Long-life industrial robot RV reducer lubricating grease and preparation method thereof

An industrial robot and lubricating grease technology, which is applied in the field of lubricating grease, can solve the problems of long replacement cycle and achieve the effects of improved service life, excellent friction performance, and excellent anti-wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A preparation method of long-life industrial robot RV reducer grease, comprising the following steps in sequence:

[0035] (1) Mix the fatty acid with part of the base oil and heat it. When the temperature rises to 60-100°C, add dissolved lithium hydroxide and react for 30-90 minutes;

[0036] (2) Continue to heat up at a rate of 0.5-2.0°C. When the temperature rises to 125-175°C, add an antioxidant and react for 10-60 minutes under intermittent stirring.

[0037] (3) Continue to heat up to 180-210°C, react for 1-15min, after the reaction is completed, add the remaining base oil, cool down to 60-100°C, then add extreme pressure anti-wear agent, friction modifier, metal deactivator in sequence , Anti-rust agent, grinding to get grease.

Embodiment 1

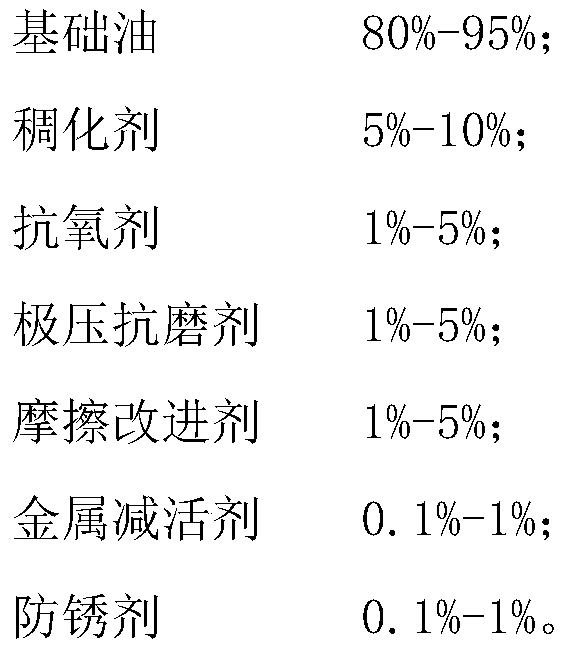

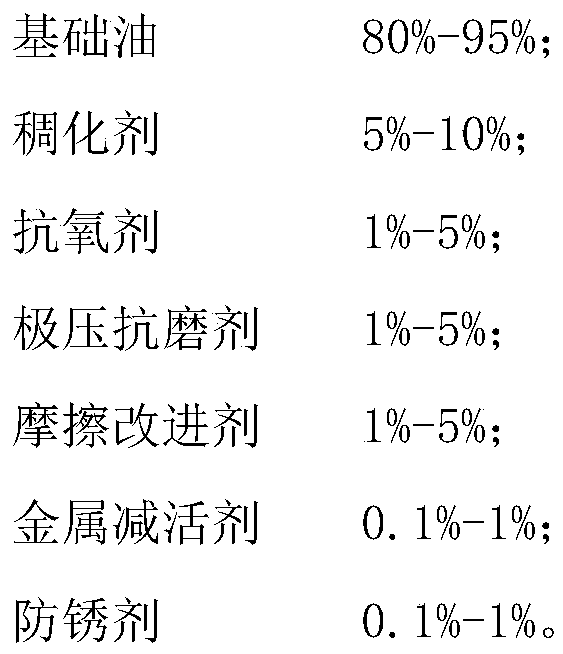

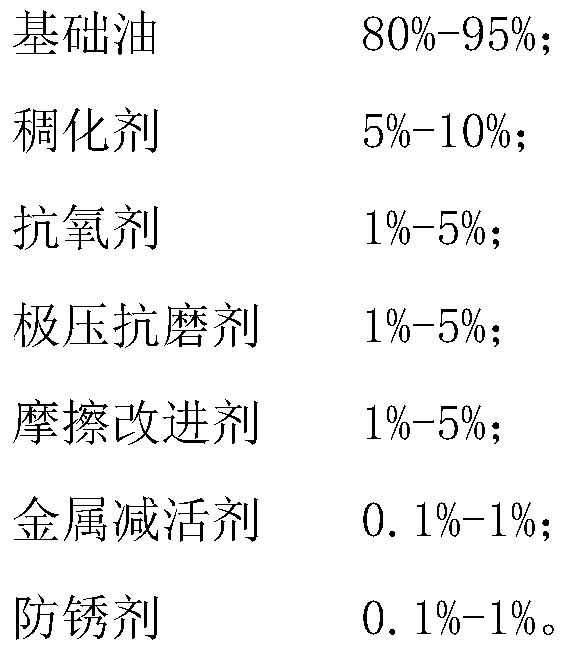

[0039] Prepare 100kg of long-life industrial robot RV reducer grease, which is composed of components including the following parts by weight: thickener is 8kg; antioxidant is 2kg; extreme pressure antiwear agent is 2kg; friction modifier is 2kg; The metal deactivator is 0.5kg; the rust inhibitor is 0.5kg, and the base oil is 85kg. Described thickening agent is lauryl hydroxystearate lithium and lithium stearate; Described antioxidant is the mixture of diphenylamine, high molecular weight phenol, octyl / pentyl diphenylamine; Described extreme pressure resistance The grinding agent is a mixture of sulfurized isobutylene and tricresyl phosphate; the friction modifier is a mixture of sulfurized olefin cottonseed oil, phosphoric acid ester, and organic molybdenum compound; the metal deactivator is N,N-dialkyl A mixture of aminomethylene benzotriazole and thiadiazole derivatives; the rust inhibitor is a mixture of calcium petroleum sulfonate, dodecenyl succinic acid, and lead naphth...

Embodiment 2

[0045] Prepare 100kg of long-life industrial robot RV reducer grease, which consists of the following components by weight: thickener is 6kg; antioxidant is 2.5kg; extreme pressure antiwear agent is 2.5kg; friction modifier is 2kg; metal deactivator 0.3kg; rust inhibitor 0.3kg, base oil 86.4kg. Described thickening agent is lithium dodecyl hydroxystearate; Described antioxidant is the mixture of 2,6-di-tert-p-cresol, high molecular weight phenol, phenyl-alpha-naphthylamine; Described The extreme pressure antiwear agent is a mixture of dibutyl phosphite and sulfurized isobutylene; the friction modifier is a mixture of sulfurized cottonseed oil, phosphoric acid ester, and organic molybdenum compound; the metal deactivator is tolyltriazole The mixture of derivatives and thiadiazole derivatives; the rust inhibitor is a mixture of benzotriazole, dodecenylsuccinic acid and barium petroleum sulfonate.

[0046] The above long-life industrial robot RV reducer grease is prepared by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com