Polyvinyl chloride auxiliary heat stabilizer and preparation method thereof

An auxiliary heat stabilizer, polyvinyl chloride technology, applied in the field of polyvinyl chloride auxiliary heat stabilizer and its preparation, can solve problems such as high cost, stability that cannot meet application requirements, and limited application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

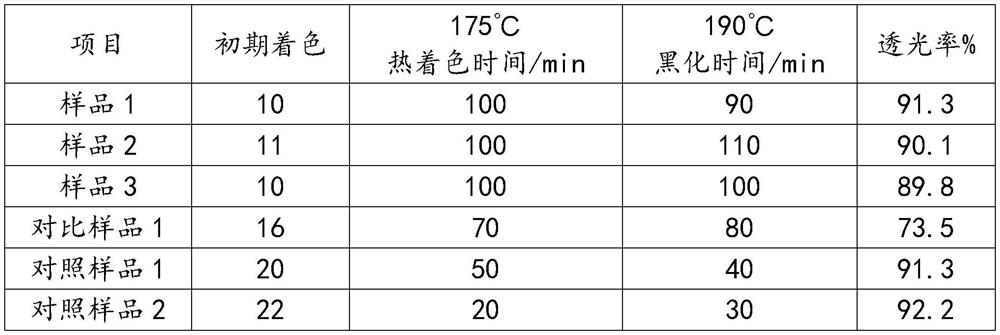

Examples

Embodiment 1

[0034] A polyvinyl chloride auxiliary heat stabilizer, comprising component A, component B and modified hydrotalcite;

[0035] This polyvinyl chloride auxiliary heat stabilizer is prepared through the following steps:

[0036]The first step, preparing component A and component B;

[0037] Second step, prepare modified hydrotalcite;

[0038] The third step is to mix component A and component B according to the weight ratio of 1:1 to obtain the first component, and then to mix the modified hydrotalcite and stearic acid according to the mass ratio of 1:1 to obtain the second component. The two components and the first component are mixed according to the mass ratio of 7:1 to obtain a polyvinyl chloride auxiliary heat stabilizer.

[0039] Wherein, preparation component A comprises the steps:

[0040] Step A11, add xylene, methyl stearate and sodium methoxide into a four-necked flask, set the temperature to 140°C, and the rotation speed to 300r / min, add acetophenone dropwise whi...

Embodiment 2

[0052] A polyvinyl chloride auxiliary heat stabilizer, comprising component A, component B and modified hydrotalcite;

[0053] This polyvinyl chloride auxiliary heat stabilizer is prepared through the following steps:

[0054] The first step, preparing component A and component B;

[0055] Second step, prepare modified hydrotalcite;

[0056] The third step is to mix component A and component B according to the weight ratio of 1:1 to obtain the first component, and then to mix the modified hydrotalcite and stearic acid according to the mass ratio of 1:2 to obtain the second component. The two components and the first component are mixed according to the mass ratio of 8:1 to obtain a polyvinyl chloride auxiliary heat stabilizer.

[0057] Wherein, preparation component A comprises the steps:

[0058] Step A11, add xylene, methyl stearate and sodium methoxide into a four-necked flask, set the temperature to 140°C, and the rotation speed to 300r / min, add acetophenone dropwise wh...

Embodiment 3

[0070] A polyvinyl chloride auxiliary heat stabilizer, comprising component A, component B and modified hydrotalcite;

[0071] This polyvinyl chloride auxiliary heat stabilizer is prepared through the following steps:

[0072] The first step, preparing component A and component B;

[0073] Second step, prepare modified hydrotalcite;

[0074] The third step is to mix component A and component B according to the weight ratio of 1:1 to obtain the first component, and then to mix the modified hydrotalcite and stearic acid according to the mass ratio of 1:3 to obtain the second component. The two components and the first component are mixed according to the mass ratio of 9:1 to obtain a polyvinyl chloride auxiliary heat stabilizer.

[0075] Wherein, preparation component A comprises the steps:

[0076] Step A11, add xylene, methyl stearate and sodium methoxide into a four-necked flask, set the temperature to 140°C, and the rotation speed to 300r / min, add acetophenone dropwise wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com