Decomposing titanium liquor purification method and filter for same

A filter and titanium liquid technology, applied in chemical instruments and methods, filtration separation, filtration loops, etc., to achieve the effects of reduced equipment use costs, reduced production costs, and fast installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

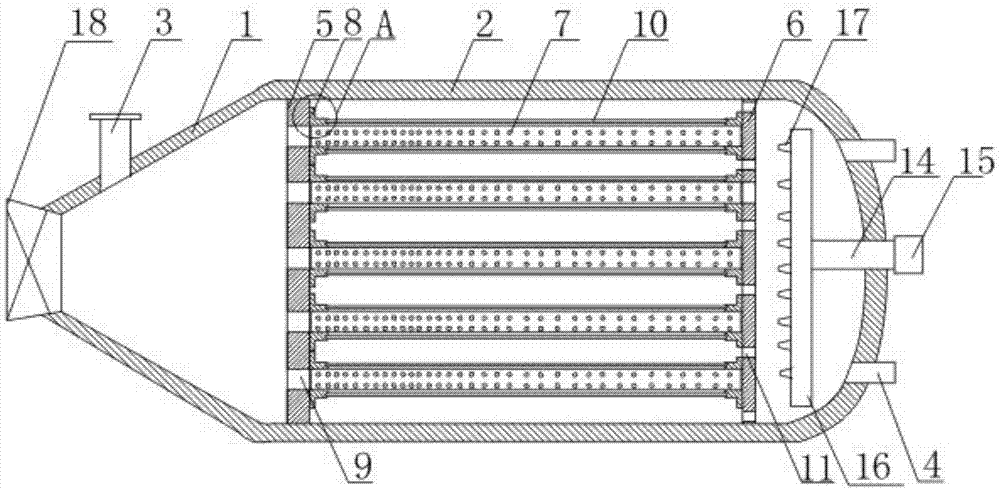

[0030] The purification method of the acidolysis titanium solution adopts the following steps: after the acidolysis titanium solution is settled, it is filtered by a tubular filter to obtain the acidolysis titanium solution.

[0031] The tubular filter includes a filter element 7 filled with diatomaceous earth.

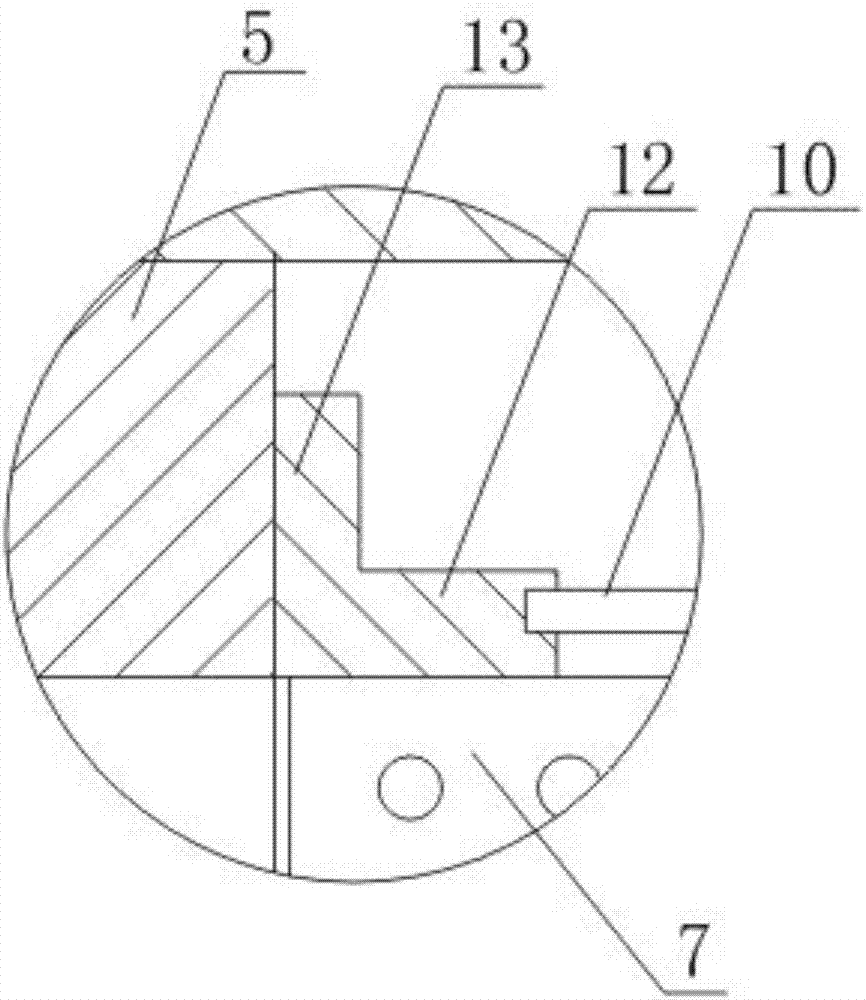

[0032] The tubular filter includes a liquid inlet tank 1 and a separation tank 2 connected to the liquid inlet tank 1, a liquid inlet 3 is provided on the side wall of the liquid inlet tank 1, and a liquid outlet 4 is provided on the end surface of the separation tank 2 The two sides of the inner cavity of the separation tank 2 are respectively provided with a positioning plate 5 and a fixed plate 6, the positioning plate 5 is arranged close to the liquid inlet tank (1), and a plurality of filter elements 7 are also arranged between the positioning plate 5 and the fixed plate 6 , the two ends of the filter element 7 are respectively connected with the positioning plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com