Magnesium and multi-wall nano carbon tube composite hydrogen storage material and process for preparing same

A technology of multi-walled carbon nanotubes and hydrogen storage materials, which is applied in the direction of electrical components, circuits, battery pack components, etc., can solve the problem of high hydrogen depletion temperature, slow magnesium dehydrogenation speed, and composite hydrogen storage materials that have not achieved comprehensive integration Performance and other issues, to achieve the effect of reducing decomposition temperature, promoting rapid production, improving direct activation and hydrogenation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

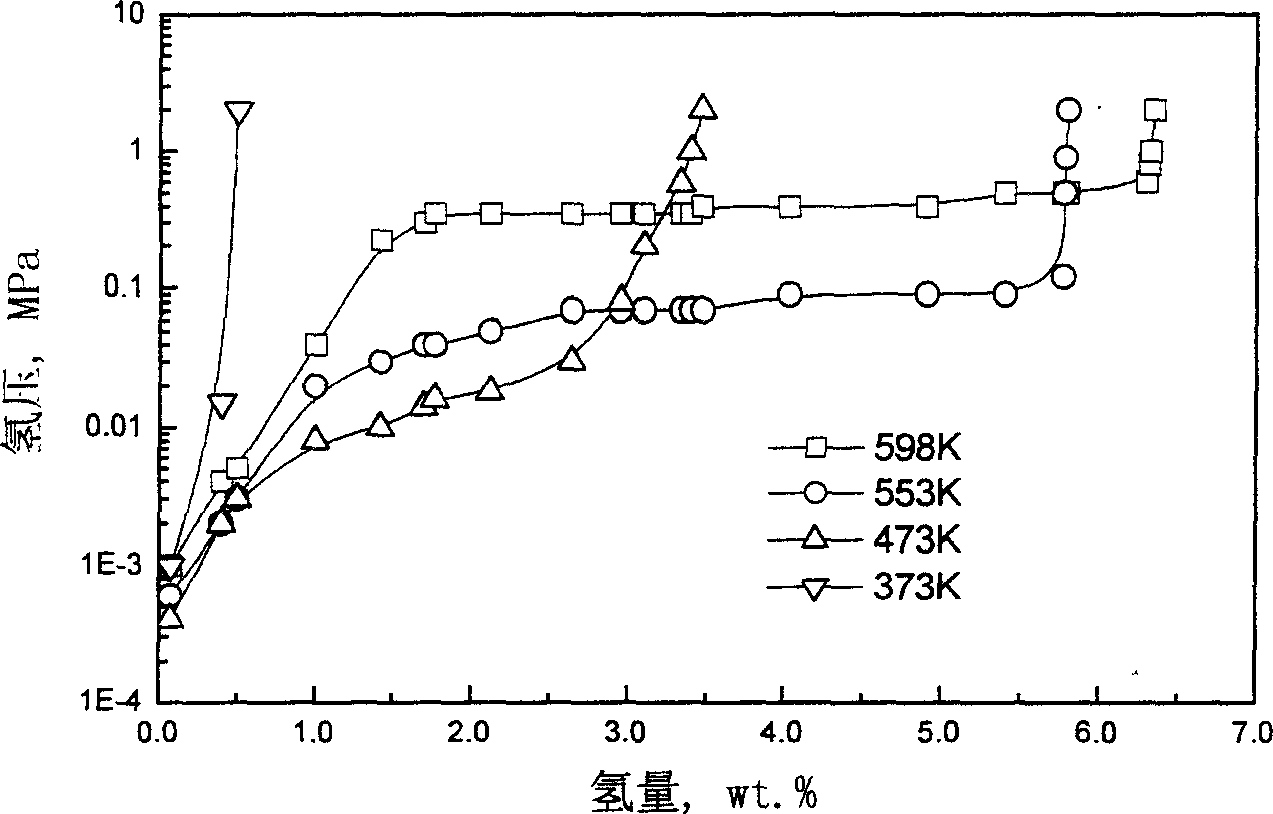

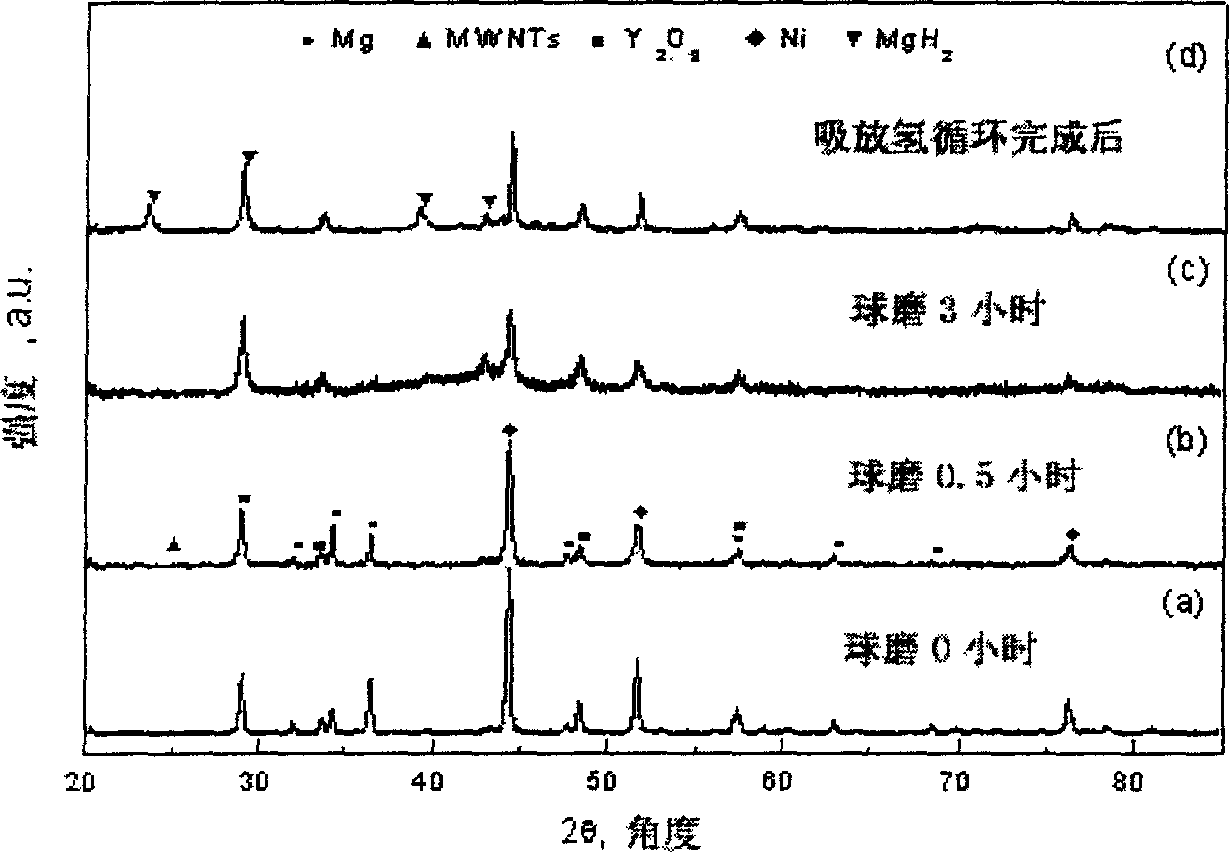

[0037] 200 mesh magnesium powder (purity is 98%) plus 5wt.% MWNTs (about 30nm outer diameter, multi-walled carbon nanotubes were used by the Advanced Carbon Materials Research Department of Shenyang Materials Science National (United) Laboratory, Institute of Metal Research, Chinese Academy of Sciences. Prepared and provided by catalytic pyrolysis) weighed according to a certain mass ratio to form (2.85 parts of Mg+0.15 parts of MWNTs) components, and then add 0.02 parts of Y 2 o 3 Ni powder (purity is 4N) and 0.10 parts of Ni powder (purity is 99.6%) are fully ground and mixed in an agate bowl, and then placed together with steel balls with a diameter of 6 to 12 mm and sealed in a ball mill jar. The ball-to-powder ratio is 20:1, after repeated vacuuming and hydrogen passing operations, filled with 0.1MPa high-purity hydrogen (purity 99.99%), and ball milled at room temperature for 5 hours to prepare Mg / 5wt.%MWNTs composite material. The hydrogen storage and release capacity ...

