Lubricating grease composition

A technology of lubricating grease composition and synthetic oil, which is applied in the direction of lubricating composition and petroleum industry, etc., can solve the problems such as the deterioration of bearing torque performance, and achieve the effect of excellent acoustic performance and long service life of bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

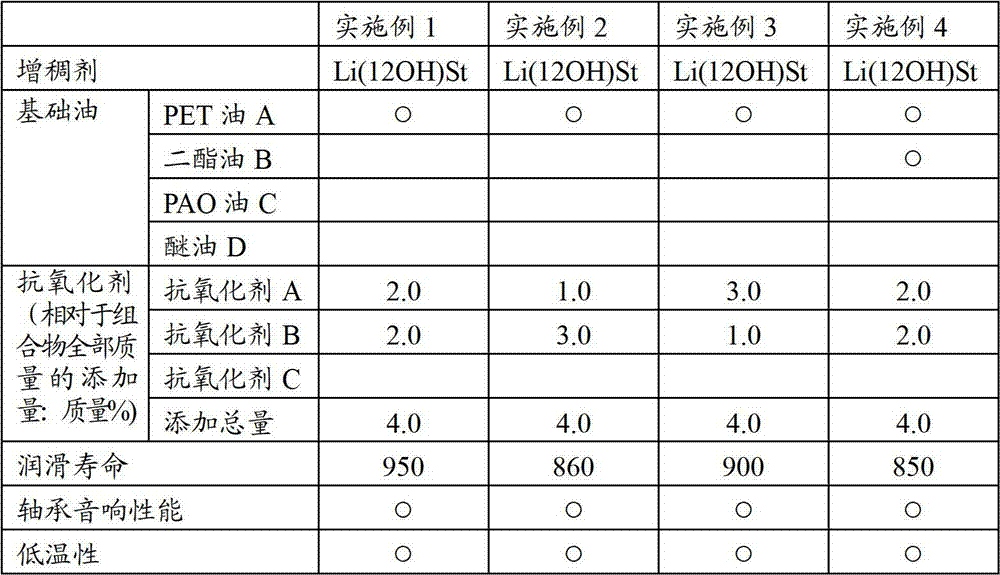

[0066] Test grease

[0067] ·Examples 1 to 4 and Comparative Examples 1 to 6

[0068] Mix lithium 12-hydroxystearate in the base oil shown below, heat and dissolve, and cool to make a basic grease. A predetermined amount of antioxidant is mixed with base oil, added to the basic grease, mixed thoroughly, and kneaded using a three-roll mill to produce a grease composition with a mixed consistency of 250 (JIS K2220).

Embodiment 4

[0076] The kinematic viscosity at 40°C of the mixed oil of PET oil A and diester oil B used in Example 4 is 25.0 mm 2 / s.

[0077] In addition, the kinematic viscosity at 40°C is measured in accordance with JIS K 222023. The pour point is measured in accordance with JIS K 2269.

[0078] ·Antioxidants

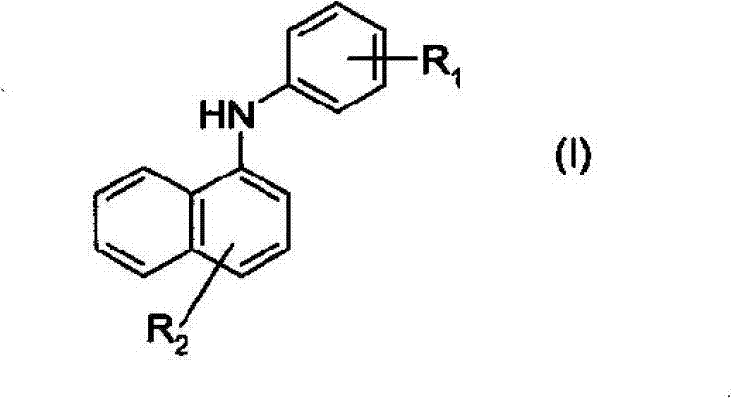

[0079] Antioxidant A: Alkylated N-phenyl-1-naphthylamine (Cas No.68259-36-9)

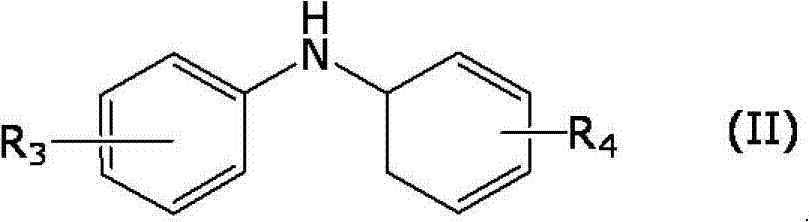

[0080] Antioxidant B: alkylated diphenylamine (Cas No.68411-46-1)

[0081] Antioxidant C: Aromatic amine (Cas No.5285-60-9)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com