Bio-based flame-retardant coating and preparation method thereof

A flame retardant coating, bio-based technology, used in fire retardant coatings, epoxy resin coatings, coatings, etc., can solve problems such as damage to life and property, poor compatibility with substrates, and a large amount of smoke and dust, and achieve combustion inhibition, flame retardancy and The effect of improved mechanical properties and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

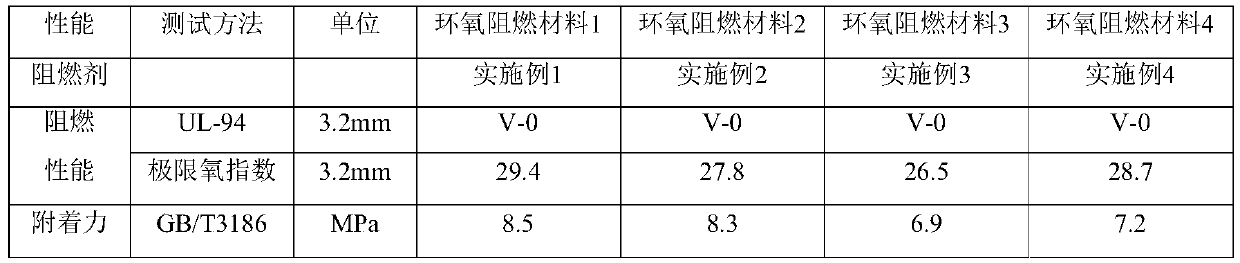

Examples

Embodiment 1

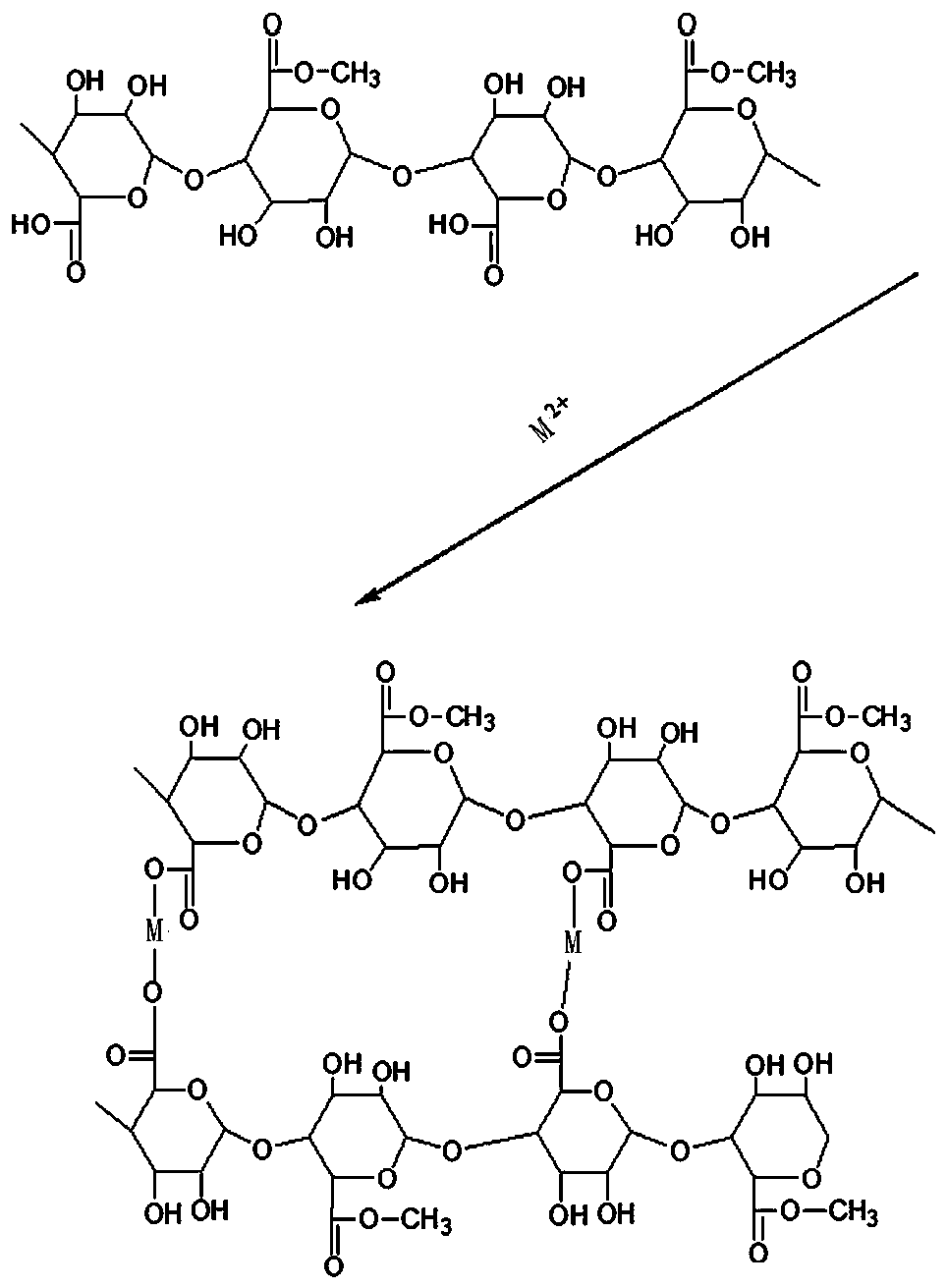

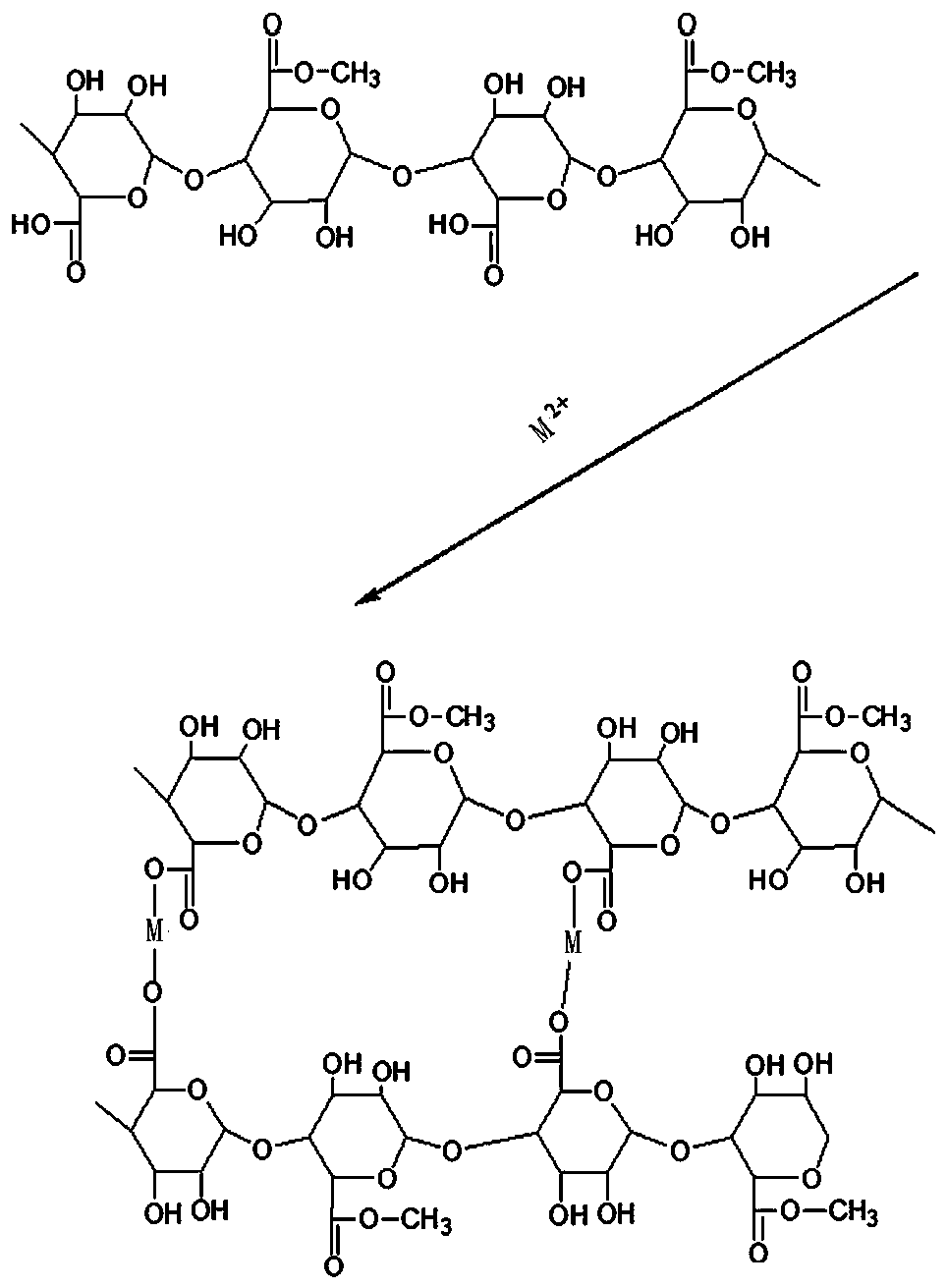

[0032] (1) Preparation of bio-based flame retardants

[0033] Weigh 0.5g of low methoxyl pectin powder and dissolve it in 10ml of distilled water, and add 0.25g of calcium chloride. Prepare a sodium hydroxide solution with a mass fraction of 3%, adjust the pH value to 3 with the sodium hydroxide solution, raise the temperature to 60° C., and react for 1 h. After centrifugal washing, put into the oven until dry;

[0034] (2) Preparation of bio-based flame retardant coatings

