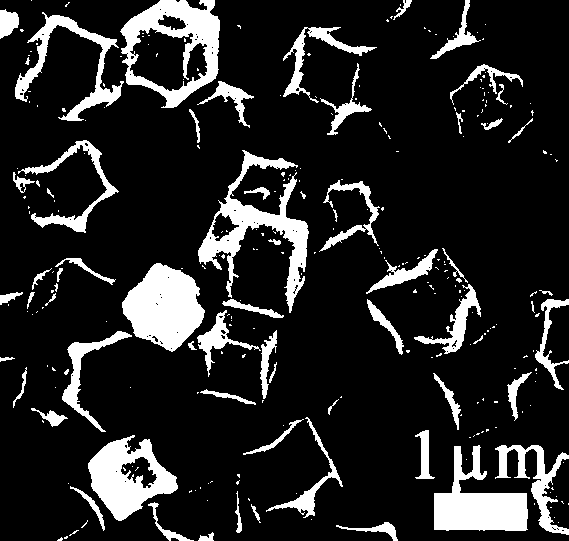

A method for preparing a doped carbon material supported alloy bifunctional electrocatalyst that have a hollow polyhedral nanocage microstructure

An electrocatalyst and microstructure technology, applied in structural parts, circuits, electrical components, etc., can solve problems such as high cost and limited practical application, and achieve the goal of optimizing electronic structure, improving bifunctional electrocatalytic activity, and enhancing electrocatalytic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

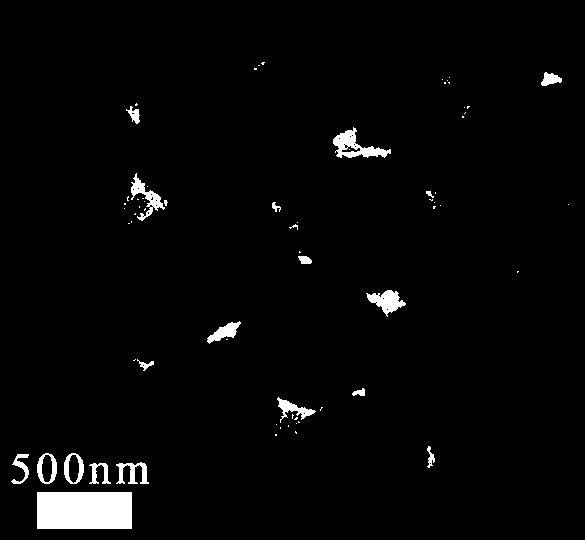

[0025] Step S1: Dissolve 249mg of cobalt nitrate and 328mg of 2-methylimidazole respectively in 25mL of methanol until completely dissolved, then add the cobalt nitrate solution into the 2-methylimidazole solution to form a purple mixed solution, and let it stand at room temperature for 24h , washed several times with methanol and vacuum dried to obtain a purple powder sample, namely the ZIF-67 precursor;

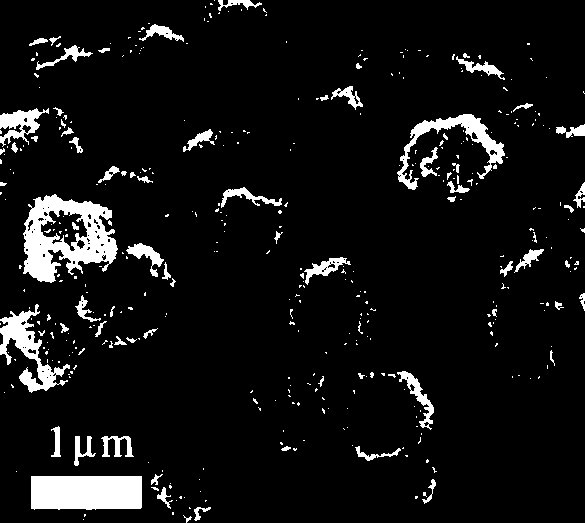

[0026] Step S2: Disperse 80 mg of the ZIF-67 precursor obtained in step S1 and 150 mg of nickel nitrate in 25 mL of methanol, heat it in a water bath to reflux for 0.5 h after the dispersion is uniform, wash with ethanol for several times, and vacuum dry to obtain a light green solid powder;

[0027] Step S3: Add 100 mg of magnesium nitrate and 160 mg of sodium borate to the light green solid powder obtained in step S2, and ultrasonically disperse in 25 mL of ethanol, then react at 90°C for 1 h by solvothermal method, cool naturally to room temperature, and wash several time...

Embodiment 2

[0030] Step S1: Dissolve 249mg of cobalt nitrate and 328mg of 2-methylimidazole respectively in 25mL of methanol until completely dissolved, then add the cobalt nitrate solution into the 2-methylimidazole solution to form a purple mixed solution and let it stand at room temperature for 18h , washed several times with methanol and vacuum dried to obtain a purple powder sample, namely the ZIF-67 precursor;

[0031] Step S2: Disperse 80 mg of the ZIF-67 precursor obtained in step S1 and 80 mg of nickel chloride in 25 m of absolute ethanol, heat it in a water bath to reflux for 1 h after dispersing evenly, wash with ethanol for several times, and vacuum dry to obtain a light green solid powder;

[0032] Step S3: Add 50 mg of magnesium chloride and 80 mg of sodium borate to the light green solid powder obtained in step S2, and ultrasonically disperse in 25 mL of ethanol, then react at 90°C for 0.5 h by solvothermal method, cool naturally to room temperature, and wash several times ...

Embodiment 3

[0035] Step S1: Dissolve 249mg of cobalt nitrate and 328mg of 2-methylimidazole respectively in 25mL of methanol until completely dissolved, then add the cobalt nitrate solution into the 2-methylimidazole solution to form a purple mixed solution, and let it stand at room temperature for 36h , washed several times with methanol and vacuum dried to obtain a purple powder sample, namely the ZIF-67 precursor;

[0036] Step S2: disperse 80 mg of the ZIF-67 precursor obtained in step S1 and 240 mg of nickel-nickel hydroxide in 25 m of absolute ethanol, heat it in a water bath to reflux for 3 hours after the dispersion is uniform, wash with ethanol for several times, and then vacuum-dry to obtain a light green color solid powder;

[0037]Step S3: Add 150mg of magnesium sulfate and 240mg of boron oxide to the light green solid powder obtained in step S2, disperse uniformly in 25mL of ethanol by ultrasonic, then react at 90°C for 3 hours by solvothermal method, cool naturally to room t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com