Composite solid electrolyte and preparation method thereof

A solid electrolyte and electrolyte technology, which is applied in the field of lithium-ion batteries, can solve the problems of low electrical conductivity and poor mechanical properties of solid electrolytes, and achieve the effects of low cost, low toxicity, and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] 1. A method for preparing a composite solid electrolyte, comprising the steps of:

[0061] (1) Synthesis of polydichlorophosphazene: react 5 g of hexachlorocyclotriphosphazene at 220° C. for 10 h to obtain polydichlorophosphazene;

[0062] (2) Dissolving the polydichlorophosphazene in step (1) in tetrahydrofuran, adding 3 g of sodium ethylate, and reacting at 60° C. for 10 h to obtain polyphosphazene;

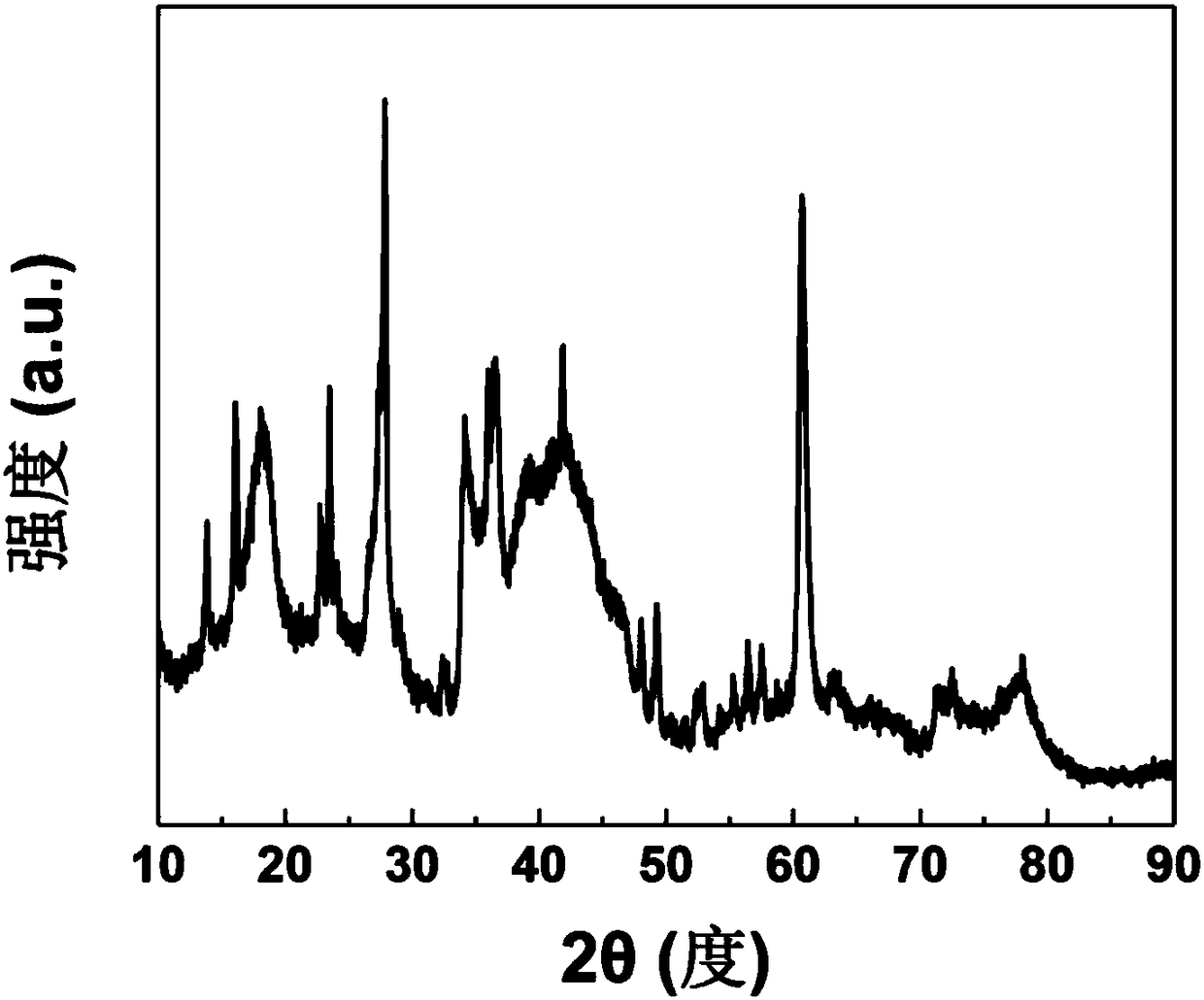

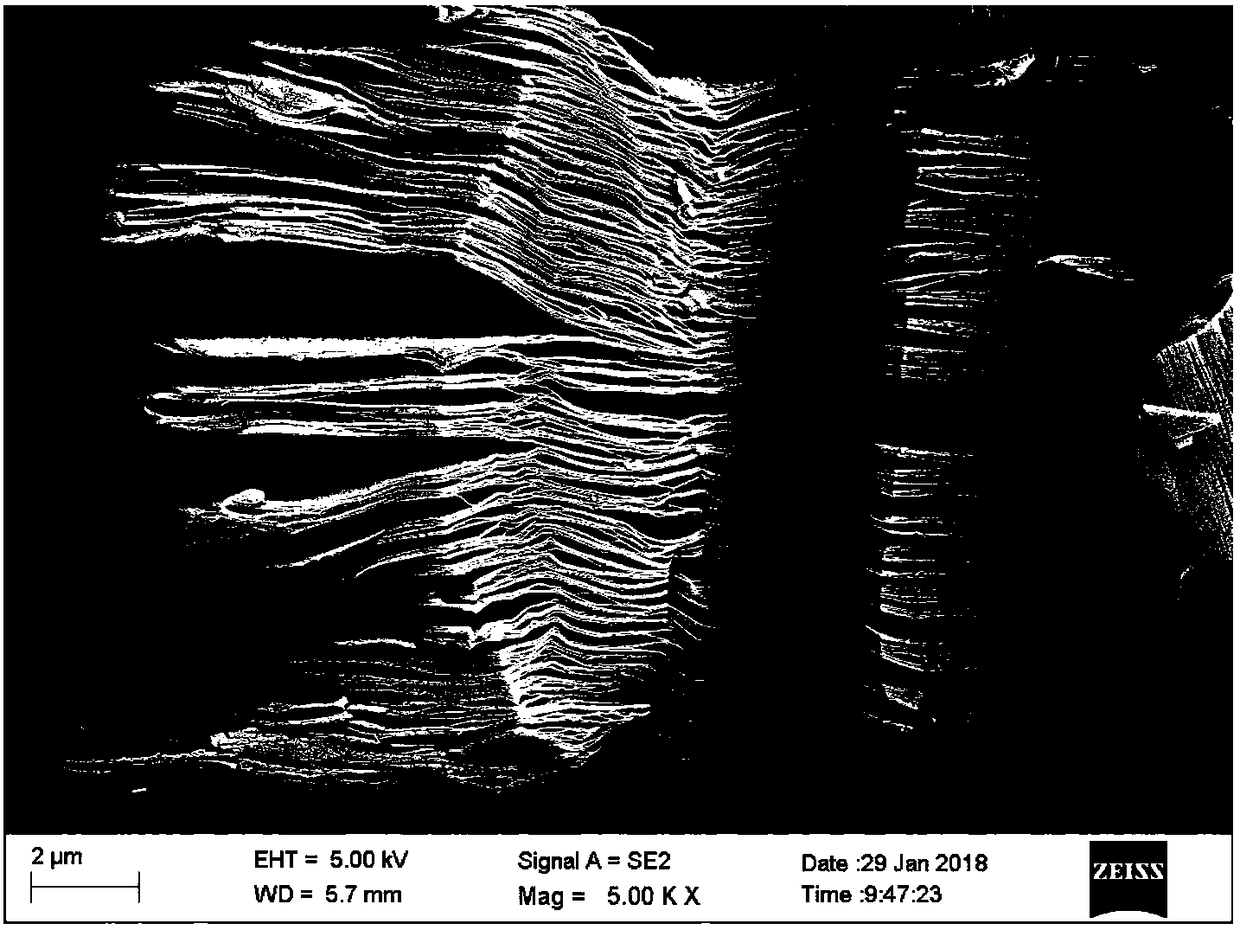

[0063] (3) 0.2g polyphosphazene, 0.1gLLZO, 0.01gTi 3 C 2 1. Dissolve 0.05g LiTFSI in acetonitrile, react at room temperature for 5 hours, volatilize acetonitrile at room temperature, and then transfer to a vacuum drying oven to dry at 60°C for 16 hours to obtain a composite solid electrolyte.

[0064] 2. A composite solid electrolyte. In the composite solid electrolyte prepared in this example, the components polyphosphazene, LLZO, Ti 3 C 2 , The weight percentage of LiTFSI is: 20:10:1:5.

