Production method of shadow mask type plasma display board front plate metal electrode

A technology of plasma and production method, which is applied in the production of metal electrodes on the front plate of plasma display panels, and in the field of production of metal electrodes on plasma displays, which can solve the problems of high manufacturing cost and poor quality of front plate metal electrodes, and reduce production costs , slow down the rate, reduce the effect of firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

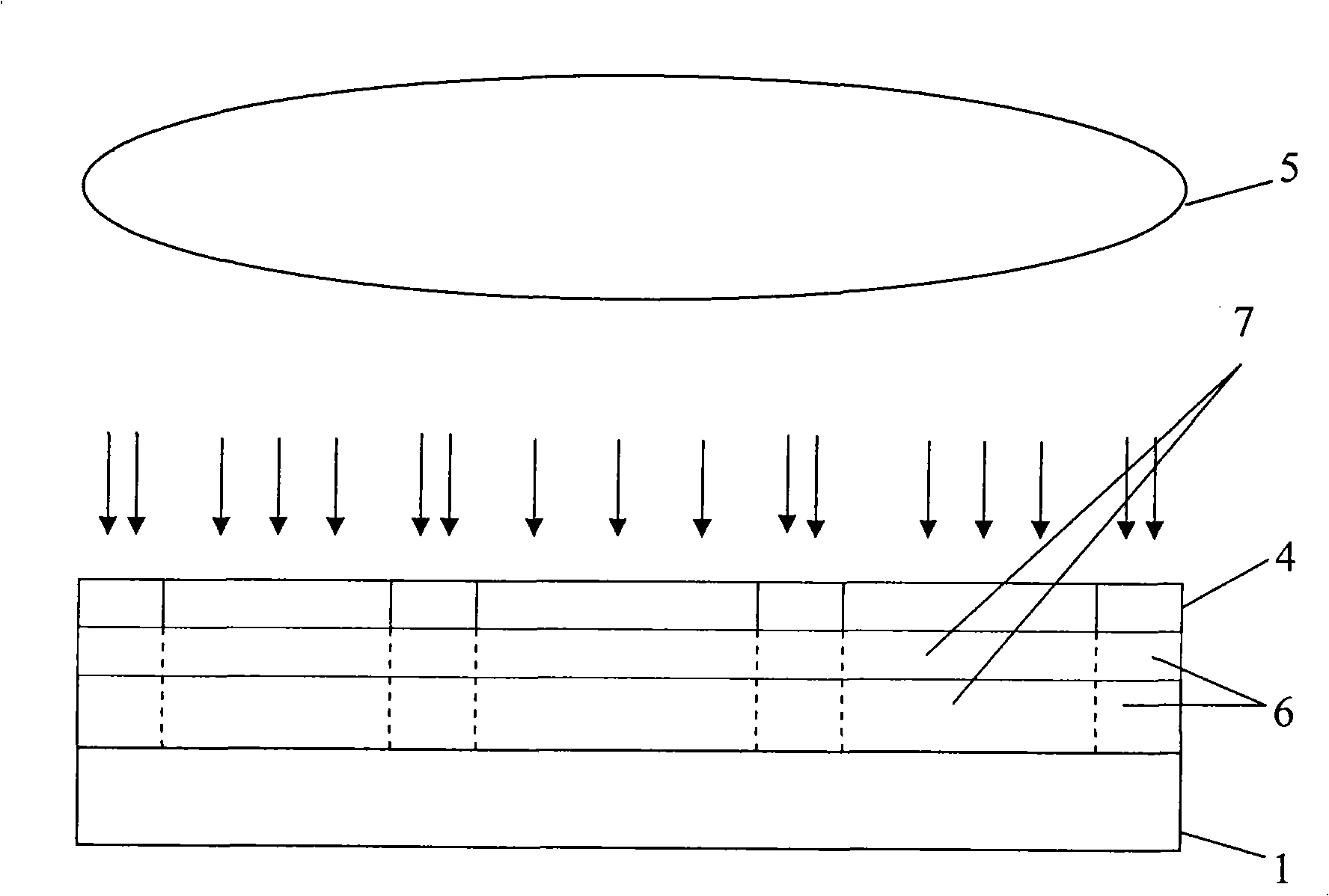

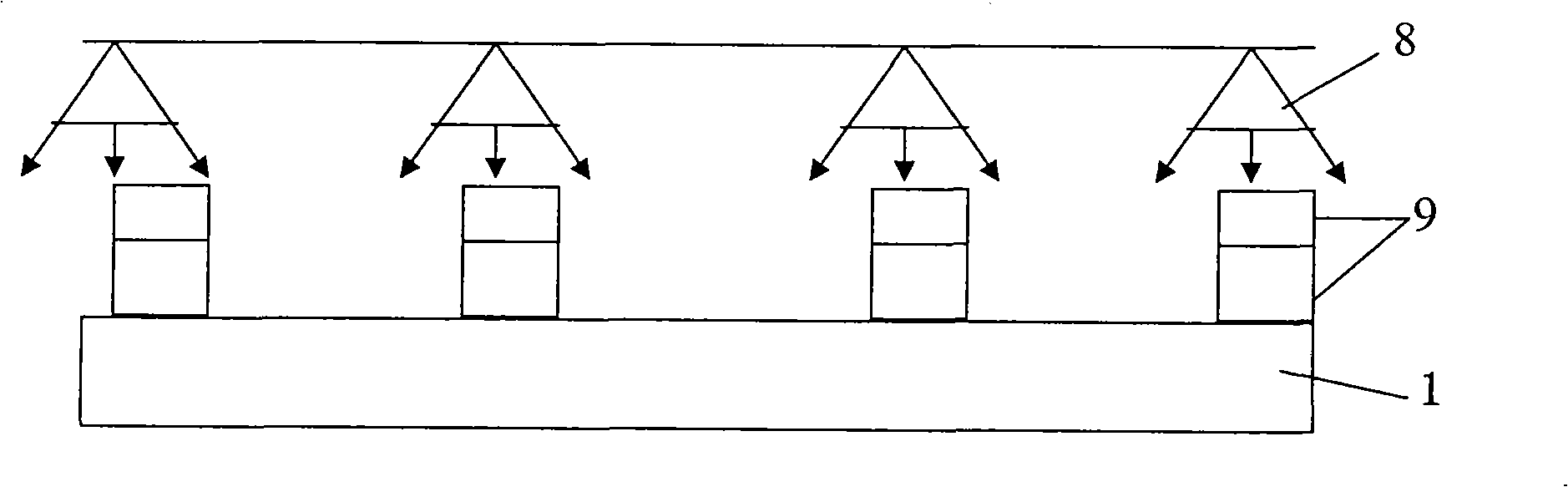

[0030] A method for manufacturing a metal electrode on a front plate of a shadow mask type plasma display panel, the specific steps are as follows:

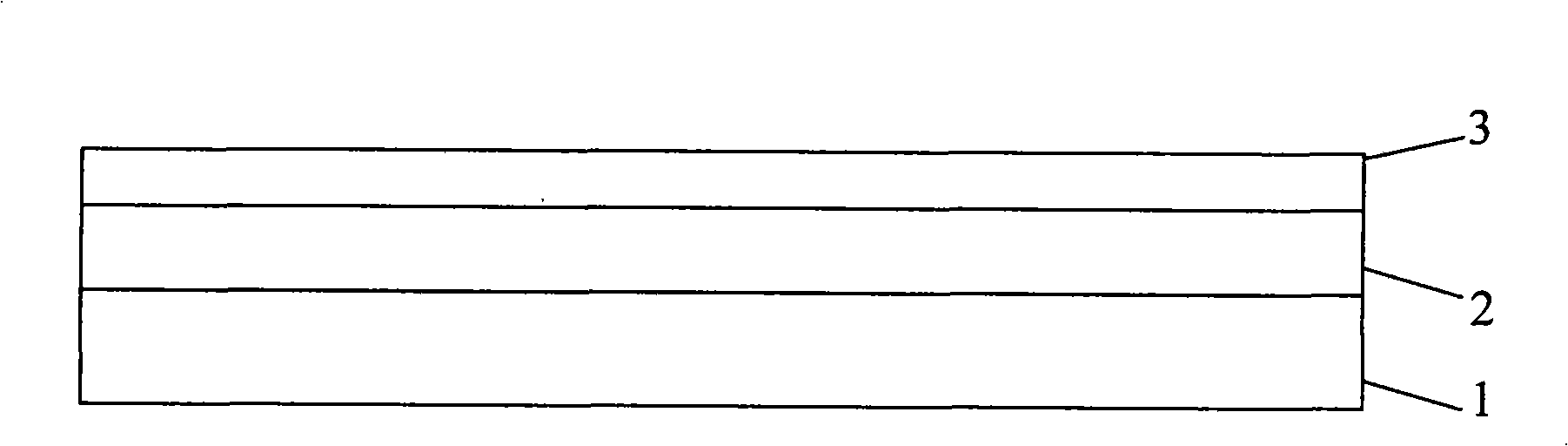

[0031] 1. Clean the common soda-lime glass substrate 1.

[0032] 2. Slurry preparation, put the black glass slurry 2 and white photosensitive silver slurry 3 into a clean mixing box and weigh them, put them into the stirring and defoaming machine, adjust the balance according to the weight of the slurry, and set the stirring and defoaming time After the slurry has been stirred and defoamed, it is taken out from the mixer and cooled to room temperature.

[0033] 3. A layer of black glass paste 2 is evenly coated on the front substrate through multiple printings by using screen printing technology, and the printing thickness of the black glass paste 2 is 18-40 μm.

[0034] The specific operation process of each printing is: the black glass paste 2 prepared in the previous process is evenly coated on a certain mesh screen, the prin...

Embodiment 2

[0046] In the above-mentioned embodiment 1, the cured paste with the electrode pattern is sintered under the firing conditions of 550°C and 40 minutes of heat preservation, which constitutes the second group of embodiments of the present invention.

Embodiment 3

[0048] In the above-mentioned embodiment 1, the cured paste with the electrode pattern is sintered under the firing conditions of 540°C and 50 minutes of heat preservation, which constitutes the third group of embodiments of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com