Catalyzed hydrogen desorption in mg-based hydrogen storage material and methods for production thereof

A technology of hydrogen storage material and magnesium-based hydrogen storage alloy, applied in the field of magnesium-based hydrogen storage materials, can solve the problems of impossible maintenance, short-range order not being preserved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

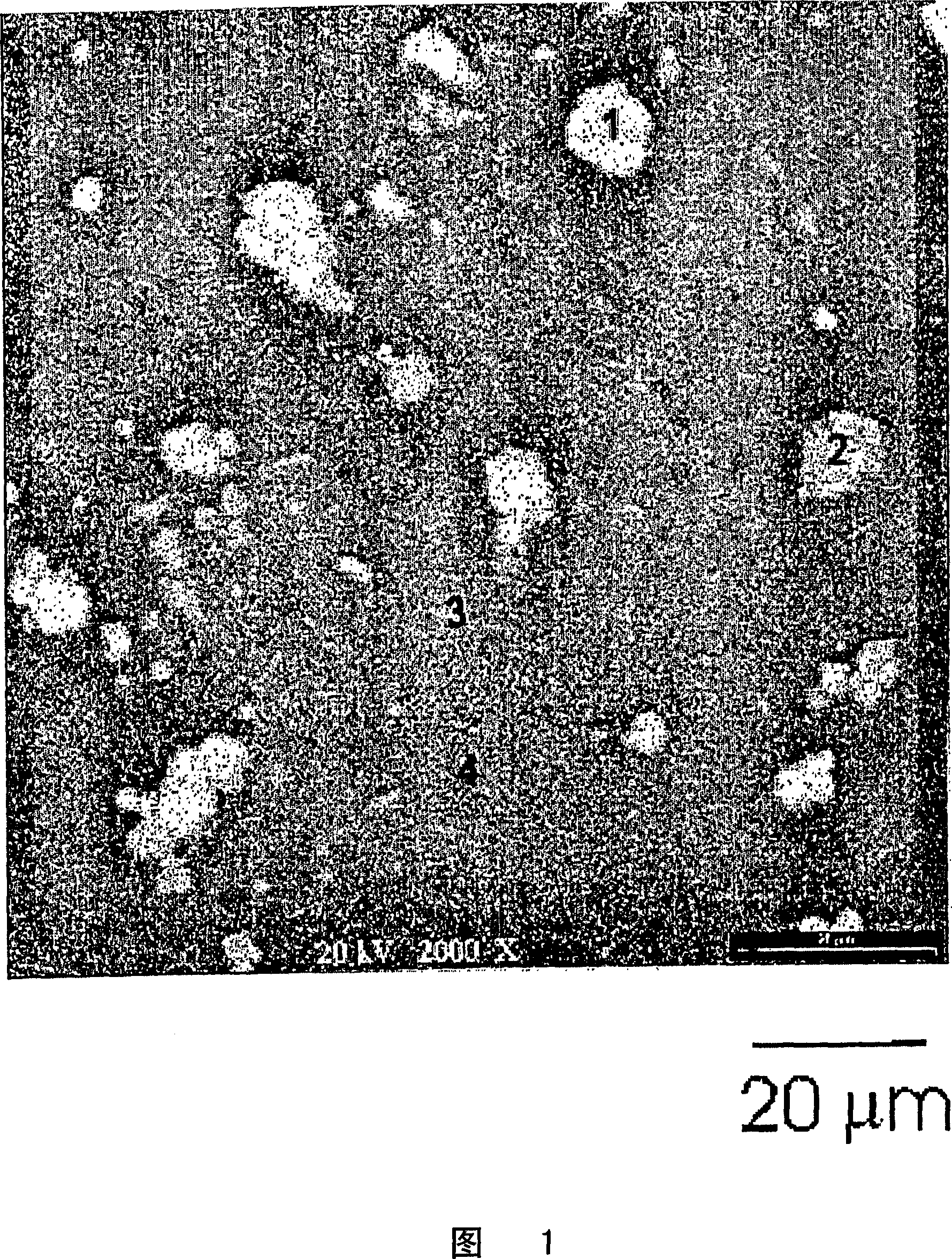

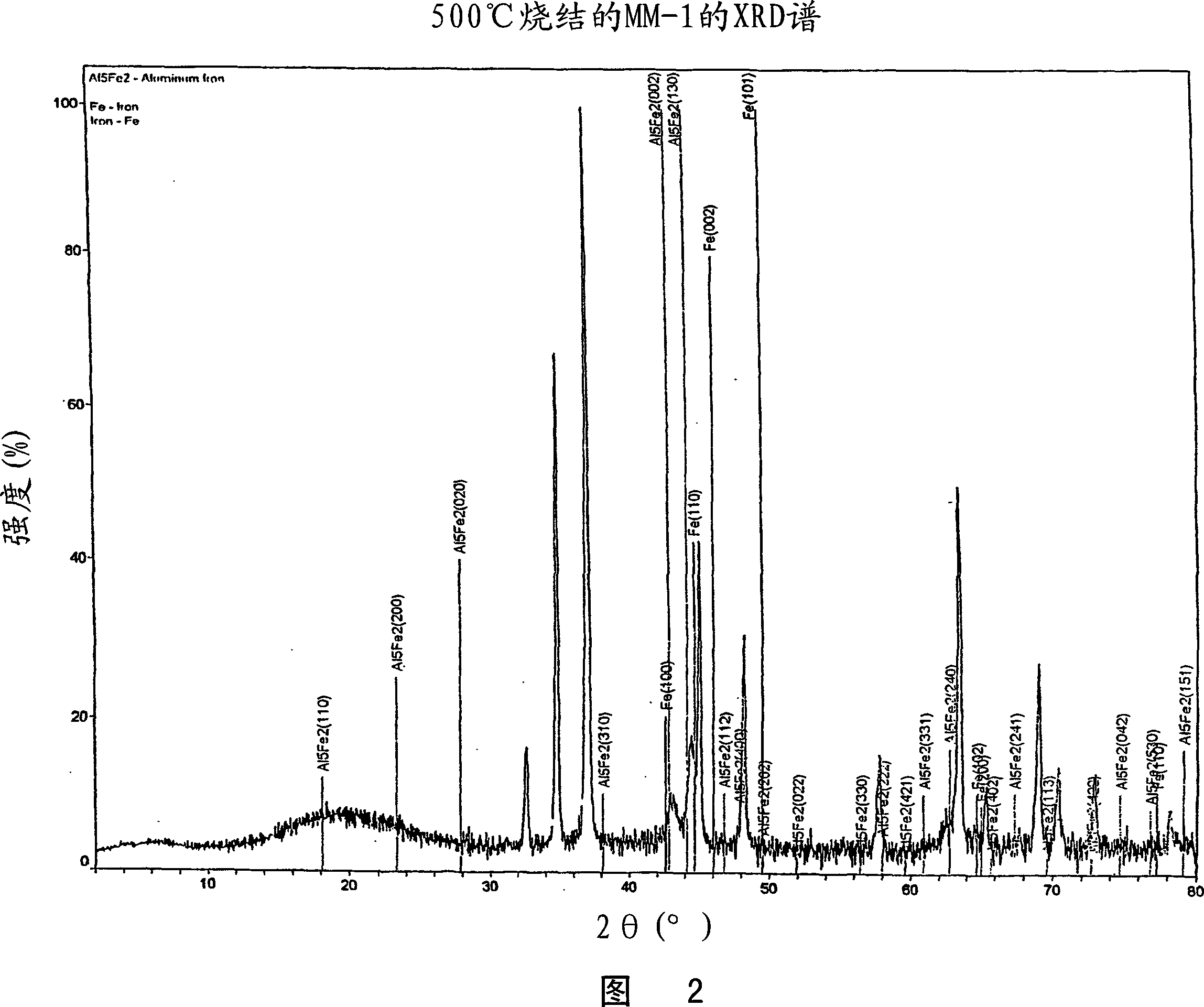

[0079] Raw materials consisting of pure metal powders magnesium (99.8%, 325 mesh), aluminum (99.5%, 325 mesh), iron (99.9+%, 10 microns) and other minor components were mixed in an agate mortar-pestle. Ten different compositions were prepared, and their weight percentage compositions are shown in Table 1. The mixed powders were pressed into pellets 1 cm in diameter and 1 cm in length using a hardened steel die. The pressed pellets were placed in a quartz tube and sintered under vacuum at a temperature above 500°C for 22 hours.

[0080] Table 1, chemical composition (all figures are percent by weight)

[0081] Alloy Number

Mg

Al

Fe

B

Cu

PD

V

Ni

C

sc

MM-1

88.8

2.7

8.5

-

-

-

-

-

-

-

MM-2

87

3

9

1

-

-

-

-

-

-

MM-3

86

3

9

2

-

-

-

...