[0035] Take 30 parts of a bio-based flame retardant as a filler, add it to a mixture of 100 parts of water and 200 parts of epoxy resin, and disperse it with a ball mill for 2 hours to obtain a mother liquor of a bio-based flame-retardant coating;

[0036] Take 30 parts of curing agent and 60 parts of water and mix evenly with the mother liquor of bio-based flame retardant coating according to the ratio of 1:2.

[0037] The water-based epoxy resin is 828 epoxy resin, and the water-based curing agent is ...

Embodiment 2

[0039] (1) Preparation of bio-based flame retardants

[0040] Weigh 0.5g of low methoxyl pectin powder and dissolve it in 10ml of distilled water, add 0.25g of calcium chloride to prepare a sodium hydroxide solution with a mass fraction of 3%, adjust the pH value to 4 with the sodium hydroxide solution, and raise the temperature To 60°C, react for 1h. After centrifugal washing, put into the oven until dry;

[0041] (2) Preparation of bio-based flame retardant coatings

[0042] Take 30 parts of a bio-based flame retardant as a filler, add it to a mixture of 100 parts of water and 200 parts of epoxy resin, and disperse it with a ball mill for 2 hours to obtain a mother liquor of a bio-based flame-retardant coating;

[0043] Take 30 parts of curing agent and 60 parts of water and mix evenly with the mother liquor of bio-based flame retardant coating according to the ratio of 1:2.

[0044] The water-based epoxy resin is 828 epoxy resin, and the water-based curing agent is Aq419...

Embodiment 3

[0046] (1) Preparation of bio-based flame retardant

[0047] Weigh 0.5g of low methoxyl pectin powder and dissolve it in 10ml of distilled water, add 0.25g of calcium chloride to prepare a sodium hydroxide solution with a mass fraction of 3%, adjust the pH value to 5 with the sodium hydroxide solution, and raise the temperature to 60°C, react for 1h. After centrifugal washing, put into the oven until dry;

[0048] (2) Preparation of bio-based flame retardant coatings

[0049] Take 30 parts of a bio-based flame retardant as a filler, add it to a mixture of 100 parts of water and 200 parts of epoxy resin, and disperse it with a ball mill for 2 hours to obtain a mother liquor of a bio-based flame-retardant coating;

[0050] Take 30 parts of curing agent and 60 parts of water and mix evenly with the mother liquor of bio-based flame retardant coating according to the ratio of 1:2.

[0051] The water-based epoxy resin is 828 epoxy resin, and the water-based curing agent is Aq419....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com