Method for pretreating organic wastewater

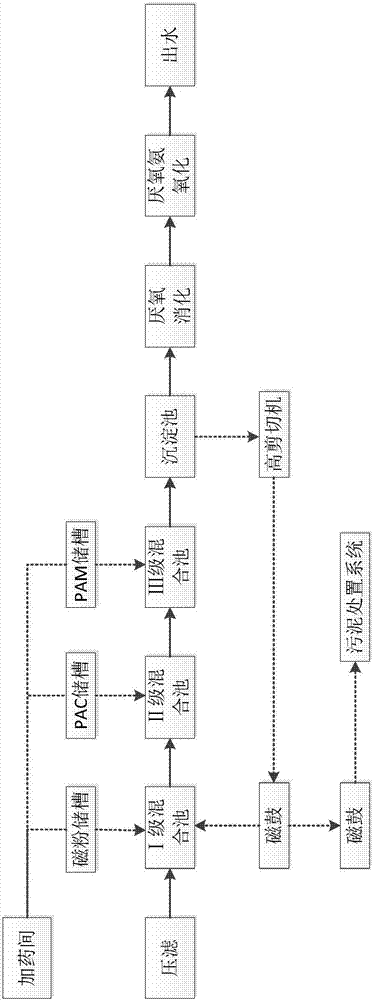

A technology for organic wastewater and pretreatment, which is applied in animal husbandry wastewater treatment, multi-stage water treatment, water/sewage treatment, etc. It can solve the problems of endangering livestock and human health, hindering the popularization and application of technology, and large volume of high-concentration wastewater. Improve the floc structure and density, improve the floc sedimentation performance, and strengthen the treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preprocessing method of the present embodiment is as follows:

[0040] (1) Add Fe 3 o 4 With the magnetic seed as the main component, stir rapidly at a speed of 400r / min for 1min;

[0041] (2) Add flocculant PAC and stir rapidly at a speed of 300r / min for 1.5min;

[0042] (3) Add the coagulant PAM, first stir at a speed of 300r / min for 10s, and then stir at a speed of 70r / min for 110s;

[0043] (4) Drain and discharge mud after standing for 10 minutes.

[0044] After the livestock and poultry breeding wastewater in this example is pretreated, the COD has been reduced to 4150 mg / L, with a removal rate of 70.3%, and the total phosphorus has been reduced to 8 mg / L, with a removal rate of 95%.

Embodiment 2

[0046] The preprocessing method of the present embodiment is as follows:

[0047] (1) Add Fe 3 o 4 With magnetic seeds as the main component, stir rapidly at a speed of 350r / min for 80s;

[0048] (2) Add flocculant PAC and stir rapidly at a speed of 250r / min for 80s;

[0049] (3) Add the coagulant PAM, first stir at a speed of 250r / min for 15s, and then stir at a speed of 60r / min for 100s;

[0050] (4) Drainage and mud discharge after standing for 15 minutes.

