Lubricating grease composition for water pump bearing of automobile and preparation method thereof

A grease composition and technology for water pump bearings, applied in the field of grease, can solve the problems of rare patents and reports, and no grease for automobile water pump bearings has been found, and achieve good mechanical stability, good sealing effect, and long oxidation induction period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

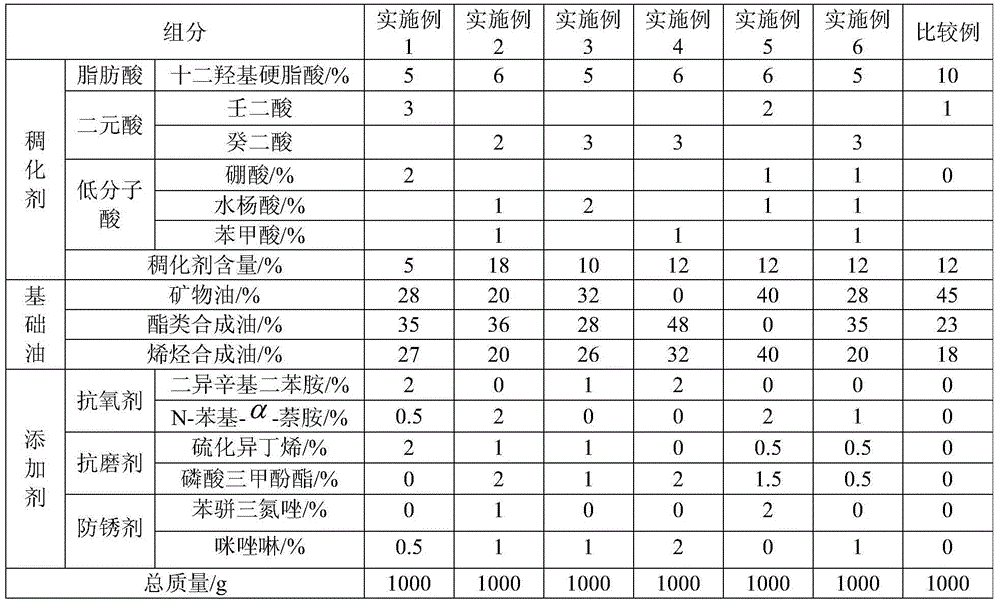

[0024] The present invention will be further elaborated below by specific examples.

[0025] Embodiment 1-6 and comparative example preparation method:

[0026] First, add 40% to 50% of the total amount of base oil in the specified proportion to the reactor. This part of base oil should not contain ester synthetic oil. If the total formula contains grease oil, it should be added in the subsequent steps, and then add 12 -Hydroxystearic acid, stir and heat up to 85-90°C, add 50% lithium hydroxide lye, react for 1-1.5h, control the temperature within the range of 90-100°C; after the one-step alkali reaction is completed, add At least one of the dibasic acids and at least one of the low-molecular acids are reacted for another 1 to 1.5 hours, then the remaining lithium hydroxide lye is added to the reactor, the temperature is raised to drain water, and the temperature is raised to 200 to 220 within 2 hours. ℃, add 20-25% base oil, after quenching, immediately add antioxidant, 95-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com