Method for solid removal of MTO quenched water and online cleaning of water scrubber

A technology for washing towers and quenching water, applied in the chemical industry, can solve problems such as affecting the long-term stable operation of the device and affecting the production load of the MTO device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

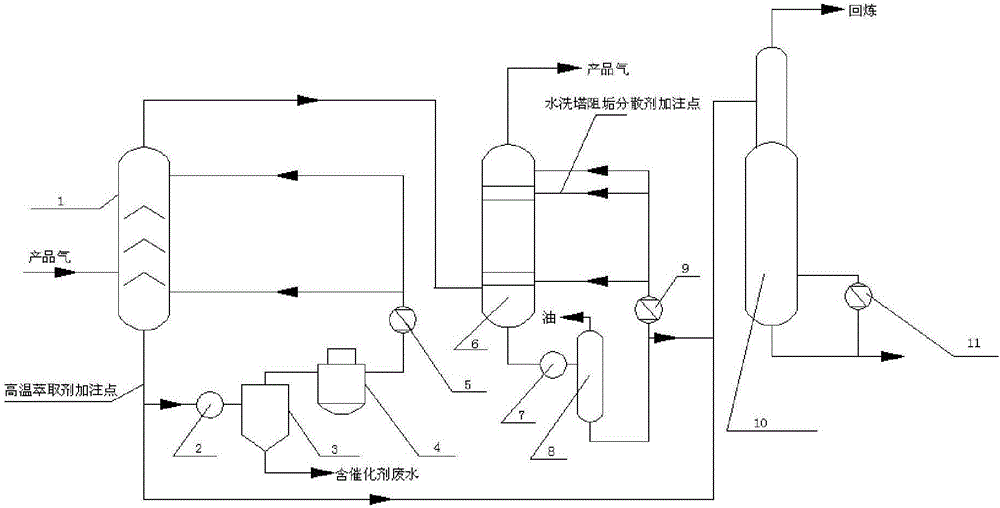

[0026] A method for MTO quenching water desolidification and washing tower online cleaning, characterized in that, the specific steps of the method are as follows:

[0027] (1) After adding high-temperature extraction agent into the quenched water drained from the bottom of quenching tower 1, it enters separation device 3, and the separated clear water is returned to quenching tower 1, and the waste water containing catalyst is discharged to the sewage treatment system;

[0028] (2) Add antiscalant and dispersant to the heavily scaled part of the washing tower 6, the agent circulates in the washing tower 6, the newly formed dirt in the washing tower 6 is discharged with the external drainage, and the trays and walls of the washing tower 6 have formed The dirt is stripped off by the antiscalant and dispersant of the water washing tower and broken into fine particles, and then discharged from the bottom of the water washing tower 6 along with the external drainage. The catalyst f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com