Preparation method of lithium manganese base-enriched ternary composite anode material

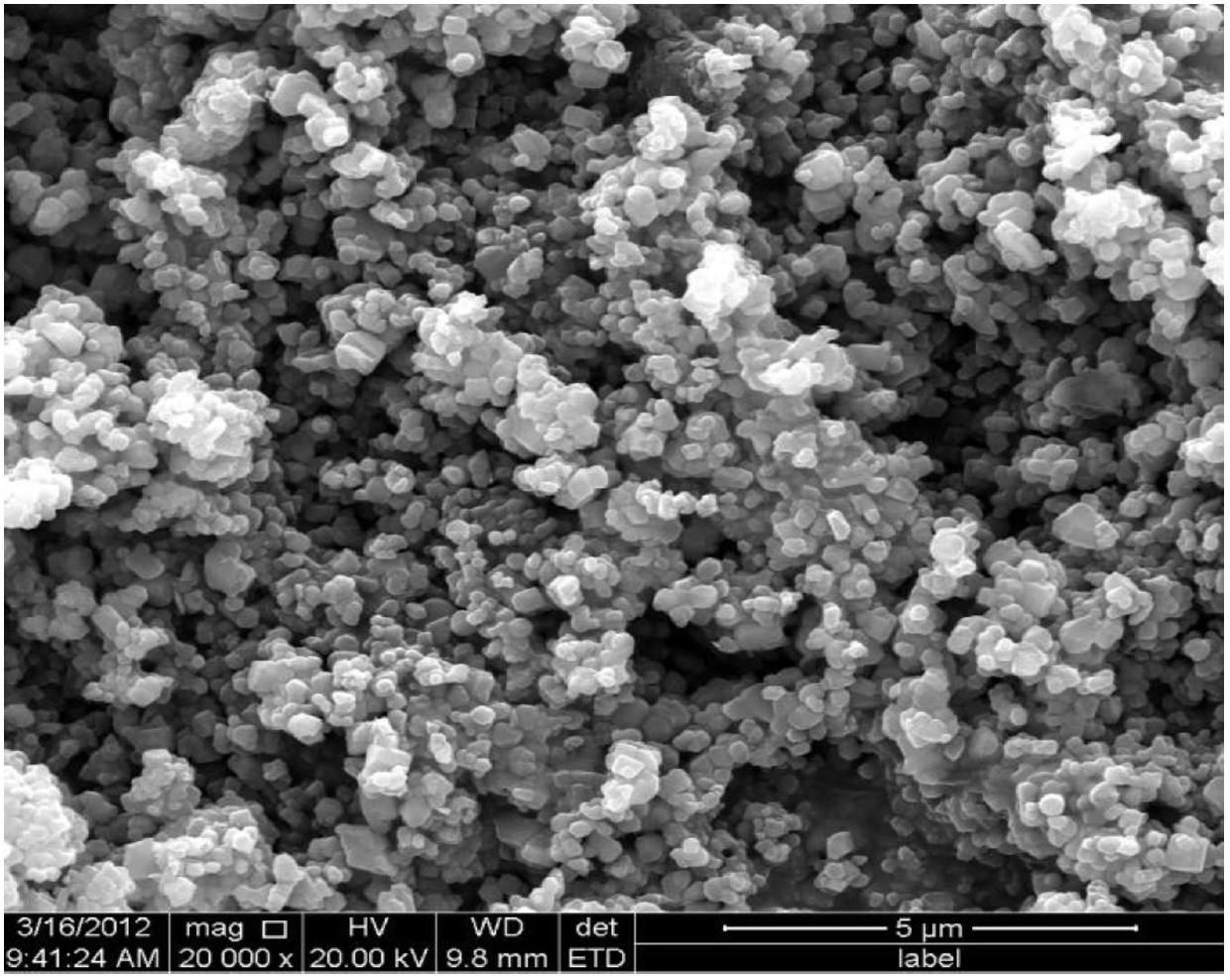

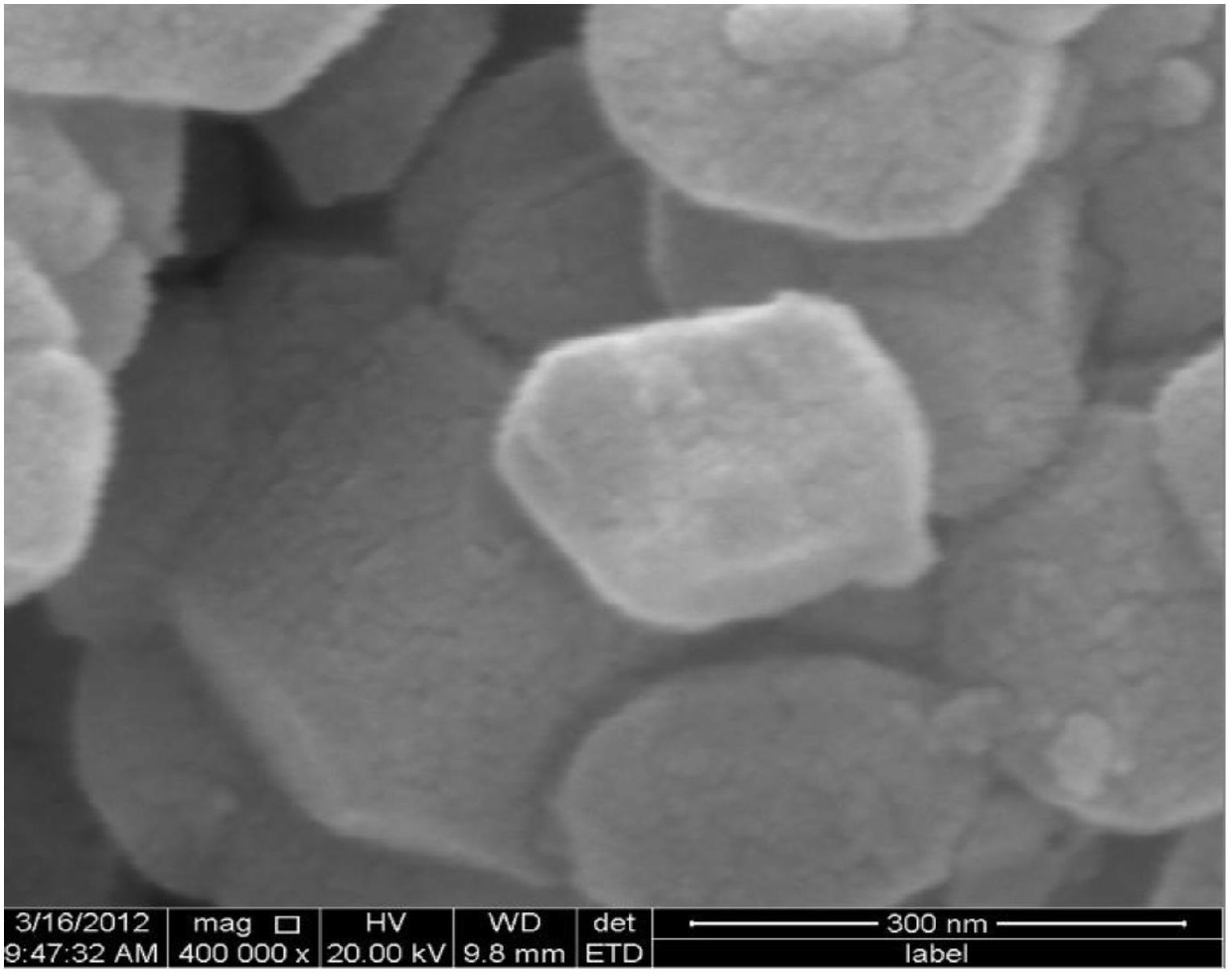

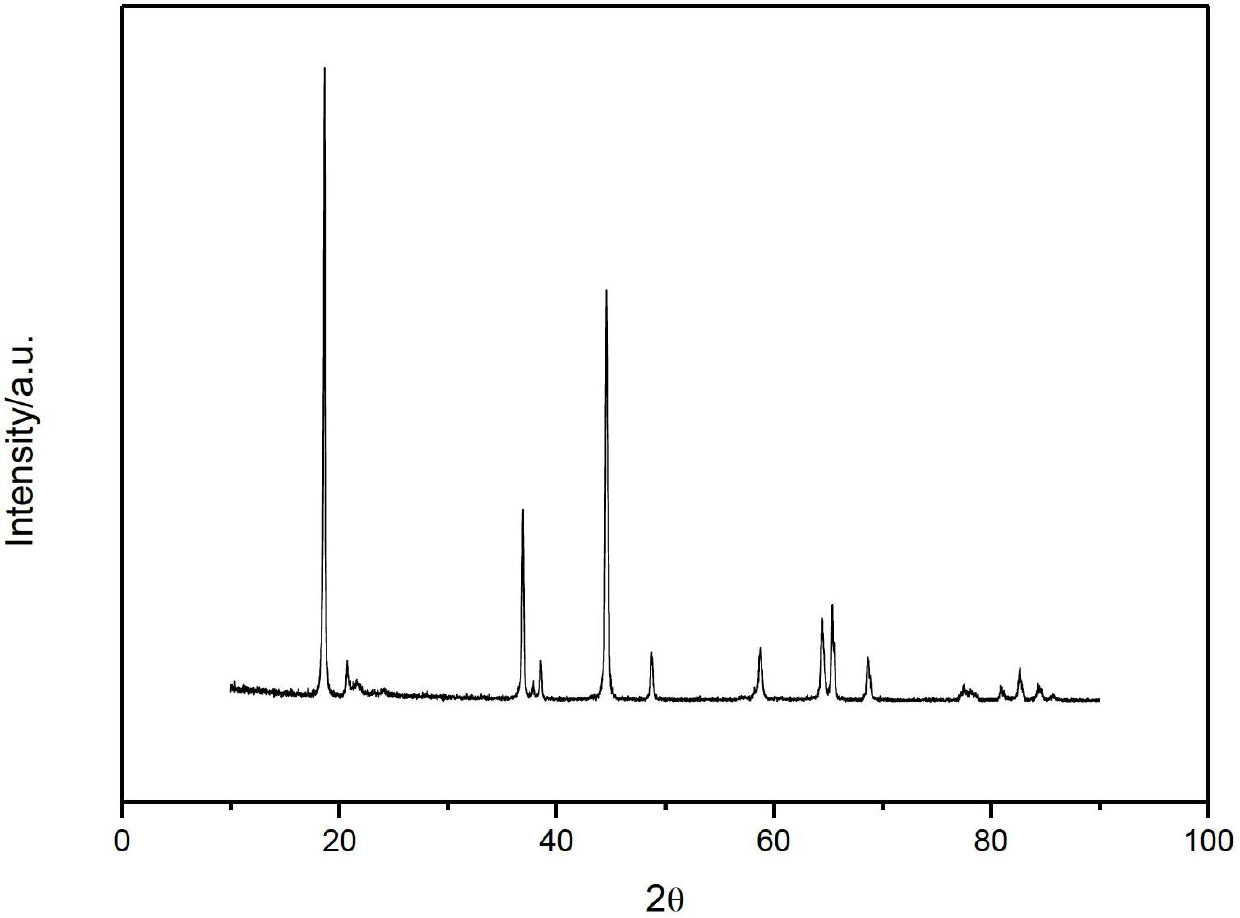

A composite positive electrode material, lithium-rich manganese-based ternary technology, applied in the preparation of lithium-rich manganese-based ternary composite materials, the field of preparation of lithium-rich manganese-based ternary composite positive electrode materials, can solve the problem of large particle size and wide particle size distribution , the first irreversible capacity of particle agglomeration and other issues, to achieve the effect of uniform particle size distribution, high energy density, and reduction of the first irreversible capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Dissolve 0.005 mol of nickel acetate, 0.005 mol of cobalt acetate and 0.02 mol of manganese acetate in 100ml of deionized water, and stir magnetically at 30°C for 4 hours to form a homogeneous mixed solution, in which Ni 2+ :Co 2+ :Mn 2+ The molar ratio of the substances is 1:1:4.

