Hollow porous carbon material as well as preparation method and application thereof

A porous carbon material, hollow technology, applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problems of large sodium ion atomic radius, low product purity, complex synthesis method, etc., to achieve simple and safe synthesis method, simple and easy raw materials high cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

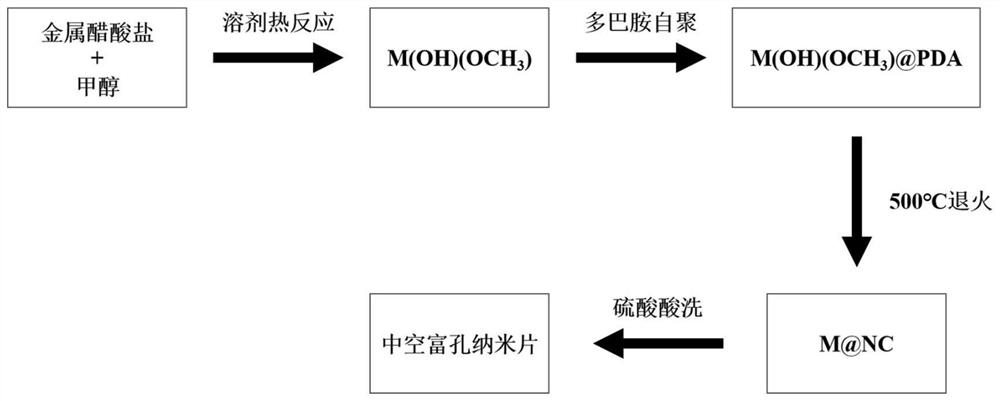

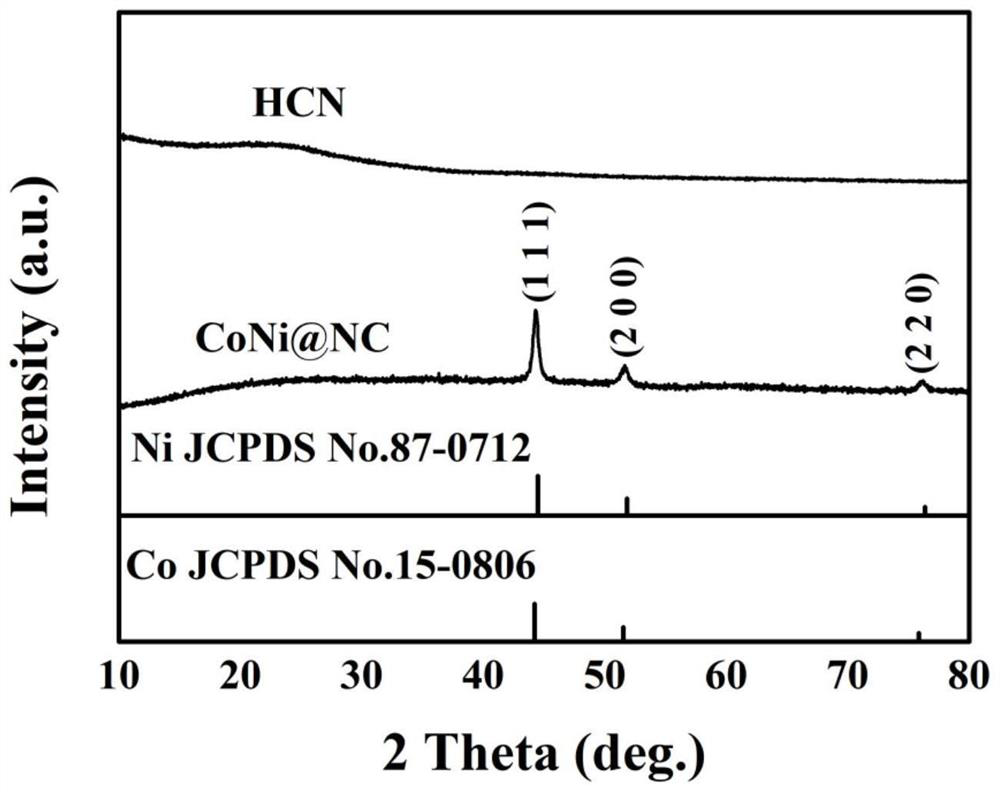

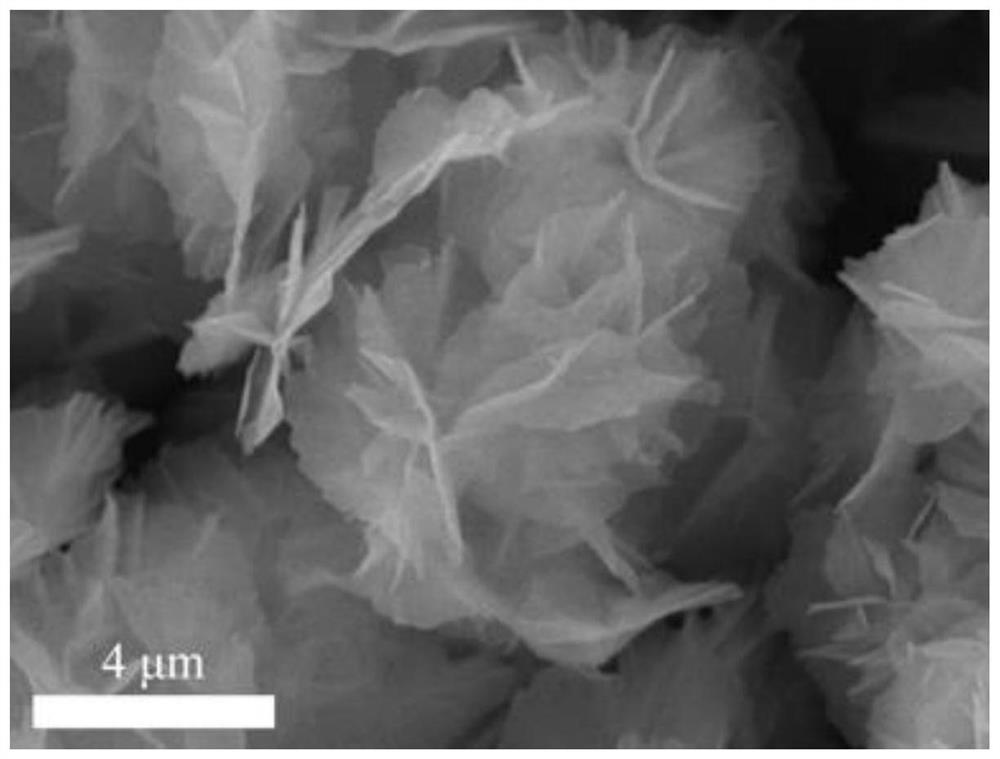

[0044] A hollow carbon nano flower-like material, the preparation method of which comprises the following steps:

[0045] 1) 0.1mol L in a molar ratio of 1:1 -1 Concentration of nickel acetate tetrahydrate (C 4 H 6 NiO 4 ·4H 2 O) and cobalt acetate tetrahydrate (C 4 H 6 CoO 4 ·4H 2 (2) Dissolve in methanol, stir for 1 hour; transfer the well-stirred solution to 100mL polytetrafluoroethylene lining, seal it in a hydrothermal kettle, and perform solvothermal reaction at 180 ° C for 48 hours, and the resulting precipitate will be obtained after the reaction is completed. The product was centrifuged and washed three times with methanol and ethanol, and then vacuum-dried at 60 °C to obtain the precursor nanoflower-like double metal hydroxymethyl hydroxide Ni 0.5 Co 0.5 (OH)(OCH 3 ).

[0046] 2) 10mmol L -1 Tris (Tris) was dissolved in deionized water and stirred for 5 min; 0.1 g Ni was added 0.5 Co 0.5 (OH)(OCH 3 ), ultrasonically dispersed for 20 min to form a homog...

Embodiment 2

[0050] A hollow carbon nano flower-like material, the preparation method of which comprises the following steps:

