Anti-blocking baffling type percolation dam

A baffled and seepage dam technology, applied in the field of river environmental management, can solve the problems of clogging of seepage dams, water flow direction, single purification method, limited water purification capacity, etc. Good purification and landscape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

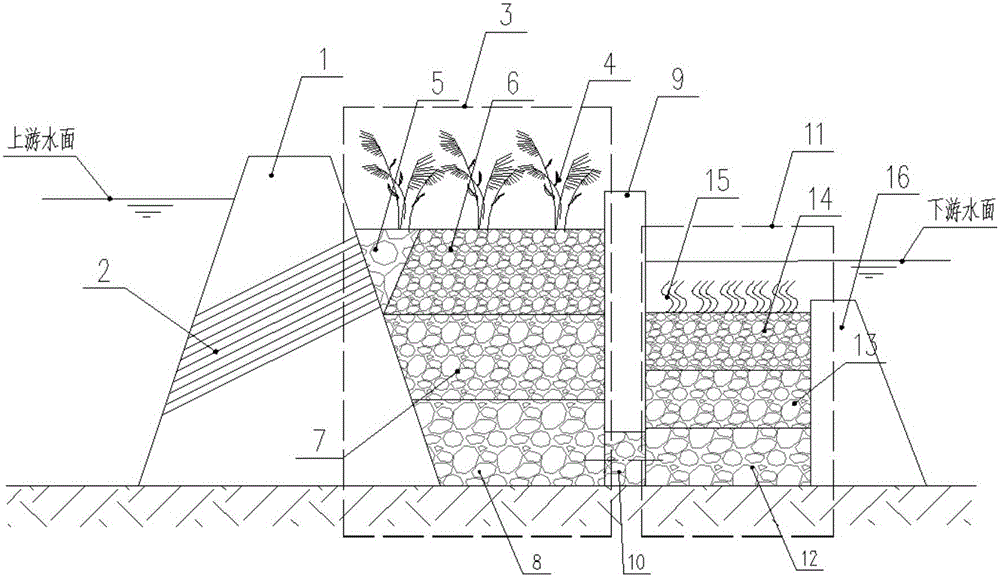

[0030] An anti-blocking deflection type seepage dam, comprising a dam 1 and a side wall 16 arranged on the downstream side of the dam 1, a partition wall 9 is arranged between the dam 1 and the side wall 16,

[0031] The downward infiltration zone 3 is formed between the dam 1 and the partition wall 9, and the upward infiltration zone 11 is formed between the partition wall 9 and the side wall 16.

[0032] The first vegetation layer 4, the first gravel packing layer 5, the second gravel packing layer 6, the third gravel packing layer 7 and the fourth gravel packing layer 8 are arranged in the descending infiltration zone 3, and the first gravel packing layer 5 and the The two gravel packing layers 6 are located on the same layer, the first vegetation layer 4 is arranged on the first gravel packing layer 5 and the second gravel packing layer 6, and the third gravel is arranged successively under the first gravel packing layer 5 and the second gravel packing layer 6 Packing laye...