[0043] (2) Dissolve lithium hydroxide in deionized water and stir to dissolve to obtain 60ml of clear lithium hydroxide solution, in which the concentration of lithium hydroxide is 1.25mol / L; add the mixed solution dropwise to lithium hydroxide solution at a rate of 3ml / min The reaction solution was mixed with ammonia water to adjust the pH value of the reaction solution to 11.0, and the reaction solution was placed in a 50°C water bath and stirred at a speed of 120rmp for 3 hours, then aged for 4 hours, and the precipitate was obtained by suction filtration, and washed with distilled water for 3 hours. put the cleaned precipitate into the cold trap, and cool down to -90°C together wit...

Embodiment 2

[0052] (1) Dissolve 0.005mol of nickel acetate, 0.005mol of cobalt acetate and 0.02mol of manganese acetate in 100ml of deionized water, and stir magnetically at 35°C for 2 hours to form a homogeneous mixed solution, in which Ni 2+ :Co 2+ :Mn 2+ The molar ratio of the substances is 1:1:4.

[0053] (2) Dissolve 0.075mol of lithium hydroxide in deionized water and stir to obtain 60ml of clear lithium hydroxide solution, in which the concentration of lithium hydroxide is 1.25mol / L; add the mixed solution dropwise at a rate of 5ml / min. Mix the reaction solution with lithium solution, adjust the pH of the reaction solution to 8.0 with acetic acid, place the reaction solution in a water bath at 35°C at a speed of 100rmp and stir for 6 hours, then age it for 10 hours, filter it with suction to obtain the precipitate, and wash it with distilled water 3 times, and then washed 2 times with anhydrous ethanol to obtain the washed precipitate; first lower the temperature of the cold trap...

Embodiment 3

[0062] (1) Dissolve 0.005mol of nickel acetate, 0.005mol of cobalt acetate and 0.02mol of manganese acetate in 100ml of deionized water, and stir magnetically at 30°C for 12h to form a homogeneous mixed solution, in which Ni 2+ :Co 2+ :Mn 2+ The molar ratio of the substances is 1:1:4.

[0063] (2) Dissolve 2.9372g of lithium hydroxide in deionized water and stir to obtain 100ml of clear lithium hydroxide solution, in which, OH 1- The ratio of the substance to the metal ion is 1.2.1:1; the mixed solution and the lithium hydroxide solution are simultaneously added dropwise to a 60°C beaker at a rate of 10ml / min and mixed to obtain a reaction solution, and a constant temperature magnetic stirrer is used to continuously Stir the reaction solution, adjust the pH value of the reaction solution with acetic acid to be 8.5, stir the reaction at a speed of 500rmp for 3h, then age for 4h, obtain the precipitate by suction filtration, wash and wash 3 times with distilled water, and obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com