Wide temperature range and high extreme pressure composite lithium lubricating grease composition

A lubricating grease and lithium-composite technology, which is applied in lubricating compositions, petroleum industry, additives, etc., can solve the problems of high dropping point, low-temperature and extreme-pressure properties of lubricating grease, and cannot meet the requirements of lubricating grease. and other problems, to achieve the effect of excellent high and low temperature performance, excellent extreme pressure and anti-wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0035] Add 300g of base oil into a small test kettle, heat up to 85°C, add 60g of dodecyl hydroxystearic acid and 16g of sebacic acid, then add 16g of lithium hydroxide dissolved in 80g of water, heat up to 105-115°C for reaction 2h. Then raise the temperature for dehydration, raise the temperature to 130-140 and keep the temperature for 0.5h, continue to raise the temperature, add 4.2g of diisooctyldiphenylamine, the highest temperature is 208°C. Add 160g of base oil to lower the temperature. When the temperature drops below 150°C, add the remaining 304g of base oil. When the temperature is lower than 90°C, add 8.4g of barium petroleum sulfonate, 4.2g of thiadiazole derivatives, and 42g of dialkyl dithio Carbamate, 25.2 g phosphorothioate, 4.2 g zinc dialkyldithiophosphate. Finally, grind and homogenize on three-axis rollers, and measure the grease performance.

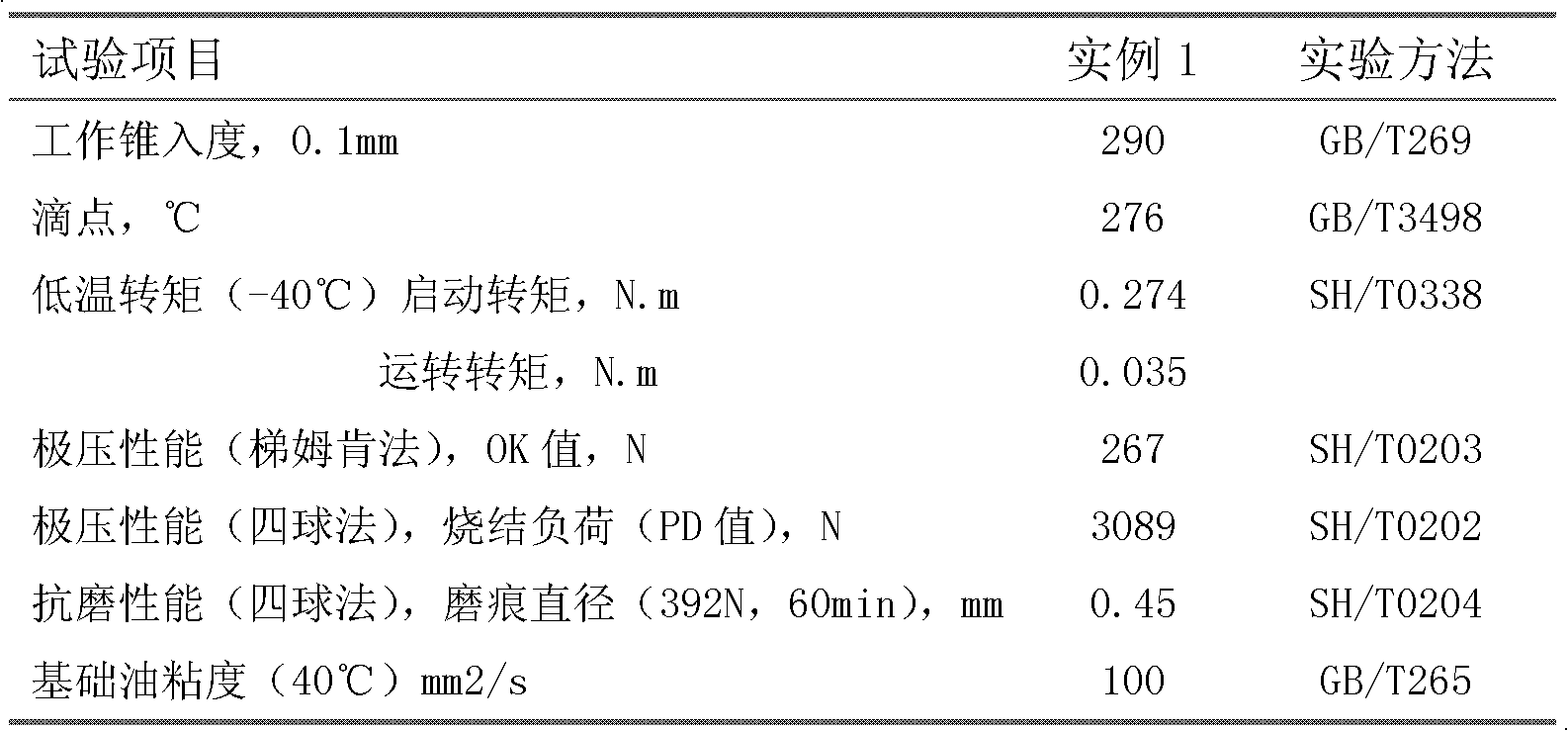

[0036] The performance of the lubricating grease that process formula of the present invention makes is listed i...

example 2

[0040] Add 450g of base oil into a small test kettle, heat up to 85°C, add 80g of lauryl hydroxystearic acid and 40g of azelaic acid, then add 30g of lithium hydroxide dissolved in 110g of water, heat up to 100-110°C for reaction 2.5h. Then heat up for dehydration, heat up to 125-135°C for 45 minutes, continue to heat up, add 8g of diisooctyldiphenylamine and 8g of tert-butylphenol derivatives, and the maximum temperature is 200°C. Add 150g of base oil to cool down. When the temperature drops below 150°C, add the remaining 80g of base oil and 0.4g of benzotriazole. When the temperature is lower than 90°C, add 4g of dialkyl dithiocarbamate, 9.6 g phosphorothioate, 24 g zinc dialkyldithiophosphate, 8 g borate. Finally, grind and homogenize on three-axis rollers, and measure the grease performance.