Embodiment 2

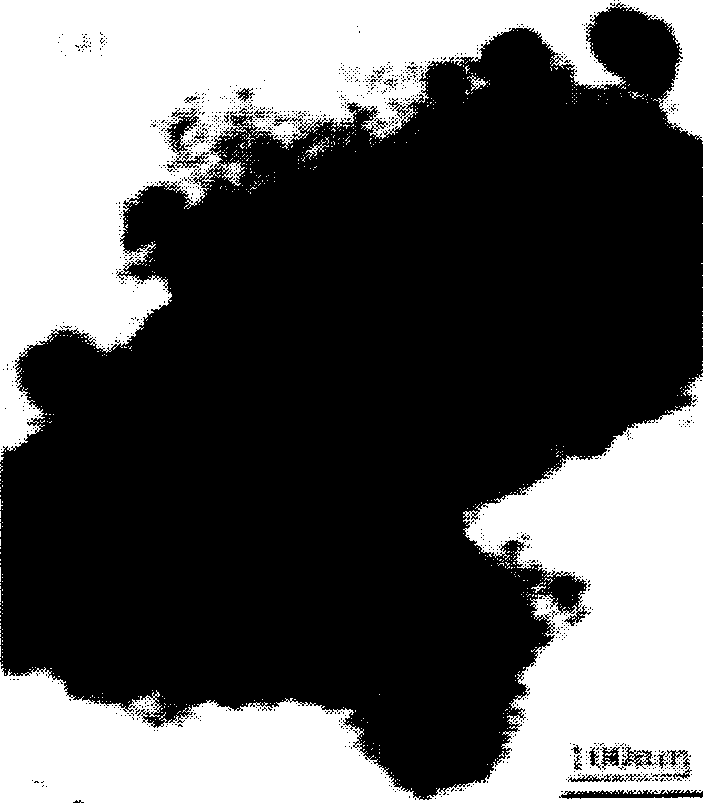

[0045] 150 mesh magnesium powder (purity 98%), 5wt.% MWNTs (about 50nm outer diameter) were weighed according to a certain mass ratio to form (2.85 parts of Mg+0.15 parts of MENTs) components, and then 0.01 parts of Zr powder (purity 98%) and 0.10 part of Ni powder (purity is 99.6%), ball powder ratio is 15: 1, is filled with 0.1MPa high-purity hydrogen (purity is 99.99%), ball milling 12 hours at normal temperature, according to embodiment 1 Mg / 5wt.%MWNTs composites were prepared by the same method. Figure 3 is the TEM morphology and SEAD diffraction pattern of the composite material. Figure 3(a) is the bright-field image of composite particles, showing that various samples are fully composited, dense and uniform. Figure 3(b) is the electron diffraction pattern related to Figure 3(a), where Mg, MgH 2 The diffraction rings are very obvious. Figure 3(c) and Figure 3(d) are the Mg and MgH in Figure 3(b), respectively 2 The corresponding dark-field images of the diffraction r...

Embodiment 3

[0048] Weigh 100 mesh magnesium powder (purity 98%) and MWNTs (outer diameter about 100nm) according to a certain mass ratio to form (2.40 parts Mg+0.60 parts MWNTs) component, then add 0.01 part Zr powder (purity 98% ) and 0.12 parts of Ni powder (purity is 99.6%), ball powder ratio is 10: 1, fills with 0.1MPa high-purity hydrogen (purity is 99.99%), ball milling time 30 hours at normal temperature, press the same method of embodiment 1 Preparation of Mg / 20wt.% MWNTs composites. Test by the test analysis method of embodiment 1.

[0049] The maximum hydrogen storage capacity of composite Mg / 20wt.% MWNTs is 0.90wt.%, 2.11wt.%, 2.68wt.% and 2.75wt. %. At the above-mentioned temperatures, 80% of the maximum hydrogen storage capacity is completed in 20, 15, 5 and 5 minutes respectively; the hydrogen absorption speed is roughly the same at 473K and 553K, slightly slower at 373K, and the slowest at 298K.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com