Filter-well circulating purification system and method for purifying river by using same

A technology for circulating purification and well filtering, applied in the field of water purification, can solve the problems of complex construction, limited water supply, and high technical requirements, and achieve the effects of reducing suspended solids content, improving effluent quality, and reducing riparian land.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

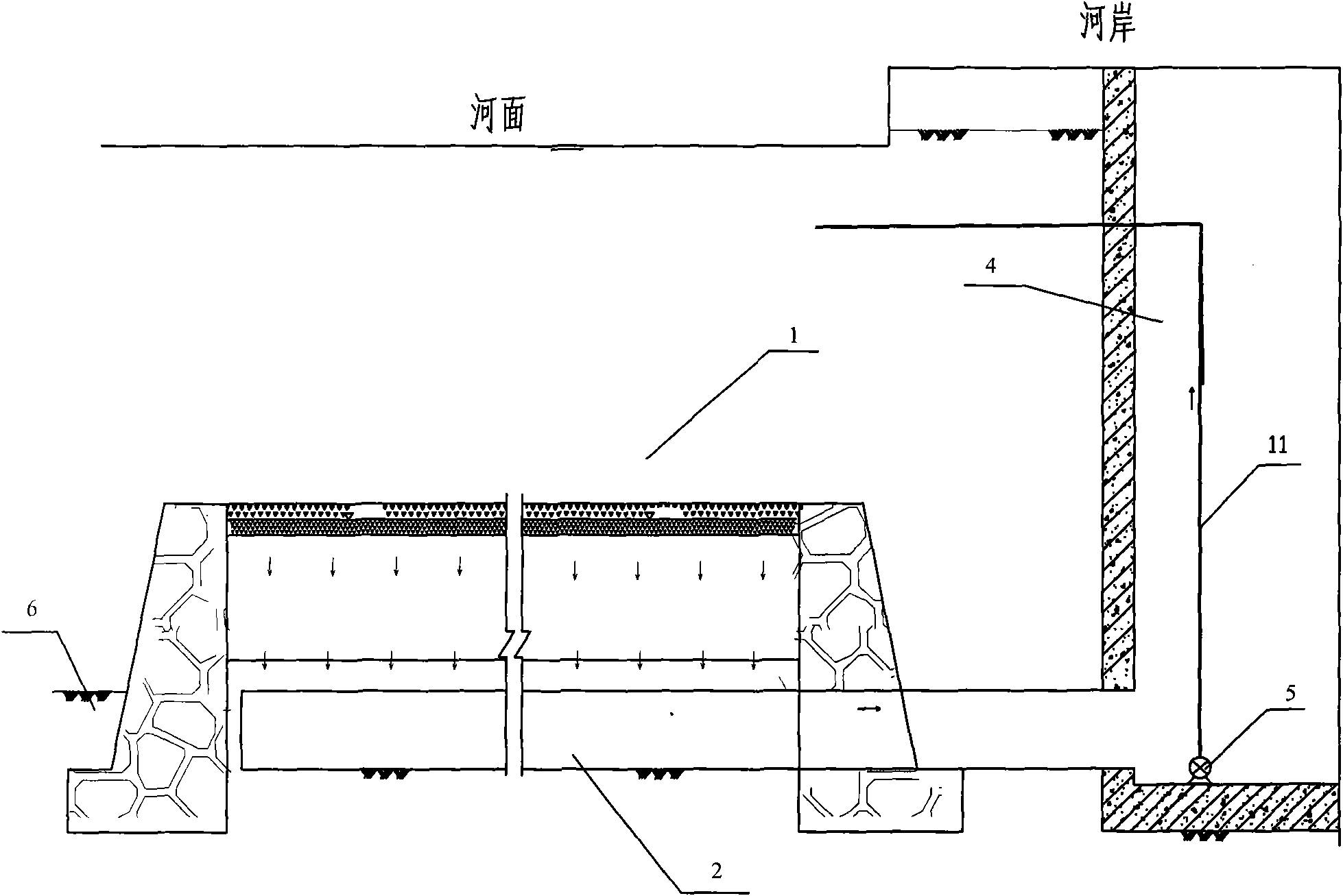

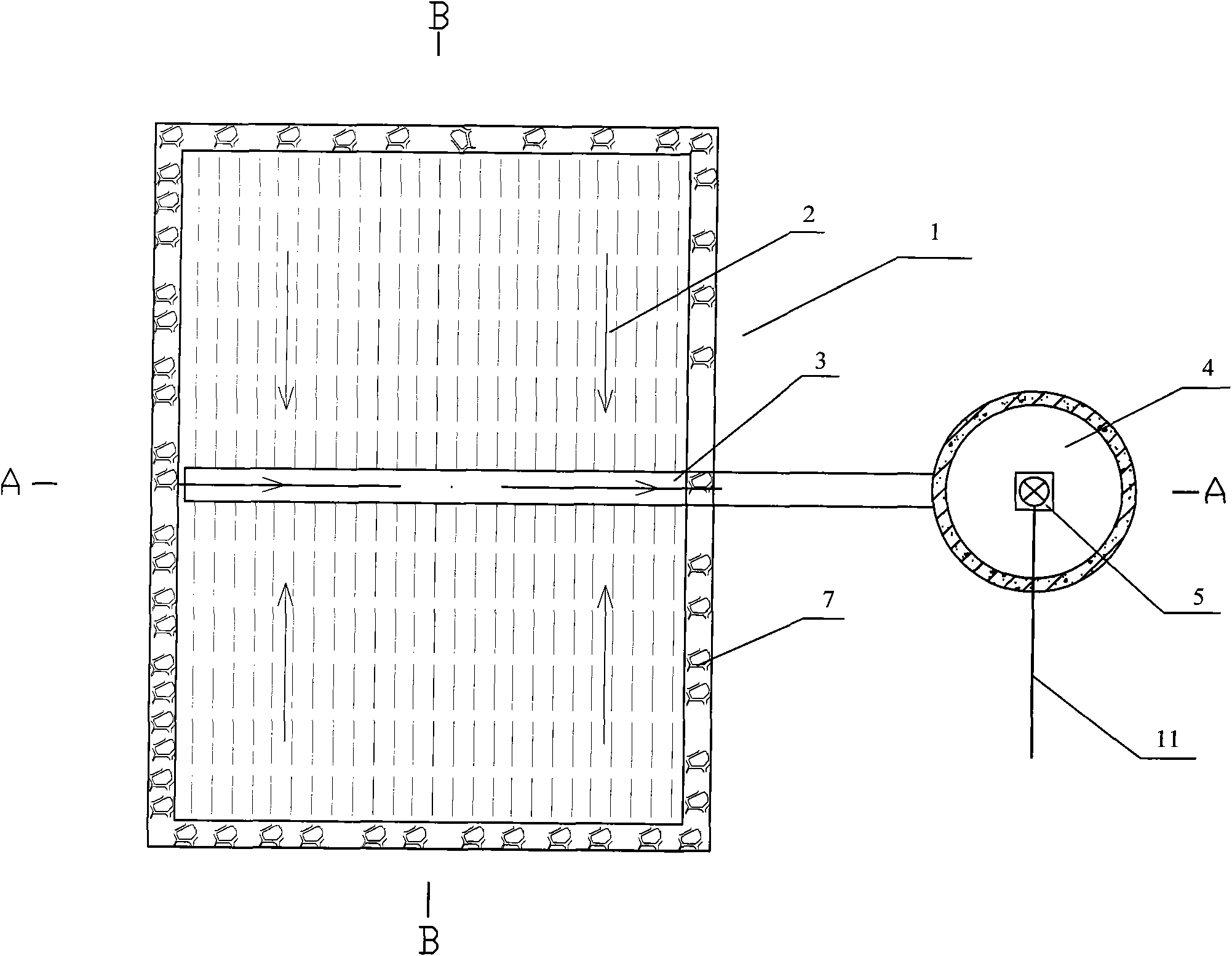

[0023] like Figure 1-3 As shown, in a preferred embodiment of the present invention, the filter well circulation purification system is made up of filter bed 1, water filter pipe 2, water collection pipe 3, filter well 4, submersible pump 5 and connecting pipeline 11;

