Air-cooled fuel cell system and coupling heat control method thereof

A fuel cell system and fuel cell technology, applied in the direction of fuel cell heat exchange, fuel cells, fuel cell additives, etc., can solve problems such as heat loss, operation (difficult to start, increase air flow, etc.), to achieve good environmental adaptability, The effect of shortening hydrogen charging time and reducing air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Exemplary embodiments of the present invention will become apparent from the ensuing detailed description, and it should be understood that while disclosing exemplary embodiments of the present invention, the specific examples in the detailed description are for illustration purposes only, and should not be regarded as the basis for the present invention. limit range.

[0024] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

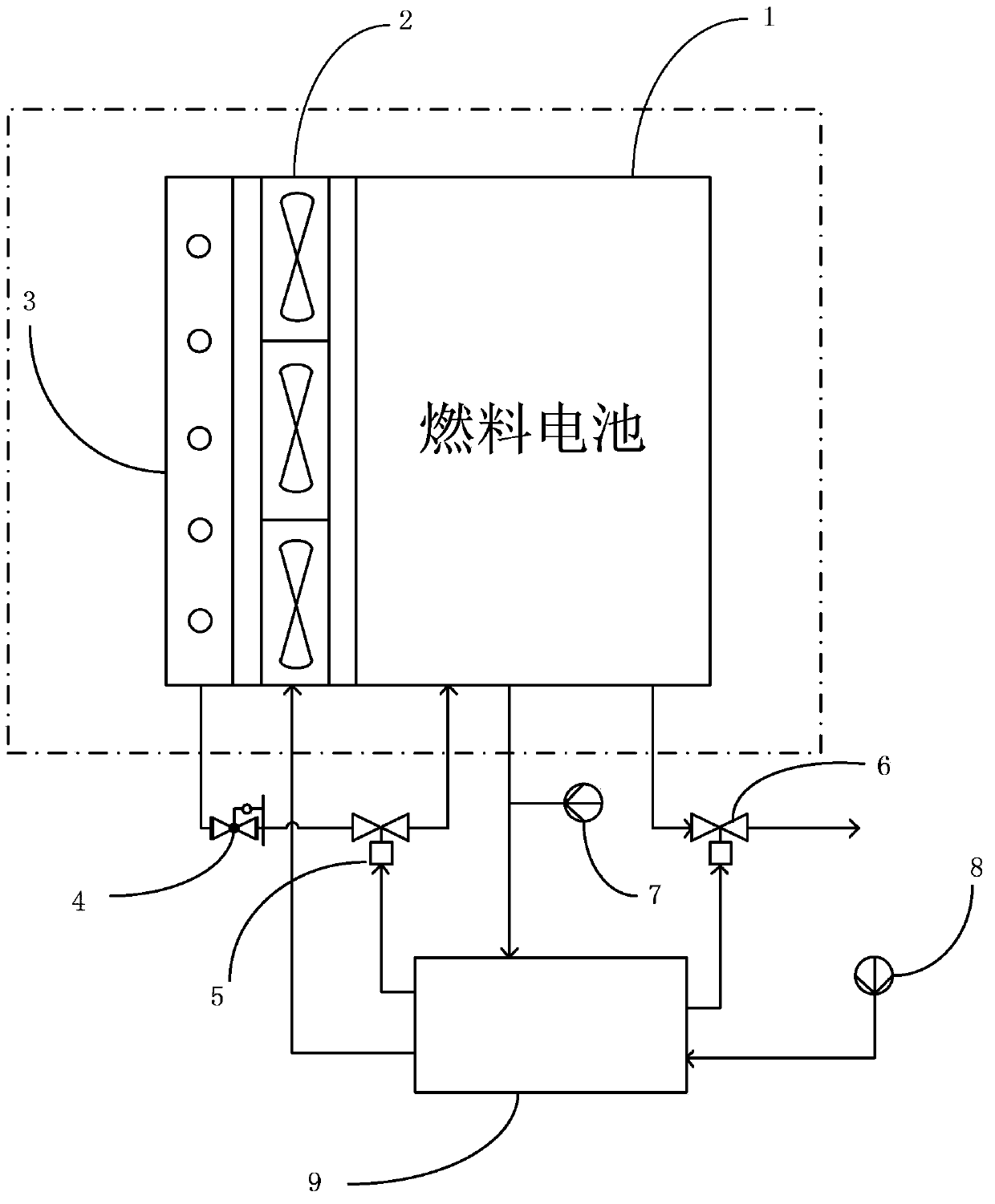

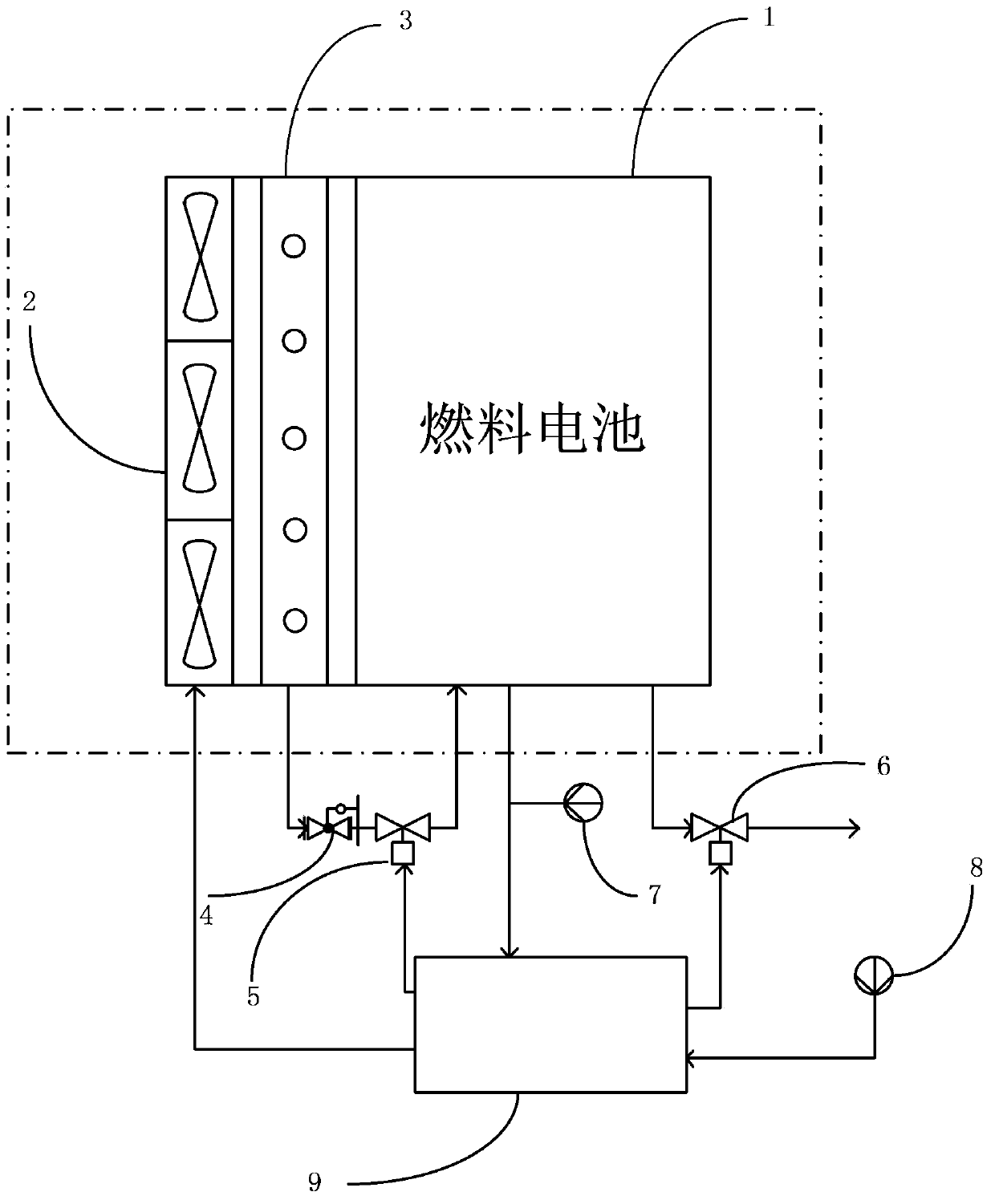

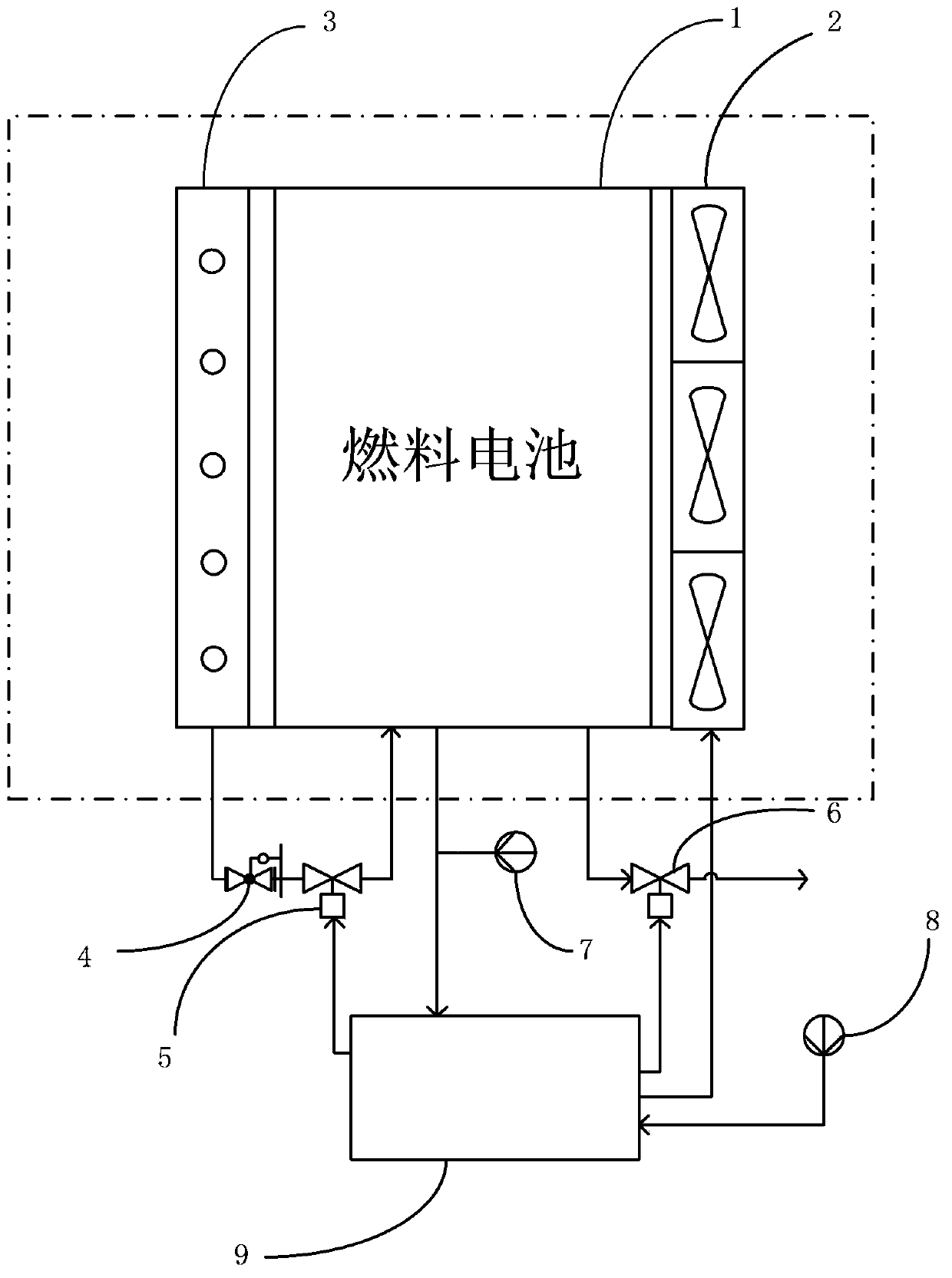

[0025] The air-cooled fuel cell system coupling thermal control method provided by the present invention can be achieved by figure 1 The fuel cell system shown is realized as figure 1The fuel cell system shown includes at least one fuel cell or fuel cell stack 1, at least one fuel cell fan 2, at least one hydrogen storage device or hydrogen storage stack 3, a fuel cell temperature sensor 7, an ambient temperature sensor 8, and a controller 9 And pressure reducing val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com