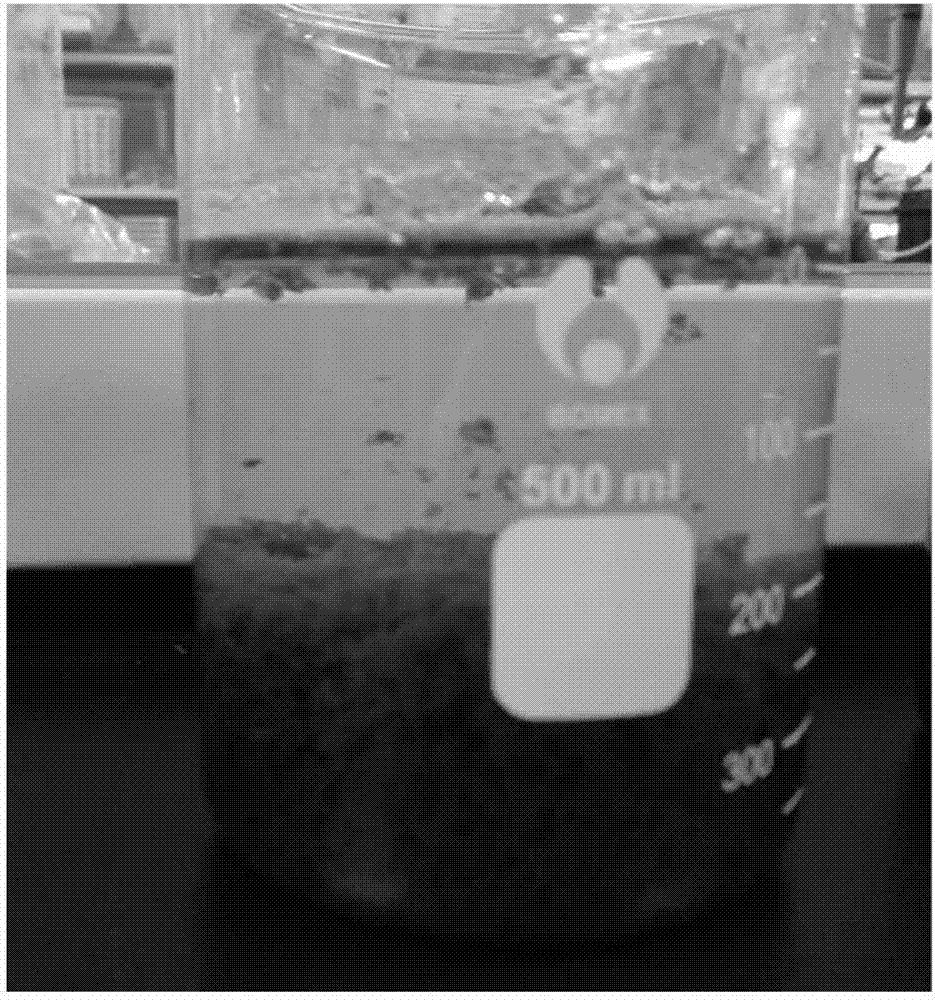

[0051] After the livestock and poultry breeding wastewater in this example is pretreated, the COD removal rate is 61.7%, the total phosphorus is reduced to 12mg / L, the removal rate is 92.5%, and the floc volume is reduced by 45% compared with the ordinary coagulation process. Pretreated livestock and poultry farming wastewater such as figure 2 shown.

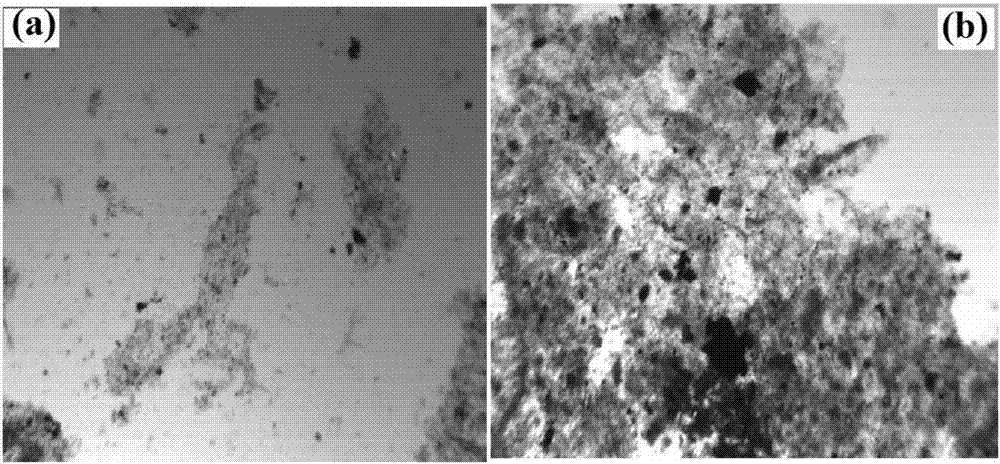

[0052] The contrast treatment method that only includes steps (1), (2) has loose flocs, and the pictures compared with the pretreatment methods that include steps ...

Embodiment 3

[0054] The preprocessing method of the present embodiment is as follows:

[0055] (1) Add Fe to the landfill leachate with high solid content and high concentration to be treated 3 o 4With magnetic seeds as the main component, stir rapidly at a speed of 370r / min for 80s;

[0056] (2) Add flocculant PAC and stir rapidly at a speed of 350r / min for 70s;

[0057] (3) Add the coagulant PAM, first stir at a speed of 200r / min for 15s, and then stir at a speed of 50r / min for 120s;

[0058] (4) Drainage and mud discharge after standing for 15 minutes.

[0059] After the livestock and poultry breeding wastewater in this embodiment is pretreated, the COD is reduced from 1885mg / L to 643mg / L, the removal rate is 65.9%, and the color of landfill leachate changes from dark brown to light.

[0060] In some other specific embodiments of the present invention, the speed of the fast stirring can also be other values in the range of 150-400r / min, and the speed of the slow stirring can also ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com