Metal hydride hydrogen storage device

A hydrogen storage device and hydride technology, which is applied in fixed capacity gas storage tanks, gas/liquid distribution and storage, pressure vessels, etc., can solve uneven heat transfer, inability to obtain heat, uneven hydrogen release of hydrogen storage alloys, etc. problems, to achieve the effects of easy manufacturing and processing, improved hydrogen release performance, and increased heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the following embodiments.

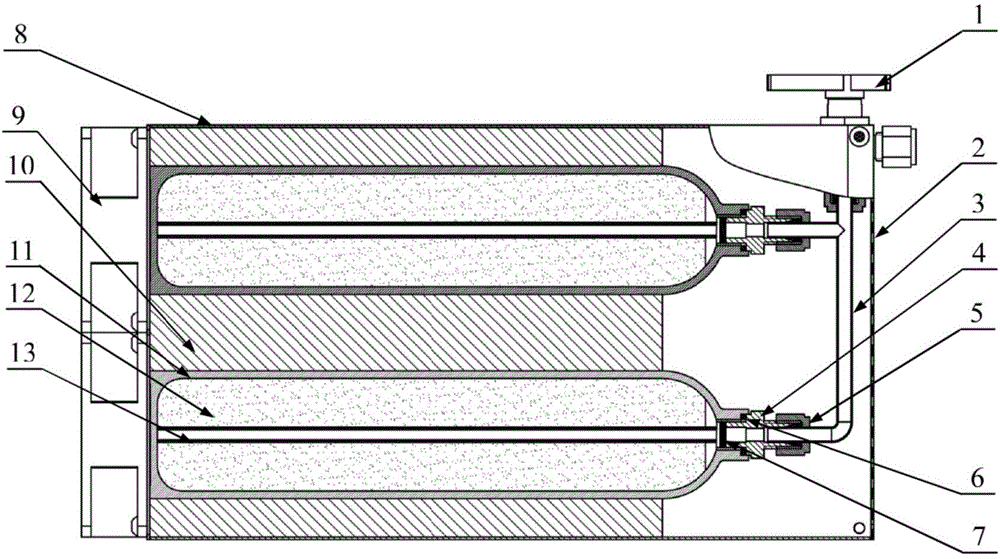

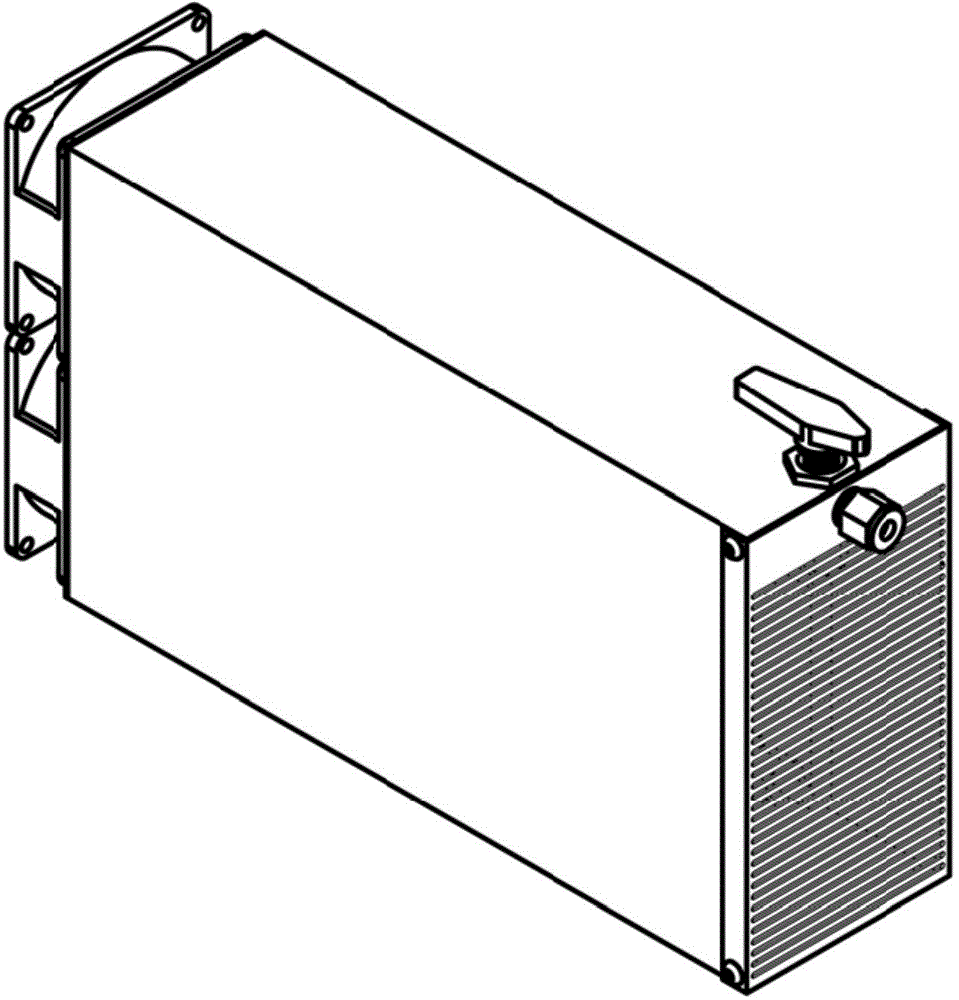

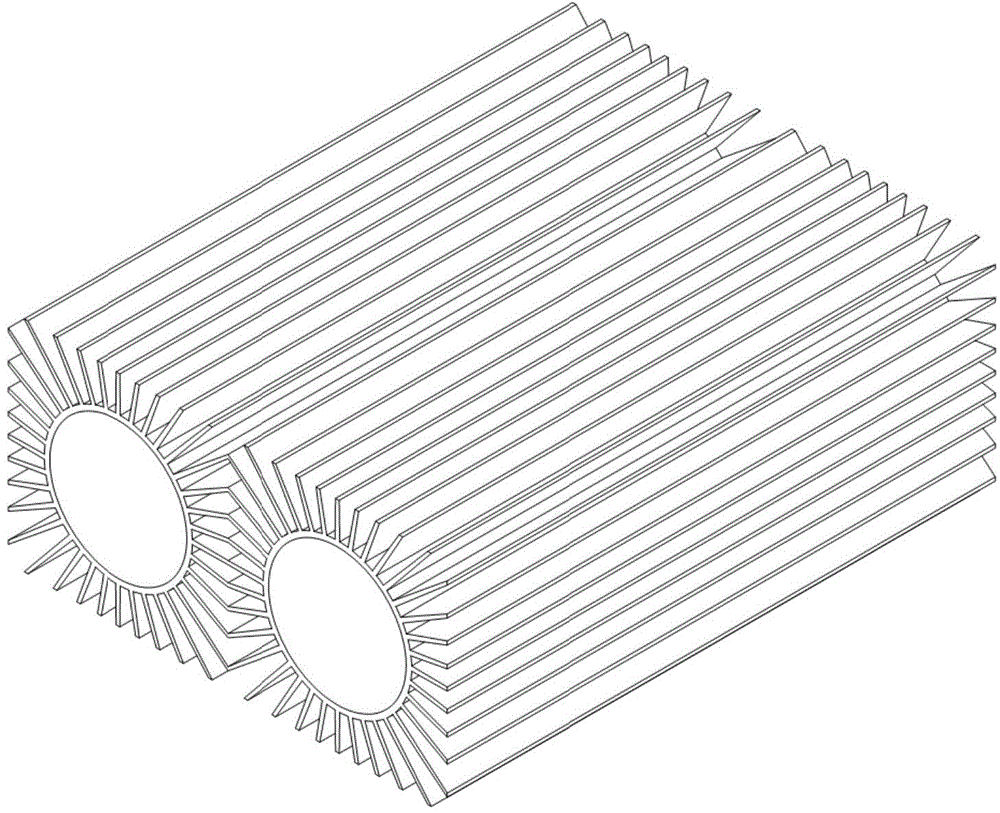

[0021] Such as figure 1 with figure 2 Shown are the structural schematic diagram (section view) and outline schematic diagram of the metal hydride hydrogen storage device provided by the present invention respectively. Gasket 6, filter sheet 7, shell 8, fan 9, longitudinal heat exchange finned tube 10, hydrogen storage bottle body 11, hydrogen storage material bed body 12, porous air duct 13;

[0022] One end of the bottle mouth joint 4 is connected and sealed with the hydrogen storage bottle body 11 through a sealing gasket 6, and the other end is connected with the gas pipe 3 through a ferrule 5; The valve 1 is connected; the front cover 2 is installed on the end of the shell 8 close to the valve 1, and two fans 9 are installed on the end away from the valve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com