 parts of deionized water are used to control the temperature of the material at 30°C with a constant temperature water bath, and stir for 0.5h. A light yellow translucent solution was obtained, and an appropriate amount of deionized water was added to adjust the mass concentration of the product system to 30%. Sodium perborate is 0.1% (to the working fluid wt%), and formic acid is 1.0% (to the working fluid wt%), and the two are directly added to the rolling groove working fluid when the fabric is processed.

Embodiment 2

[0027] 110 parts of glyoxal (40%), 100 parts of aluminum chloride, 20 parts of aluminum citrate, 420 parts of ethylene glycol, and 310 parts of deionized water are used to control the temperature of the material at 35 °C with a constant temperature water bath, and stir for 1 h. A light yellow translucent solution was obtained, and an appropriate amount of deionized water was added to adjust the mass concentration of the product system to 30%. Sodium perborate is 0.2% (to the working liquid wt%), and formic acid is 1.2% (to the working liquid wt%), and the two are directly added into the rolling groove working liquid respectively when the fabric is processed.

Embodiment 3

[0029] Mix 120 parts of glyoxal (40%), 90 parts of aluminum phosphate, 10 parts of aluminum tartrate, 460 parts of diethylene glycol, and 320 parts of deionized water. Use a constant temperature water bath to control the temperature of the material at 40 ° C. Stir for 1 hour to obtain light yellow Translucent solution, add appropriate amount of deionized water to adjust the mass concentration of the product system to 30%. Borax is 0.4% (to the working solution wt%), and formic acid is 1.7% (to the working solution wt%), and the two are directly added to the rolling groove working solution when fabrics are processed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com