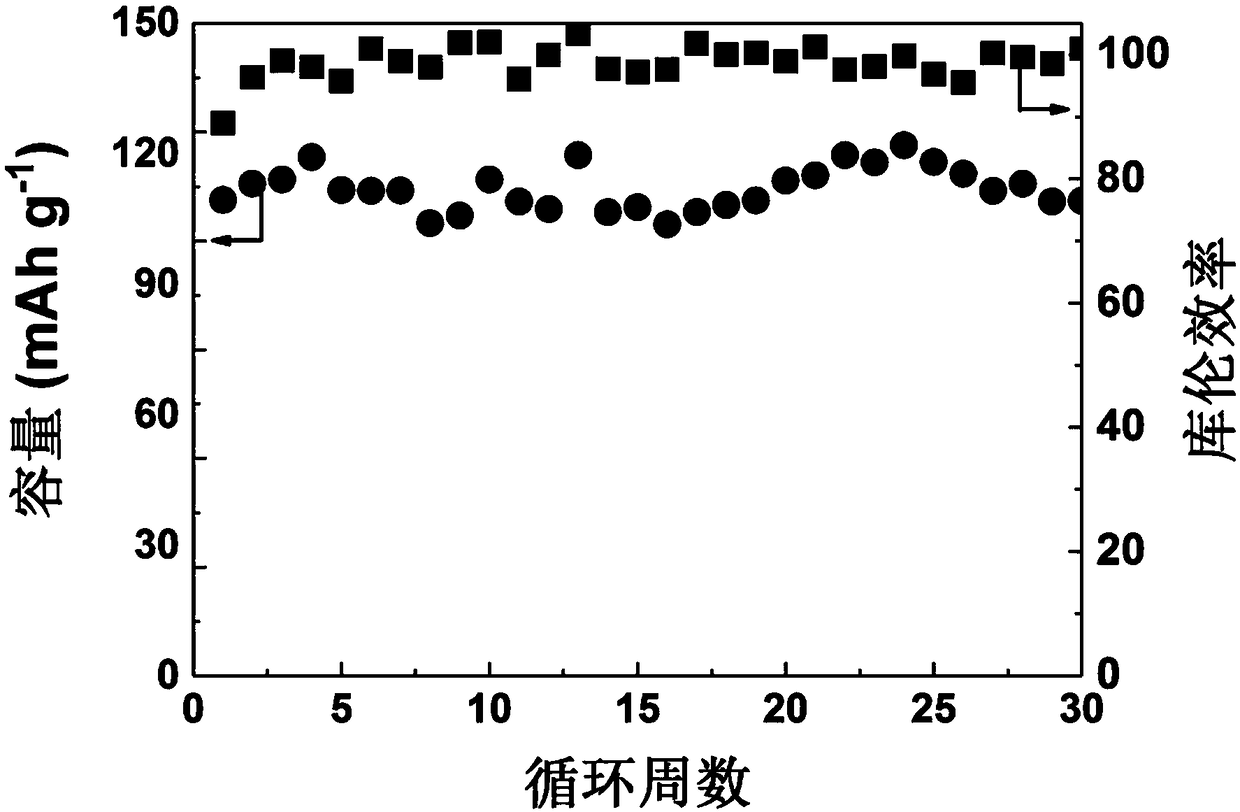

[0065] 3. An all-solid-state lithium battery. The composite solid-state elec...

Embodiment 2

[0067] 1. A method for preparing a composite solid electrolyte, comprising the steps of:

[0068] (1) Synthesis of polydichlorophosphazene: react 5 g of hexachlorocyclotriphosphazene at 230°C for 5 hours to obtain polydichlorophosphazene;

[0069] (2) Dissolving the polydichlorophosphazene in step (1) in tetrahydrofuran, adding 3 g of sodium ethoxide, and reacting at 70° C. for 8 hours to obtain polyphosphazene;

[0070] (3) Add 0.2g polyphosphazene, 0.08g LLTO, 0.01g VC, 0.05g LiPF 6 Add acetone, react for 5 hours, volatilize acetonitrile at room temperature, and then transfer to a vacuum oven to dry at 60°C for 12 hours to obtain a composite solid electrolyte.

[0071] 2. A composite solid electrolyte. In the composite solid electrolyte prepared in this example, the components polyphosphazene, LLZO, Ti 3 C 2 , The weight percentage of LiTFSI is: 20:8:1:5.

[0072] 3. An all-solid-state lithium battery. The composite solid-state electrolyte obtained in this embodiment is ...

Embodiment 3

[0074] 1. A method for preparing a composite solid electrolyte, comprising the steps of:

[0075] (1) Synthesis of polydichlorophosphazene: react 5 g of hexachlorocyclotriphosphazene at 200° C. for 20 h to obtain polydichlorophosphazene;

[0076] (2) Dissolving the polydichlorophosphazene in step (1) in tetrahydrofuran, adding 1.5 g of sodium ethoxide and 1.5 g of lithium ethoxide, and reacting at 60° C. for 10 h to obtain polyphosphazene;

[0077] (3) 0.15g polyphosphazene, 0.05g LPS, 0.03g Ti 2 C, 0.08g LiN(CF 3 SO 2 ) 2 Add it into acetonitrile, react for 5 hours, volatilize the acetonitrile at room temperature, and then transfer to a vacuum oven to dry at 80°C for 10 hours to obtain a composite solid electrolyte.

[0078] 2. A composite solid electrolyte. In the composite solid electrolyte prepared in this example, the components polyphosphazene, LLZO, Ti 3 C 2 , The weight percentage of LiTFSI is: 15:5:3:8.

[0079] 3. An all-solid-state lithium battery. The compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com