Treatment method of desulfurization wastewater

A treatment method and desulfurization wastewater technology, applied in water/sewage treatment, heating water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problems of large evaporation, large equipment investment, high energy consumption, and reduce water volume , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

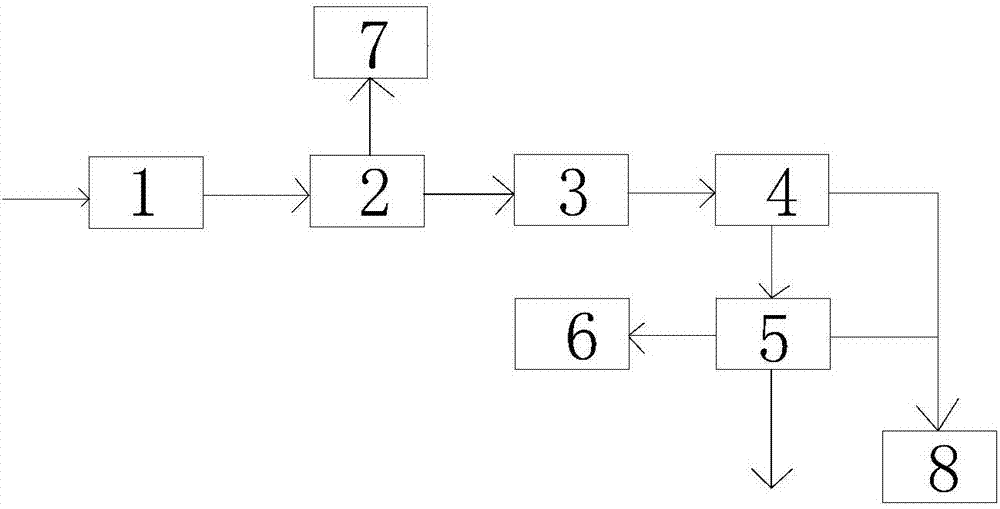

Method used

Image

Examples

Embodiment 1

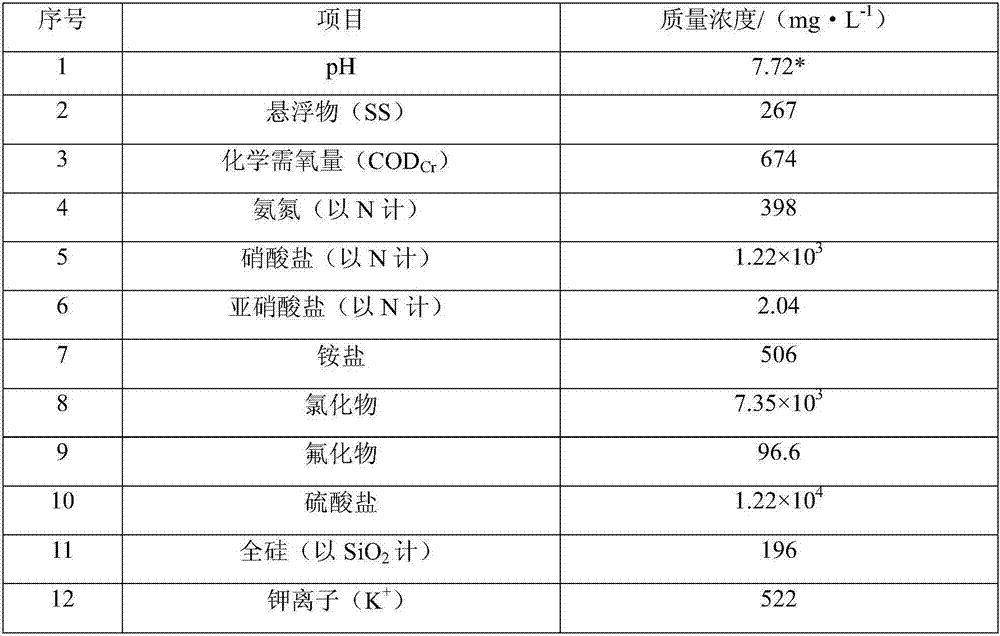

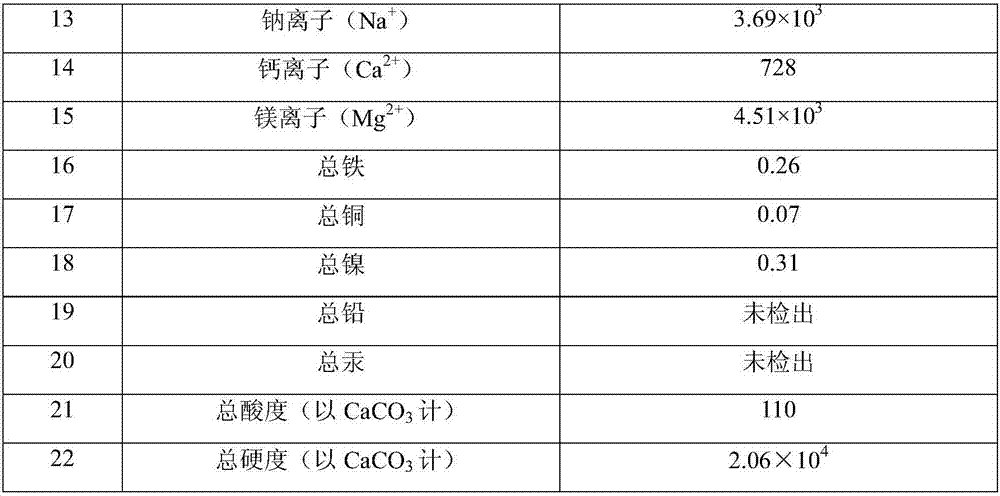

[0046] This embodiment is used to illustrate the treatment method of desulfurization wastewater provided by the present invention

[0047] In the stirring state, add lime to the desulfurization wastewater, control the pH of the neutralized wastewater to be 11, and then add organic sulfur (0.003kg / m 3 desulfurization wastewater), sodium sulfate (33.8kg / m 3 desulfurization wastewater) and sodium carbonate (1.38kg / m 3 Desulfurization waste water) is stirred evenly and then precipitated. Add flocculant polyferric sulfate (0.09kg / m 3 desulfurization wastewater) and coagulant polyacrylamide (0.0005kg / m 3 desulfurization wastewater) for flocculation treatment. Then static sedimentation was carried out in the inclined plate sedimentation tank to realize solid-liquid separation. The supernatant is adjusted to pH 7 by adding acid and then subjected to ultrafiltration, and the bottom sludge is filtered by a filter press and then shipped out.

[0048] The conditions of the ultrafilt...

Embodiment 2

[0051] This embodiment is used to illustrate the treatment method of desulfurization wastewater provided by the present invention