Embodiment 2

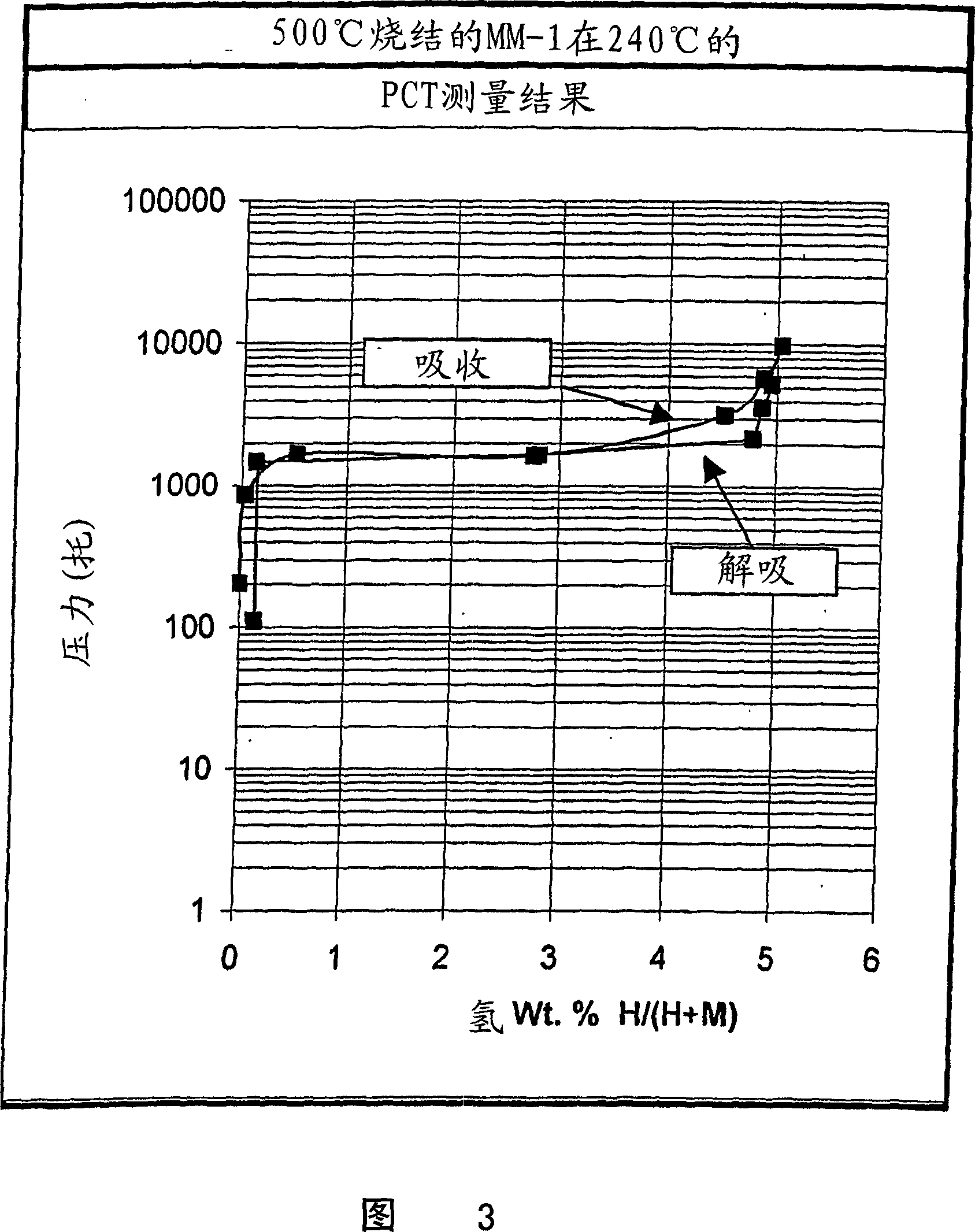

[0085] Another MM-1 material was prepared by changing the sintering / annealing temperature by the method of Example 1. Figure 6 shows the PCT curves of the samples sintered / annealed at 570°C and 600°C, respectively. While the PCT of the material sintered / annealed at 570°C (sintered / annealed at 500°C) and the PCT of the material of Example 1 showed little deviation, the material sintered / annealed at 600°C provided an extended plateau at slightly higher pressures .

Embodiment 3

[0087] Mechanically alloyed (MA) powders of MM-1 were prepared from a mixture of pure elemental magnesium (99.8%, 325 mesh), aluminum (99.5%, 325 mesh) and iron (99.9+%, 10 microns). Grinding was carried out in an attritor equipped with Cr-steel balls. The mechanical alloying process was carried out under an argon atmosphere with the addition of 1% graphite and heptane to prevent agglomeration of the material on the walls of the attritor. Usually the ball milling time is 2 hours. Figure 7 is a SEM backscattered micrograph of the sample. The figure shows severe phase segregation in the material. Area 1 (bright contrast on the photo) is filled with Fe and Al powders, while area 2 (the darker area in the center) is all magnesium. Figure 8 is the XRD pattern of the sample, showing that this process did not form any amorphous intermetallic products. MA-MM-1 powder was pressed onto an expanded nickel metal substrate, and then coated with 100 Å of iron on both sides as a surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com