Leather making bio-pretreatment method

A biological and process technology, applied in the field of tanning biological pretreatment, can solve the problems of large water consumption and ecological environment hazards, and achieve the effect of reducing the use of lime, reducing the content of suspended solids, and reducing the load of COD and BOD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

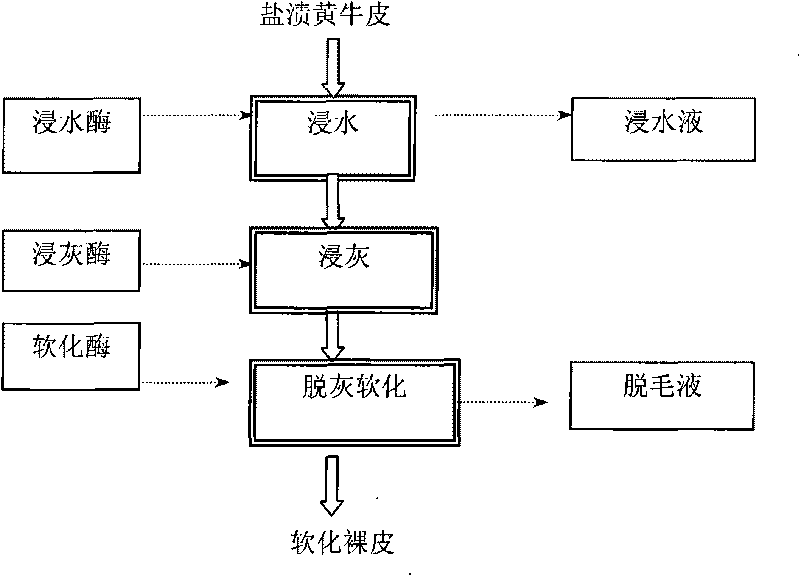

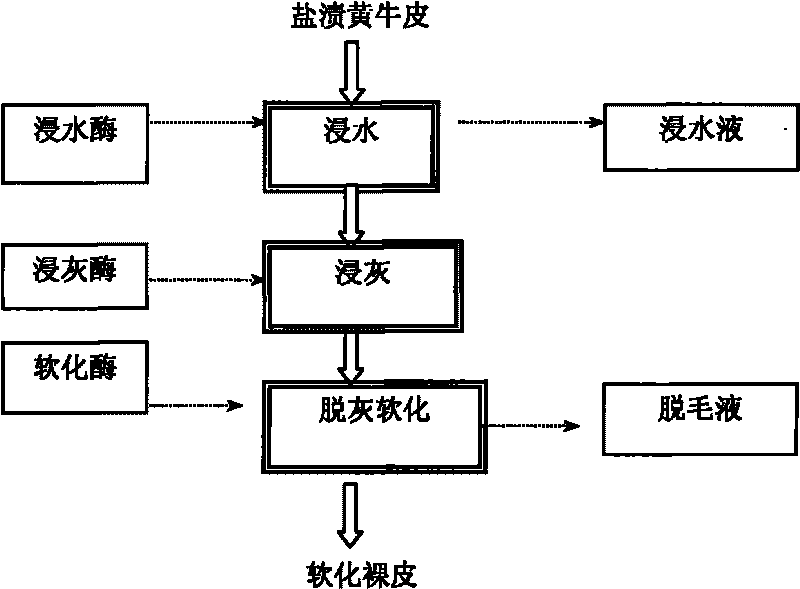

[0017] Now illustrate the present invention in conjunction with accompanying drawing and embodiment.

[0018] The key technology of the invention is to replace the traditional chemical method with the biotechnology based on the biological enzyme agent to treat the raw hides, so as to remove the protein components on the raw hides which are irrelevant to tanning.

[0019] The processing objects of each process in the preparation section are mainly various proteins (such as keratin, collagen, reticulin, elastin and albumin, globulin, proteoglycan in the fibrous matrix, etc.) and fats. Due to the high efficiency and specificity of enzymes, in each process of the preparation section, various enzyme preparations can be selected and used according to the needs of the objects they act on, so as to achieve the desired effect with a small amount and reduce harmful effects. The use of substances shortens the processing time and improves or improves the quality of the finished leather. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com