Lubricating grease composition

A technology of lubricating grease composition and compound, which is applied in the direction of lubricating composition, petroleum industry, thickener, etc. It can solve the problems of poor high temperature resistance, etc., and achieve the effects of reducing production cost, good oxidation stability, and lightening load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

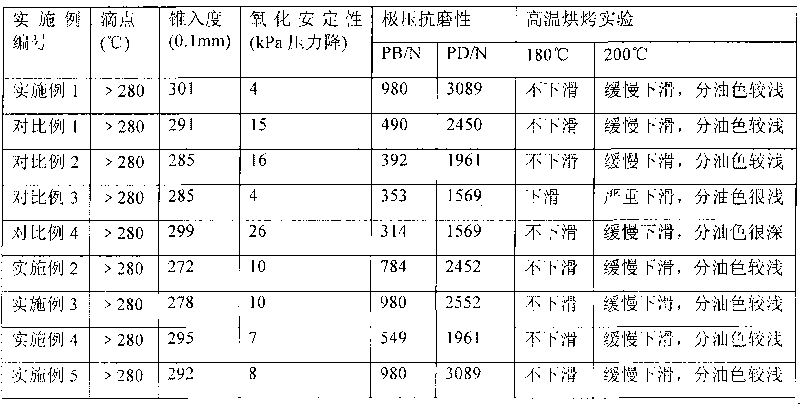

Examples

preparation example Construction

[0017] The preparation method of the lubricating grease composition provided by the invention can be obtained by mixing and uniformly grinding barium complex base grease, lithium complex base grease, sulfur phosphorus additive, and thiadiazolyl compound. Wherein, said compound barium base grease contains compound barium soap and base oil, the preparation method of this compound barium base grease comprises: in the presence of base oil, acid and barium hydroxide are contacted at 60-99 ℃ and dehydration reaction is carried out, and After the reaction, the temperature of the product obtained is raised to 150-220° C., then the heating is stopped, and the grinding is uniform. The lithium complex base grease contains lithium complex and base oil. The preparation method of the lithium complex base grease includes: in the presence of base oil, contacting acid and lithium hydroxide at 60-99°C for dehydration reaction, raising the temperature of the product obtained after the reaction t...

preparation example 1

[0025] Preparation Example 1 is used to illustrate the preparation of composite barium base grease.

[0026] 150g of 12-hydroxystearic acid, 80g of adipic acid and 770g of PAO with a viscosity of 4.0 centistokes were added to a 2.0 liter kettle, stirred and heated to 80°C, and 203.5g of barium hydroxide octahydrate was added, Continue to heat and stir at 100°C for 30 minutes. At this time, the water generated by the reaction and the added water are basically evaporated, and then start to heat up. When the temperature rises to 165°C, stop heating and stirring, and put the reactant on a three-roller mill. Grind three times to obtain the compound barium base fat for future use. In the compound barium base grease, the content of the compound barium soap is 29.22% by weight.

preparation example 2

[0028] Preparation Example 2 is used to illustrate the preparation of lithium complex base grease.

[0029] Add 100g of 12-hydroxystearic acid, 34g of sebacic acid and 466g of PAO with a viscosity of 6.0 centistokes into a 2.0 liter kettle, stir and heat to 95°C, slowly add 28.8g of hydrogen monohydrate The solution made of lithium oxide and 300g water, continue to heat and stir for 30 minutes, when the reaction has been completed, continue to heat and stir to 120°C, keep at 120-130°C for 30 minutes, then continue to heat and stir to 200-210°C , stop heating, add 400g of di-isooctyl sebacate, continue to stir and cool to 120°C, and grind the product three times on a three-roller mill to obtain a lithium complex base grease for future use. In the lithium complex base grease, the content of the lithium complex soap is 13.4% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com