Low-noise bearing lubricating grease and preparation method thereof

A bearing lubrication and low noise technology, applied in the field of lubrication, can solve health hazards and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with specific embodiments.

[0012] The lubricating grease composition is composed by weight percentage: 5-10% of C12-C24 hydroxy fatty acid; 2-4% of lithium hydroxide; 20%-30% of naphthenic mineral oil, and 50%-60% of ester synthetic oil The base oil is made by mixing naphthenic mineral oil and ester synthetic oil; additives include organic amine antioxidant 0.5-1.5%, anti-corrosion and anti-rust agent 0.5-2.0%, anti-wear extreme pressure agent 2-6%.

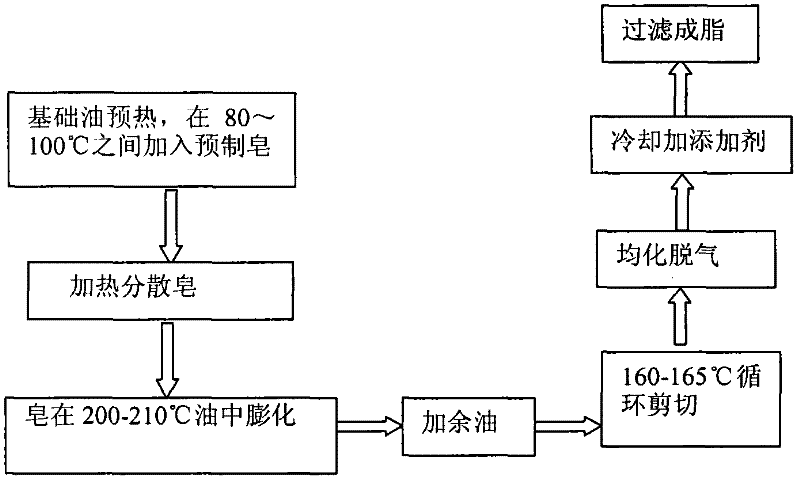

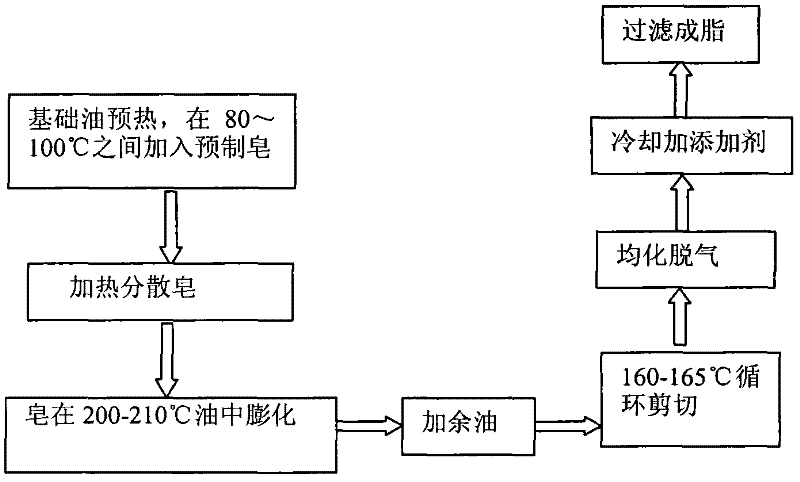

[0013] Grease preparation process figure 1 shown. The preparation method of the lubricating grease composition firstly carries out the saponification reaction of the measured C12-C24 hydroxyl fatty acid and lithium hydroxide, dehydrates and dries the generated fatty acid lithium, and grinds it into prefabricated soap powder; it will account for 2 / 3 of the total amount Preheat the base oil mixed with naphthenic mineral oil and ester synthetic oil, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com