Method for efficiently enriching gold and platinum group metals from complex low-grade rhodium iridium residues

A platinum group metal, low-grade technology, applied in the direction of process efficiency improvement, etc., can solve the problems of poor separation process, permanent loss, dispersion loss of precious metals, etc., to achieve simple separation and refining process, eliminate fine and sticky, and eliminate adverse effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

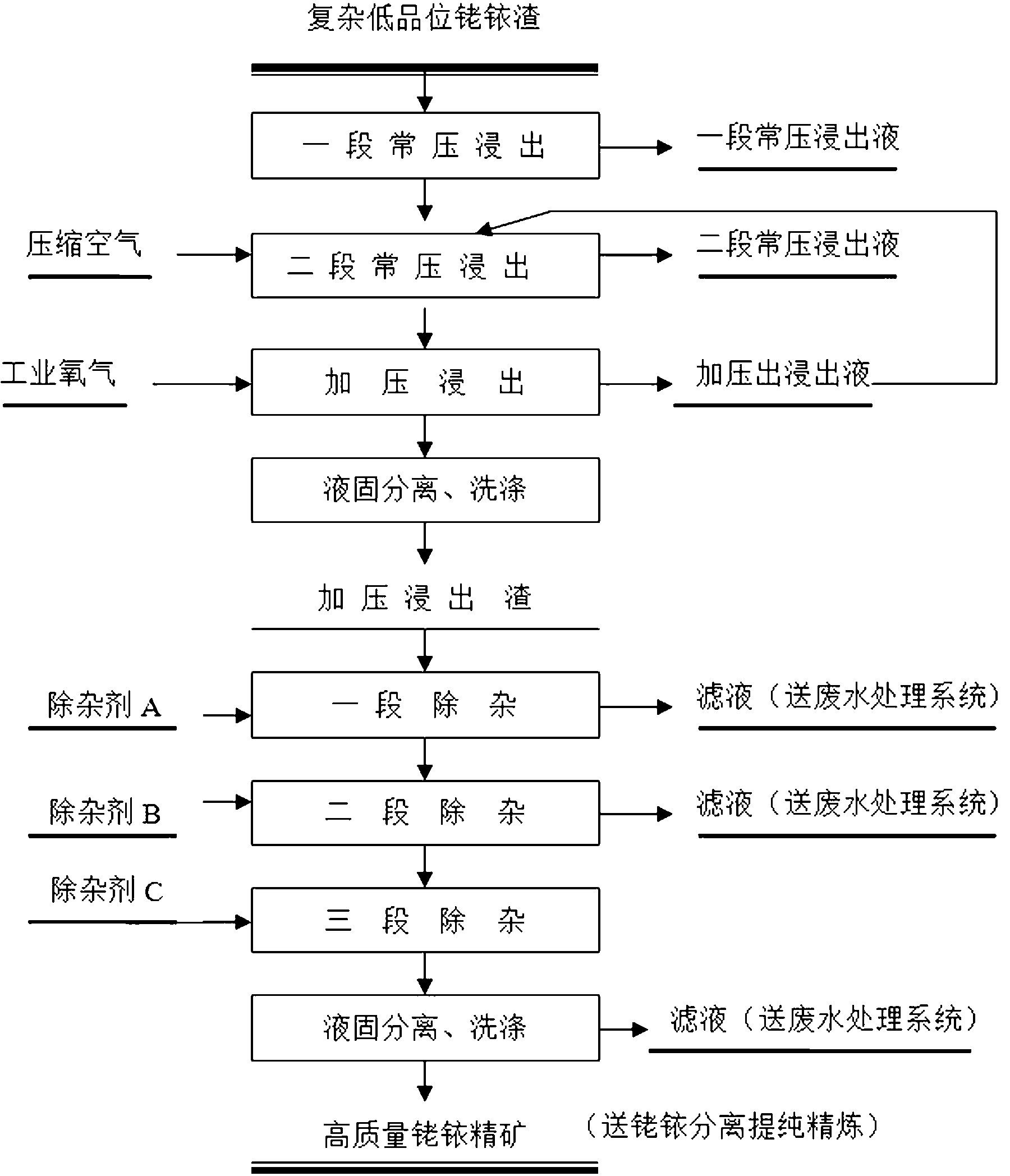

Method used

Image

Examples

Embodiment 1

[0030] Complicated low-grade rhodium-iridium slag 400g (dry weight) for small-scale experiments, its chemical composition is Ni4.42%, Cu19.52%, Fe0.87%, Co0.45%, Pb9.7%, Zn9.33%, Mg1 .87%, Sb1.33%, As2.33%, S6.53%, Se1.53%, Te0.13%, SiO 2 3.20%, Au0.066%, Pd0.148%, Pt0.309%, Rh0.318%, Ir0.806%, Ru179g / t;

[0031] According to the above method, a section of normal pressure leaching solution was obtained, and its chemical composition was: Au0.0002g / L, Pd not detected, Pt not detected, Rh not detected, iridium not detected, base metal leaching rate nickel 61.2%, The zinc leaching rate is 68.46%, the magnesium leaching rate is 86.3%, and the non-metallic chloride ion leaching rate is 99.6%;

[0032] The chemical composition of the second-stage atmospheric pressure leaching solution is: Au not detected, Pd0.0015g / L, Pt0.00020g / L, Rh0.00020g / L, iridium 0.00020g / L, base metal leaching rate nickel 90.2%, zinc leaching The extraction rate is 73.02%, the magnesium leaching rate is 96....

Embodiment 2

[0041] 40 kg of complex low-grade rhodium-iridium slag, carried out enlarged test, its chemical composition is Ni3.95%, Cu19.77%, Fe0.77%, Co0.40%, Pb10.7%, Zn10.33%, Mg1.97 %, Sb1.25%, As2.28%, S8.32%, Se1.67%, Te0.19%, SiO 2 2.99%, Au0.041%, Pd0.462%, Pt0.236%, Rh0.386%, Ir0.785%, Ru523g / t;

[0042] According to the above method, a section of atmospheric pressure leaching solution was obtained, and its chemical composition was: Au was not detected, Pd0.0002g / L, Pt was not detected, Rh was not detected, iridium was 0.0002g / L, and the leaching rate of base metal nickel was 60.8%. , The zinc leaching rate is 70.14%, the magnesium leaching rate is 87.6%, and the non-metallic chloride ion leaching rate is 99.3%;

[0043] The chemical composition of the second-stage atmospheric pressure leaching solution is: Au not detected, Pd0.0019g / L, Pt not detected, Rh0.00020g / L, iridium 0.0005g / L, base metal leaching rate nickel 90.7%, zinc leaching rate 72.89%, magnesium leaching rate 96....

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com