Method for preparing improved water washing treating agent

An improved technology for water washing treatment, applied in water/sludge/sewage treatment, sludge treatment, detergent compounding agent, etc. Cleaning effect, improve cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

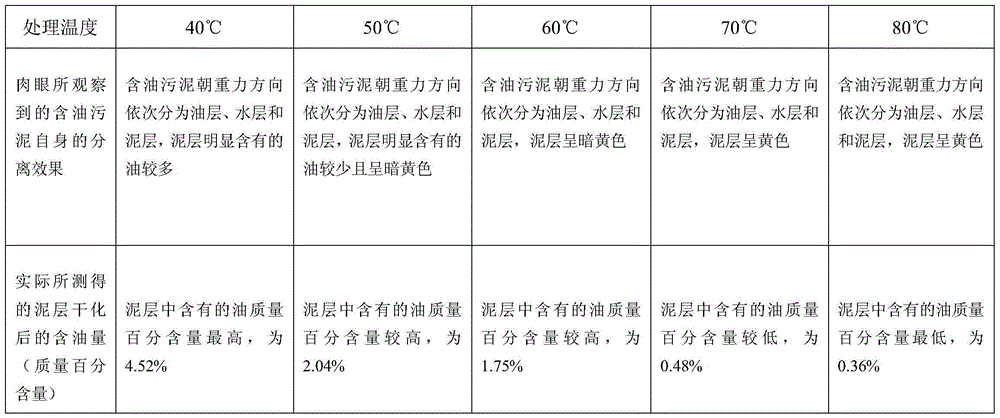

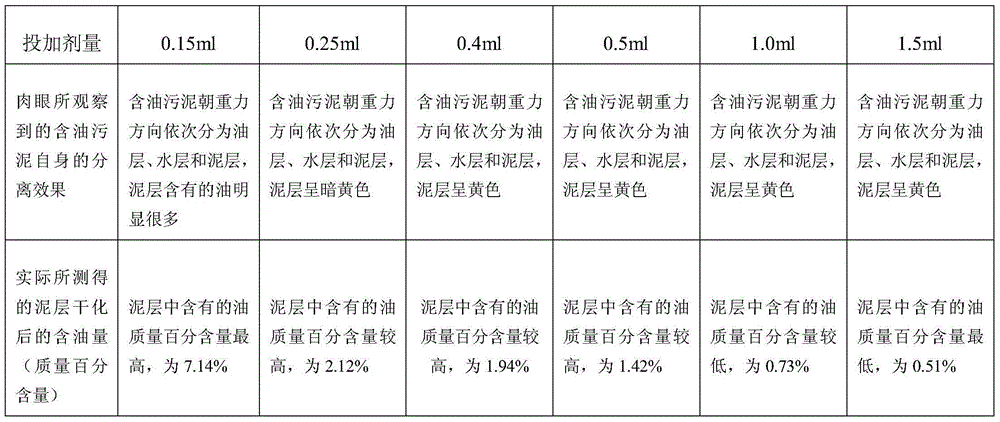

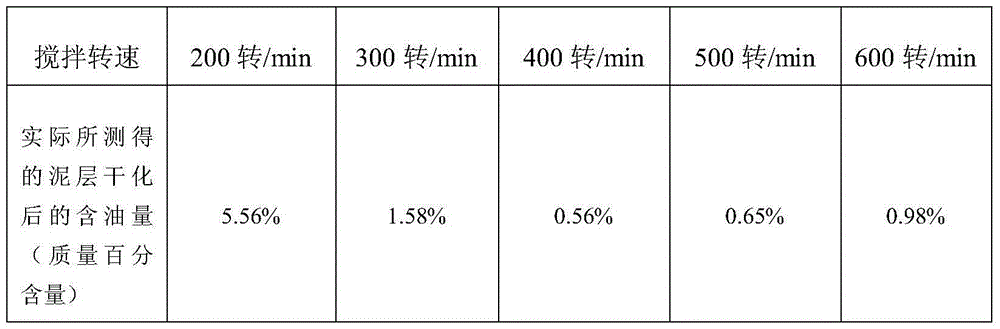

Examples

Embodiment Construction

[0011] A method for preparing an improved washing treatment agent, ① adding 5 (wt)%-10 (wt)% sodium dodecylbenzenesulfonate to the enamel reaction kettle, when the temperature in the enamel reaction kettle is always controlled Turn on the agitator at [50±1]°C to continuously stir sodium dodecylbenzenesulfonate at [50±1]°C; ② mix 82 ( wt)%—85(wt)% water is added to the enamel reaction kettle, and the sodium dodecylbenzenesulfonate and water that have been added to the enamel reaction kettle are continuously stirred by the stirrer for 10min to mix; During the stirring process of sodium dialkylbenzenesulfonate and water, 1 (wt)% polysorbate is gradually added in the enamel reaction kettle, sodium dodecylbenzenesulfonate, Water and polysorbate are continuously stirred by a stirrer for 10min and mixed; ④ in the process of stirring sodium dodecylbenzenesulfonate, water and polysorbate, 2(wt)%-8(wt)% hydrogen Sodium oxide, 1(wt)%-5(wt)% of sodium carbonate are added to the enamel re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com