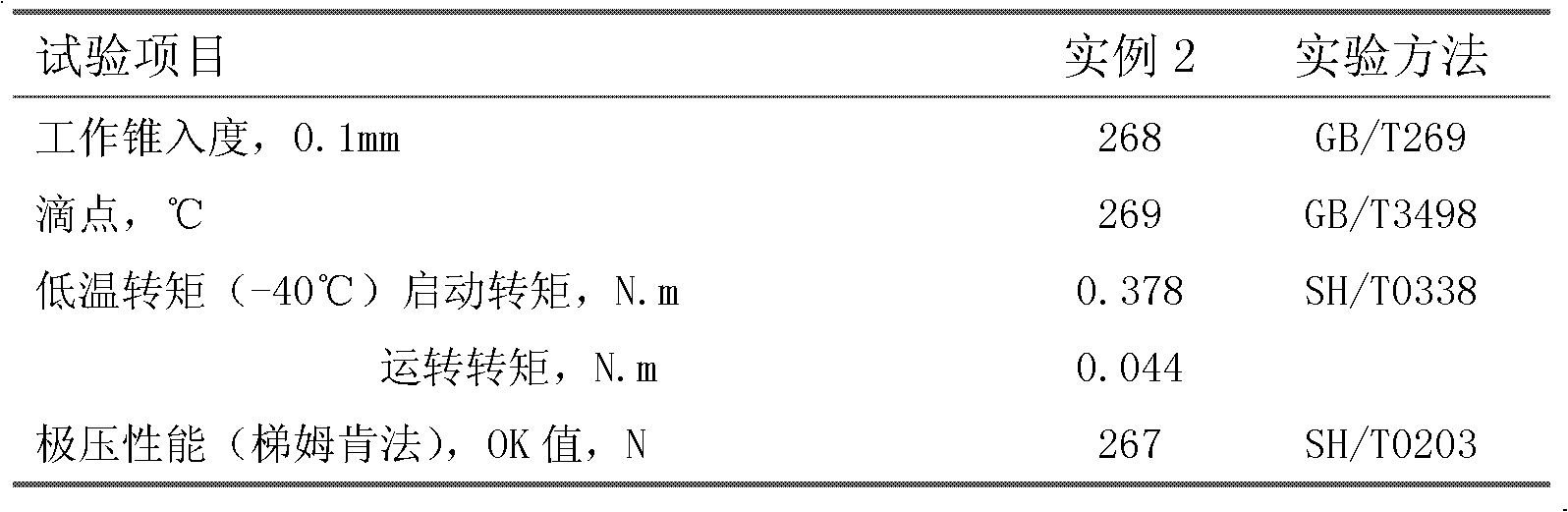

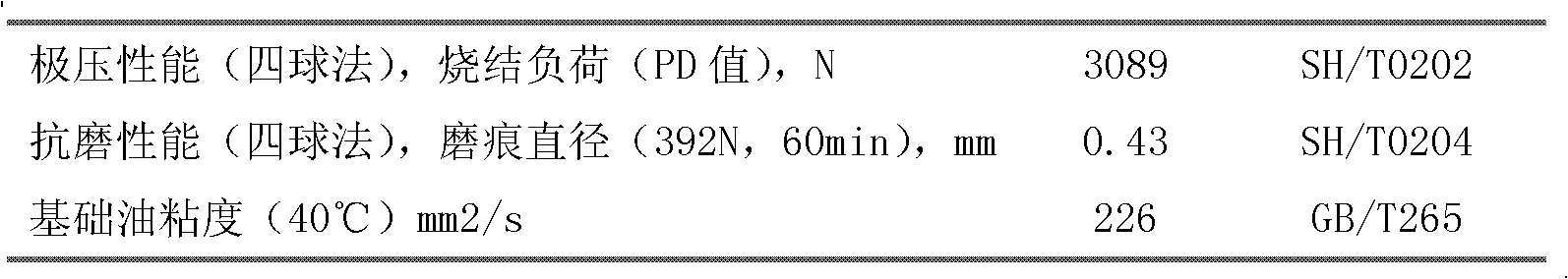

[0041] The performance of the lubricating grease that process formula of the present invention makes is listed in table 2

[0042] Table 2

[0043]

[0044]

example 3

[0046] 300g of poly-α-olefin synthetic oil is added in the small test kettle, the temperature is raised to 85°C, 60g of dodecyl hydroxystearic acid and 35g of dodecanedibasic acid are added, and then 21g of lithium hydroxide dissolved in 120g of water is added, Raise the temperature to 105-115°C for 3 hours. Then raise the temperature for dehydration, raise the temperature to 130-140°C for 1 hour, continue to raise the temperature, add 6g of diisooctyldiphenylamine, and the maximum temperature is 220°C. Add 235g of base oil to cool down. When the temperature drops below 150°C, add the remaining 220g of base oil and 0.8g of benzotriazole. When the temperature is lower than 90°C, add 17g of dialkyl dithiocarbamate, 4.25 g phosphorothioate, 25.5 g borate. Finally, grind and homogenize on three-axis rollers, and measure the grease performance.

[0047] The performance of the lubricating grease that process formula of the present invention makes is listed in table 3

[0048] tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com