Hydrogen enriching exhaust recirculator for waste heat recovery of internal-combustion engine

A technology of exhaust gas recirculation and waste heat recovery, applied in exhaust devices, exhaust gas recirculation, internal combustion piston engines, etc., can solve the problem of reducing the power output characteristics of the engine, increasing the distance of the exhaust valve port of the reactor, and unstable engine power output. and other problems, to achieve the effect of compact structure, easy installation in real vehicles, and fast reaction speed of hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

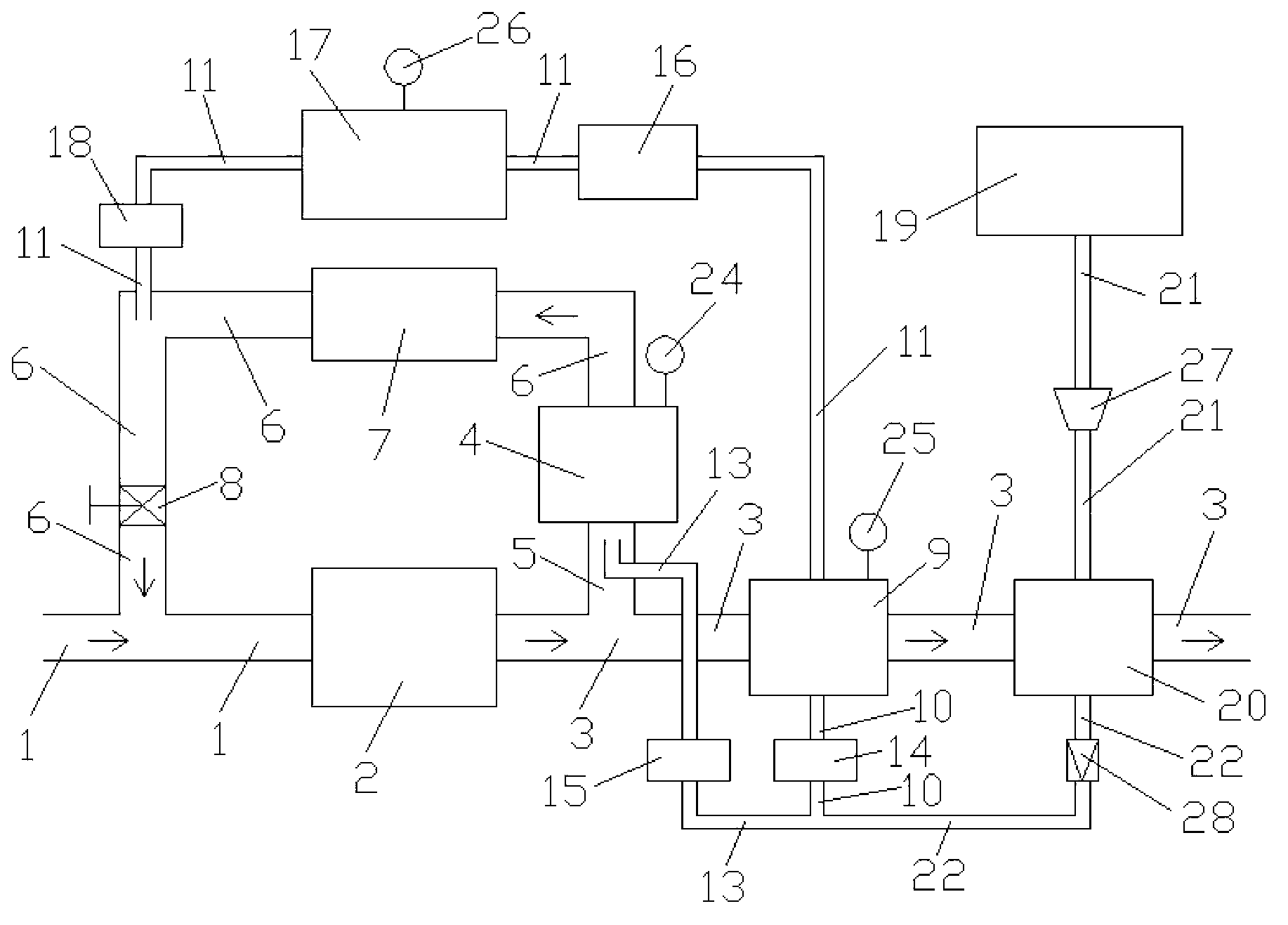

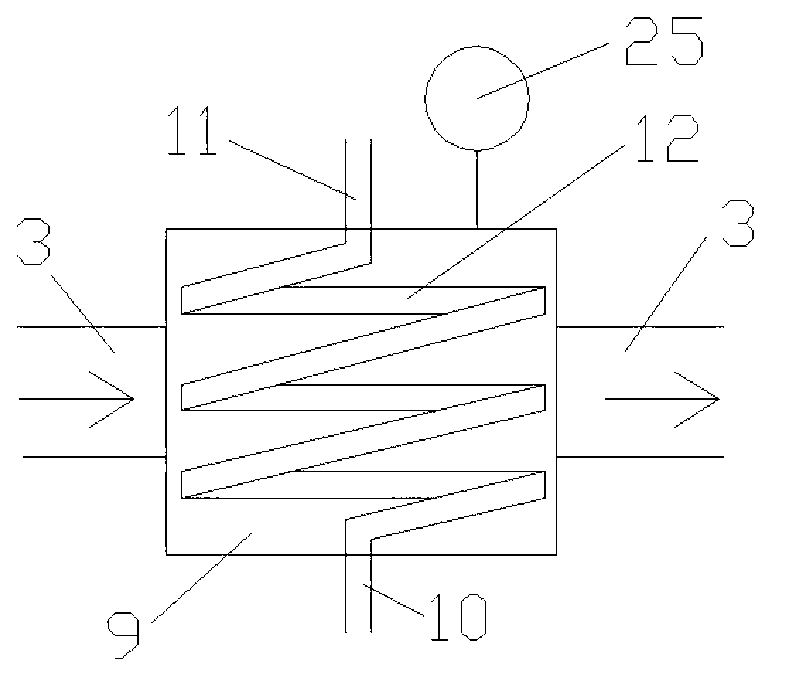

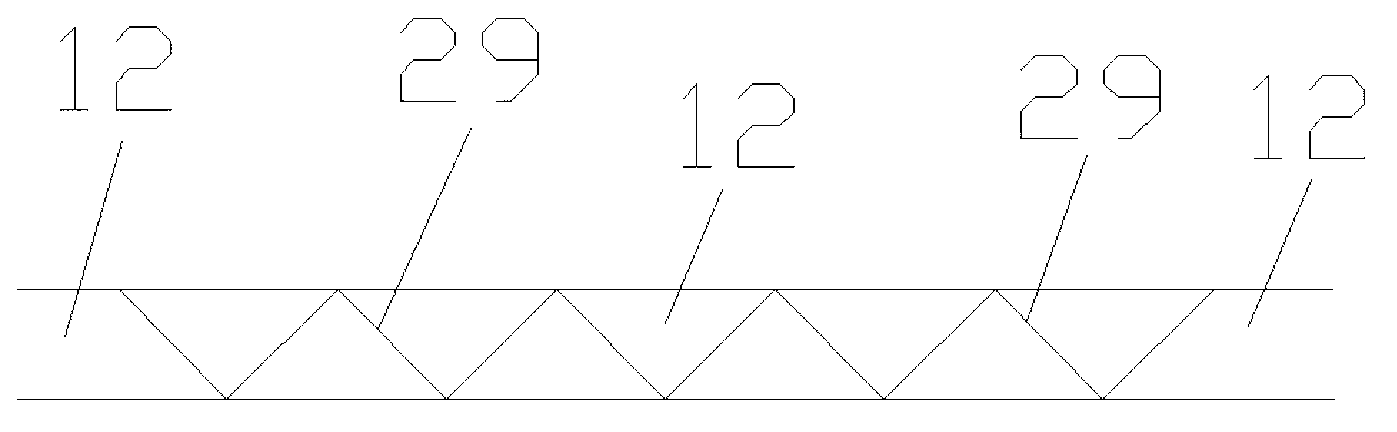

[0033] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention includes intake pipe 1, engine 2, engine exhaust pipe 3, first hydrogen generator 4, exhaust gas recirculation intake pipe 5, first hydrogen generator outlet pipe 6, exhaust gas recirculation cooler 7 , Exhaust gas recirculation control valve 8, second hydrogen generator 9, second hydrogen generator inlet pipe 10, second hydrogen generator outlet pipe 11, second heat exchange pipe 12, first hydrogen generator inlet pipe 13, Second mass flow controller 14, first mass flow controller 15, supercharger 16, hydrogen-rich gas buffer tank 17, third mass flow controller 18, hydrogen energy carrier storage tank 19, evaporator 20, evaporator flow Inlet pipe 21, evaporator outflow pipe 22, first heat exchange pipe 23, first temperature sensor 24, second temperature sensor 25, pressure sensor 26, liquid pump 27, check valve 28 and wire 29, the inlet and outlet of engine 2 The air ports are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com