Environment-friendly oil field sludge treating agent and preparation method thereof

An oilfield sludge, environmentally friendly technology, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of complex treatment process, uneconomical, high cost, improve cleaning effect Good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

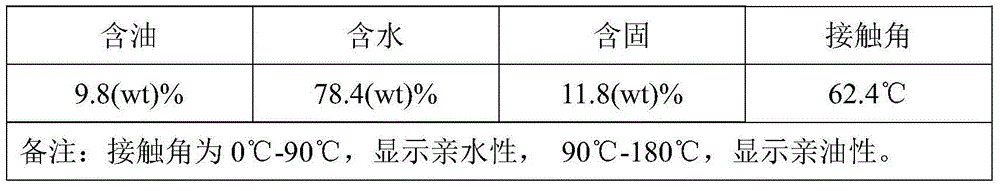

[0012] The sludge of a thin oil treatment station in an operation area of Xinjiang Oilfield was tested, and the physical properties of the sludge before treatment are shown in Table 1:

[0013] Table 1

[0014]

[0015] Apply the present invention to test the thin oil treatment station sludge of a certain operation area in Xinjiang oilfield: take by weighing sodium dodecylbenzenesulfonate 5g, sodium dodecanoate 5g, Span (60) 8g, sodium hydroxide 10g, water 72g . First add sodium dodecylbenzenesulfonate and sodium dodecanoate into the reaction kettle, add water and stir for 10 minutes, control the temperature at 50°C, then add sodium hydroxide, stir for 5 minutes, then add Span (60), continue stirring After 10 minutes, an environment-friendly treatment agent for oily sludge in oilfields can be prepared. Then mix 50g of washing agent with 100ml of 50°C hot water, then add 0.5ml of washing agent, stir for 10 minutes at a speed of 300 rpm, and let it stand for 1 hour. The s...

Embodiment 2

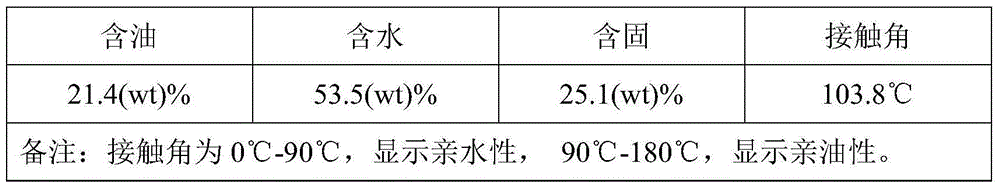

[0019] The sludge of a heavy oil treatment station in an operation area of Xinjiang Oilfield was tested, and the physical properties of the sludge before treatment are shown in Table 3:

[0020] table 3

[0021]

[0022] Apply the present invention to the thin oil treatment station sludge of a certain operation area in Xinjiang Oilfield to test: take by weighing sodium dodecylbenzene sulfonate 8g, Span (80) 10g, sodium hydroxide 15g, water 72g. First add sodium dodecylbenzenesulfonate into the reaction kettle, add water and stir for 10 minutes, control the temperature at 50°C, then add sodium hydroxide, stir for 5 minutes, then add Span (80), and continue stirring for 10 minutes to obtain Environmentally friendly oily sludge treatment agent, mix 50g of washing agent with 100ml of 80°C hot water, then add 0.5ml of washing agent, stir for 10 minutes at a speed of 500 rpm, let stand for 1 hour, and remove the bottom sludge Centrifugation, upper oil slick and sewage recovery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com