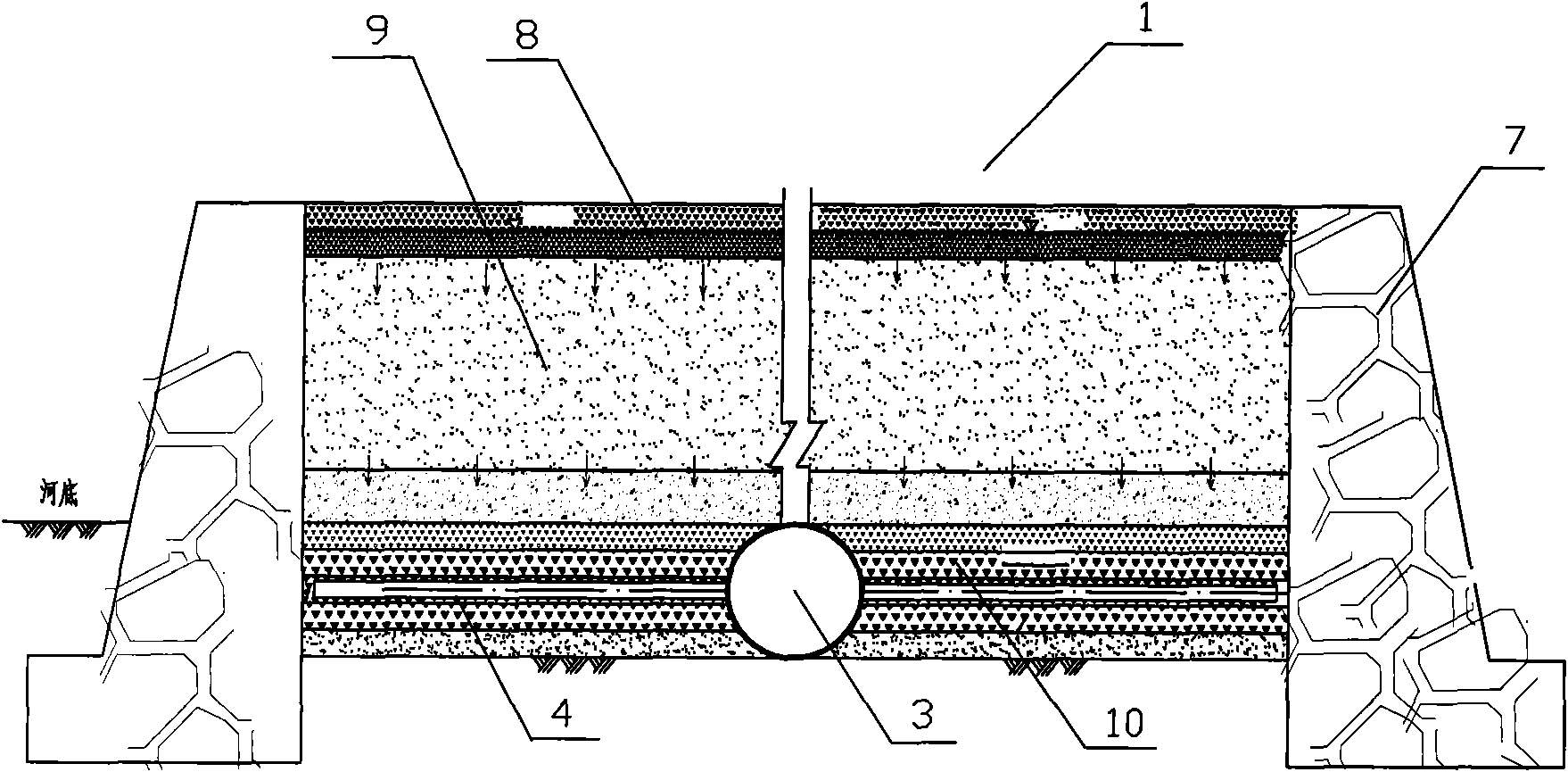

[0024] The filter bed 1 is set on the side of the river bed 6 close to the bank, its top is lower than the river water surface, the filter bed is 10m long and 7.5m wide; the filter bed 1 is semi-underground, and the bottom is located 0.5m below the river bed; the surrounding of the filter bed is The mortar masonry stone wall 7 has a wall height of 2.1m; inside the stone wall 7, an anti-scour layer 8, a filter material layer 9 and a supporting layer 10 are arranged sequentially from top to bottom; wherein, the anti-scour layer 8 includes a thickness of 100mm gravel material layer with particle size of 16-32mm and volcanic rock material layer with thickness of 100mm and particle size of about 10mm; filter materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com