[0051] 1) Add 0.05mol L in a molar ratio of 1:1 -1 Concentration of nickel acetate tetrahydrate (C 4 H 6 NiO 4 ·4H 2 O) and cobalt acetate tetrahydrate (C 4 H 6 CoO 4 ·4H 2 (2) Dissolve in methanol, stir for 1 hour; transfer the well-stirred solution to 100mL polytetrafluoroethylene lining, seal in a hydrothermal kettle, and perform a solvothermal reaction at 180° C. for 12 hours. After the reaction is completed, the resulting precipitate will be The product was centrifuged and washed three times with methanol and ethanol, and then vacuum-dried at 60 °C to obtain the precursor nanoflower-like double metal hydroxymethyl hydroxide Ni 0.5 Co 0.5 (OH)(OCH 3 ).

[0052] 2) 10mmol L -1 Tris (Tris) was dissolved in deionized water and stirred for 5 min; 0.1 g Ni was added 0.5 Co 0.5 (OH)(OCH 3 ), ultrasonically dispersed for 20 min to form a homogeneous su...

Embodiment 3

[0056] A hollow carbon nano flower-like material, the preparation method of which comprises the following steps:

[0057] 1) 0.2mol L in a molar ratio of 1:1 -1 Concentration of nickel acetate tetrahydrate (C 4 H 6 NiO 4 ·4H 2 O) and cobalt acetate tetrahydrate (C 4 H 6 CoO 4 ·4H 2 (2) Dissolve in methanol, stir for 1 hour; transfer the well-stirred solution to 100mL polytetrafluoroethylene lining, seal it in a hydrothermal kettle, and perform solvothermal reaction at 180°C for 60 hours. After the reaction finishes, the resulting precipitate will be The product was centrifuged and washed three times with methanol and ethanol, and then vacuum-dried at 60 °C to obtain the precursor nanoflower-like double metal hydroxymethyl hydroxide Ni 0.5 Co 0.5 (OH)(OCH 3 ).

[0058] 2) 10mmol L -1 Tris (Tris) was dissolved in deionized water and stirred for 5 min; 0.1 g Ni was added 0.5 Co 0.5 (OH)(OCH 3 ), ultrasonically dispersed for 20 min to form a homogeneous suspension, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com