Embodiment 2

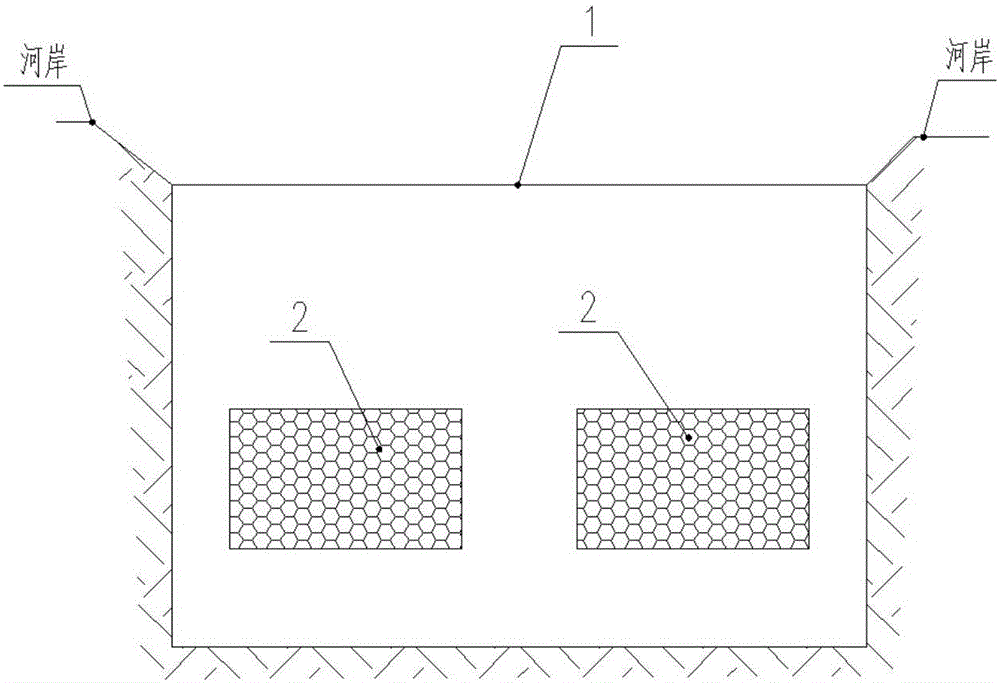

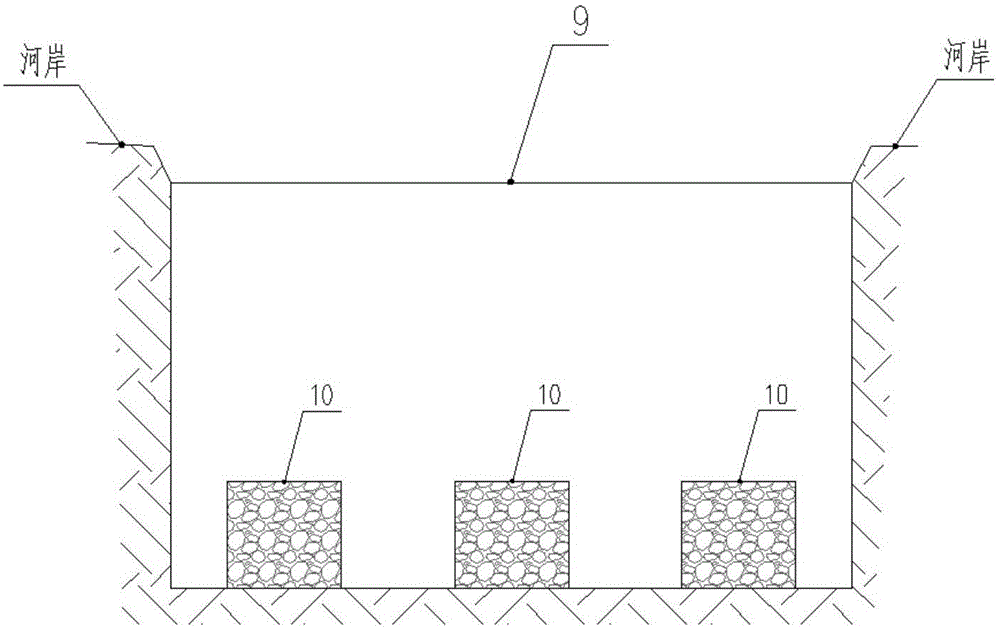

[0043] Such as Figure 1 ~ Figure 3 As shown, an anti-blocking deflection type seepage dam includes a retaining dam 1 , a downward infiltration area 3 , a partition wall 9 , an upward infiltration area 11 , and a side wall 16 . The downward infiltration zone 3 is formed between the dam 1 and the partition wall 9 , and the upward infiltration zone 11 is formed between the partition wall 9 and the side wall 16 .

[0044] Among them, the water inlet inclined pipe 2 is arranged in the middle of the dam body of the dam 1; the first vegetation layer 4, the first gravel packing layer 5, the second gravel packing layer 6, the third gravel packing layer 7, the Four gravel packing layers 8, the first gravel packing layer 5 and the second gravel packing layer 6 are located at the same layer, the first vegetation layer 4 is arranged on the first gravel packing layer 5 and the second gravel packing layer 6, the first gravel packing layer 5 and the second gravel packing layer 6, the third ...

Embodiment 3

[0059] The difference between embodiment 3 and embodiment 2 is:

[0060] Dam 1 has a height of 1.6m, a width of 3.2m, a thickness of 0.7m at the top, and a thickness of 1.7m at the bottom; inclined water inlet pipe 2 adopts UPVC hexagonal honeycomb inclined pipe, and the inclined water inlet pipe 2 is set in two groups, and the section size of each group is Width × height = 1m × 0.5m, the water inlet end of the inclined pipe is 0.3m higher than the bottom of the dam, the hexagonal honeycomb aperture of the inclined pipe is 50mm, and the angle between the inclined pipe 2 and the water surface is 40°; the first vegetation layer 4 Planting plants are calamus, and the planting density is 25 plants / m 2 ; The first gravel packing layer 5 covers the outlet end of the water inlet inclined pipe 2, the thickness (height) is 0.4m, and the gravel particle size is 50-60mm; the second gravel packing layer 6, the third gravel packing layer 7, and the fourth gravel packing Layer 8 thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com