[0052] In the stirring state, add lime to the desulfurization wastewater, control the pH of the neutralized wastewater to be 11, and then add organic sulfur (0.004kg / m 3 desulfurization wastewater), sodium sulfate (35kg / m 3 desulfurization wastewater) and sodium carbonate (1.1kg / m 3 Desulfurization waste water) is stirred evenly and then precipitated. Add flocculant polyferric sulfate (0.08kg / m 3 desulfurization wastewater) and coagulant polyacrylamide (0.0006kg / m 3 desulfurization wastewater) for flocculation treatment. Then static sedimentation was carried out in the inclined plate sedimentation tank to realize solid-liquid separation. The supernatant is adjusted to pH 8 by adding acid and then subjected to ultrafiltration, and the bottom sludge is filtered by a filter press and then transported outside.

[0053] The conditions of the ultr...

Embodiment 3

[0056] This embodiment is used to illustrate the treatment method of desulfurization wastewater provided by the present invention

[0057] In the stirring state, add lime to the desulfurization wastewater, control the pH of the neutralized wastewater to be 11, and then add organic sulfur (0.005kg / m 3 desulfurization wastewater), sodium sulfate (35.6kg / m 3 desulfurization wastewater) and sodium carbonate (1.0kg / m 3 Desulfurization waste water) is stirred evenly and then precipitated. Add flocculant polyaluminum chloride (0.09kg / m 3 desulfurization wastewater) and coagulant polyacrylamide (0.0004kg / m 3desulfurization wastewater) for flocculation treatment. Then static sedimentation was carried out in the inclined plate sedimentation tank to realize solid-liquid separation. The supernatant is adjusted to a pH of 9 by adding acid and then subjected to ultrafiltration, and the bottom sludge is filtered by a filter press and then shipped out.

[0058] The conditions of the ult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com