Method for preparing acetophenone by bionic catalytic oxidation of ethylbenzene

A technology for biomimetic catalysis of ethylbenzene and acetophenone, which is applied in the preparation of carbon-based compounds, chemical instruments and methods, and the preparation of organic compounds. It can solve the problems of low product selectivity and low conversion rate of raw materials, and achieve economical efficiency. Excellent, simple reaction operation, high selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

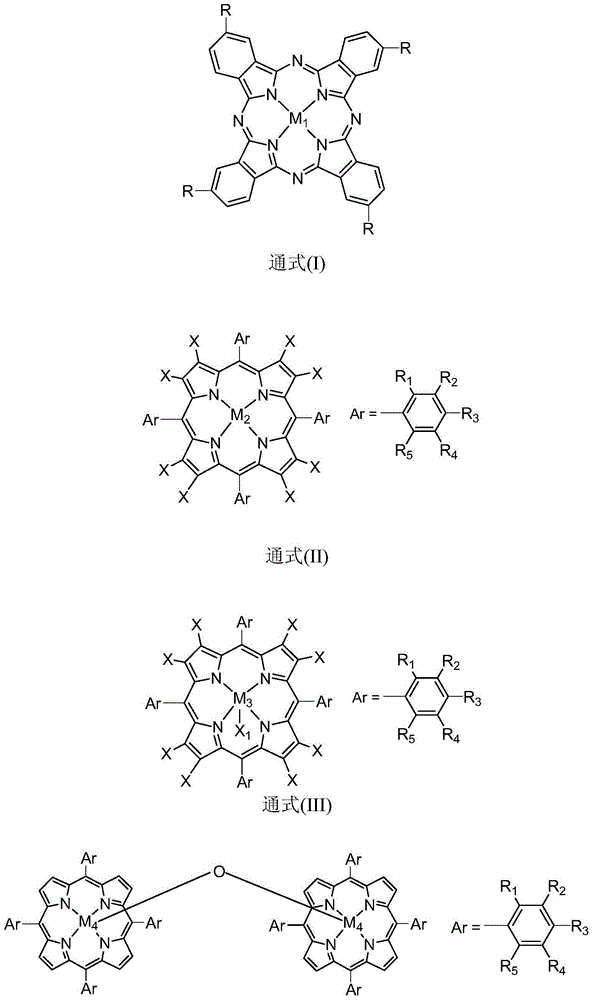

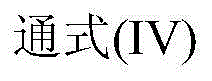

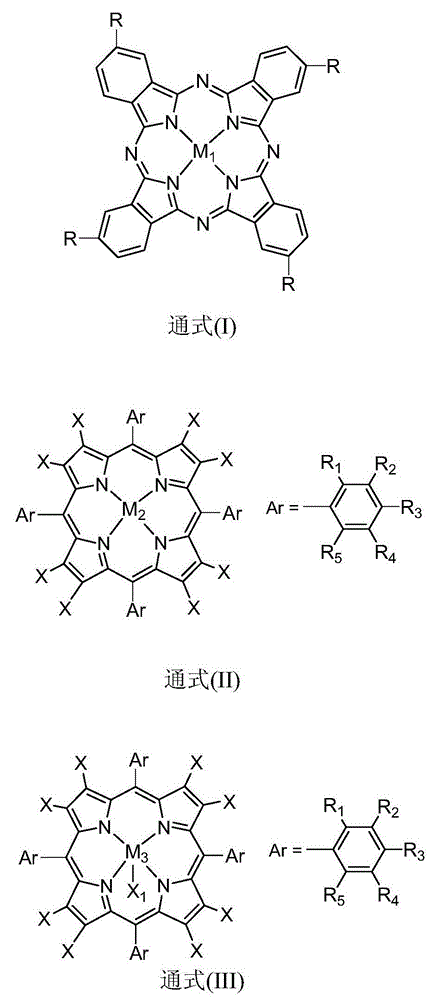

[0023] In the autoclave, add 10mL containing 1ppm and have general formula (I) structure metallophthalocyanine (M 1 =Fe, R=H) in toluene solution, add 8mmol of ethylbenzene and 8mmol of cyclohexene, fill with 0.2MPa of oxygen, stir and react at a temperature of 150°C, and detect by gas chromatography, the conversion rate of ethylbenzene is 34%, and the selectivity of acetophenone is 86%.

Embodiment 2

[0025] In the autoclave, add 10mL containing 100ppm and have general formula (I) structure metallophthalocyanine (M 1 =Cu, R=COOH) in dichloromethane solution, add 8mmol of ethylbenzene and 0.4mmol of 2-methylcyclohexene, fill with 3MPa of oxygen, stir the reaction at a temperature of 50°C, and perform gas chromatography Detection shows that the conversion rate of ethylbenzene is 24%, and the selectivity of acetophenone is 92%.

Embodiment 3

[0027] In the autoclave, add 10mL containing 500ppm and have general formula (II) structure metalloporphyrin (M 2 =Mn,X=H,R 2 =Cl,R 1 = R 3 = R 4 = R 5 =H) ethyl acetate solution, add 8mmol of ethylbenzene and 16mmol of 3-methylcyclohexene, fill with 2MPa of oxygen, stir and react at a temperature of 120°C, and detect through gas chromatography, ethylbenzene conversion The yield was 44%, and the selectivity of acetophenone was 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com