Co(at) NiSx-CNT electrode material as well as preparation method and application thereof

An electrode material and electrocatalytic technology, applied in the field of hydrogen energy, can solve the problems of not achieving good results, achieve excellent electrochemical performance, increase the specific surface area, and the synthesis method is simple and safe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Cobalt acetate 0.75mmol

[0039] Nickel acetate 1.0mmol

[0040] Thioacetamide 7mmol

[0041] Carbon nanotubes 10mg

[0042] N,N-Dimethylformamide 25mL

[0043] The electrode material is prepared by the preparation method of the following steps:

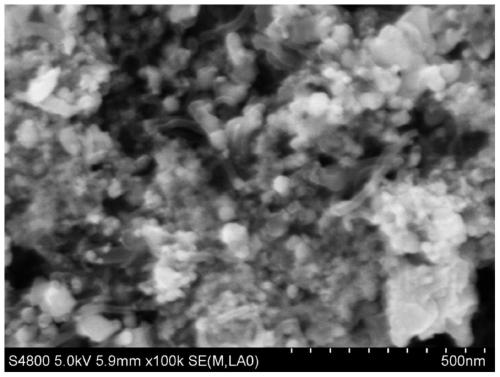

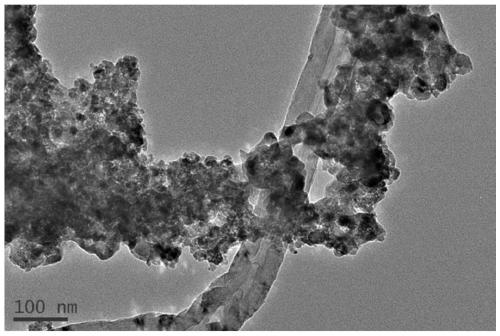

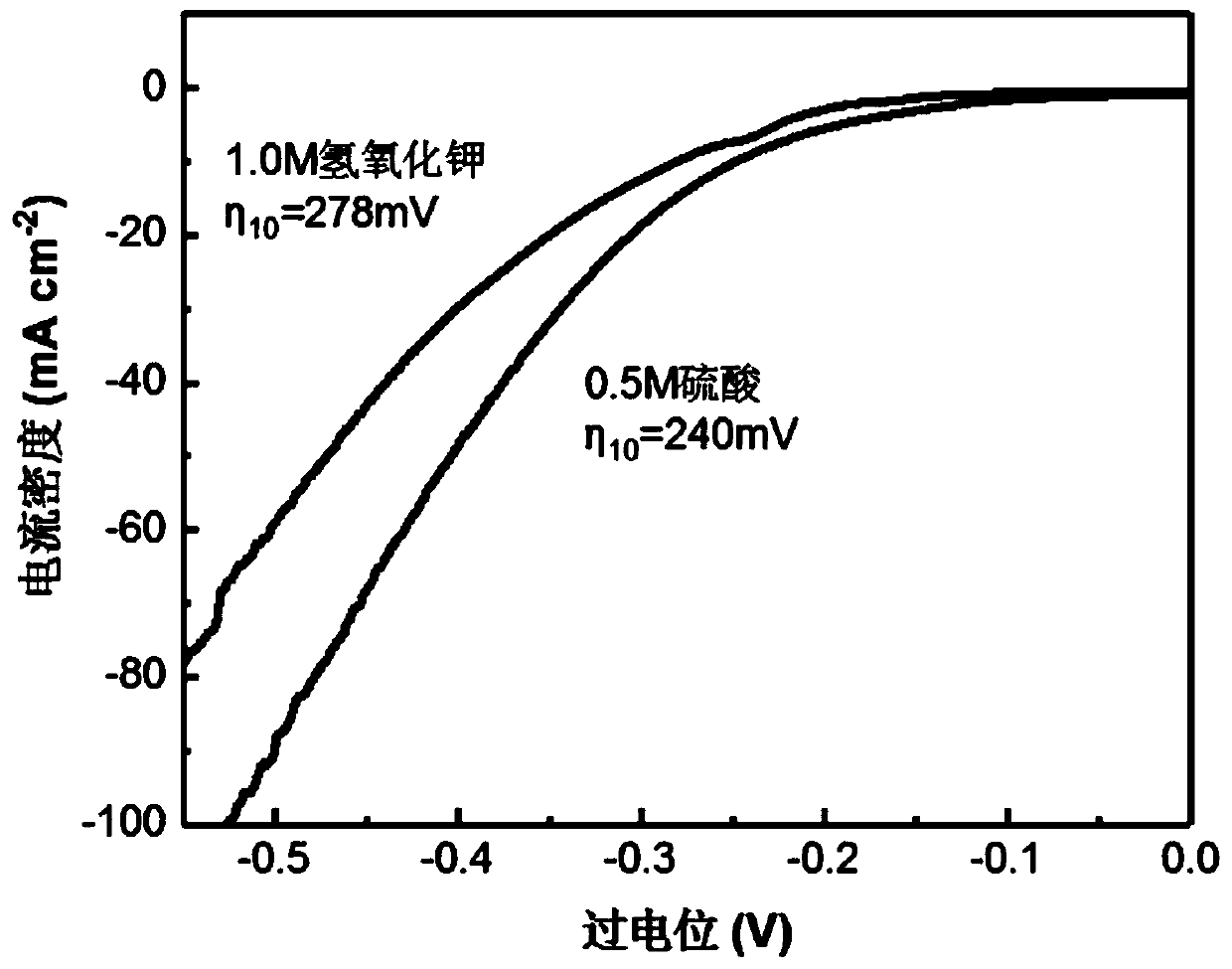

[0044] Mix 0.75mmol of cobalt acetate, 1.0mmol of nickel acetate, 7mmol of thioacetamide and 25mL of N,N-dimethylformamide, ultrasonically disperse for 20min; add 10mg of carbon nanotubes to the solution and ultrasonically disperse for 5min; Move it to a hydrothermal autoclave and heat it at 160°C for 20 hours, centrifuge the solution obtained by hydroheating to collect the precipitate, and dry the precipitate in a vacuum oven at 60°C for 16 hours to obtain the Co@NiSx-CNT electrode material. The specific surface area of the material is 95.6m 2 / g. figure 1 , the translucent tubes are carbon nanotubes, and it can be seen that carbon nanotubes and cobalt-nickel sulfide are densely combined. figure 2 , it can be seen t...

Embodiment 2

[0051] Cobalt acetate 0.5mmol

[0052] Nickel acetate 2.0mmol

[0053] Thioacetamide 10mmol

[0054] Carbon nanotubes 20mg

[0055] N,N-Dimethylformamide 50mL

[0056] The electrode material is prepared by the preparation method of the following steps:

[0057] Mix 0.5mmol of cobalt acetate, 2.0mmol of nickel acetate, 10mmol of thioacetamide and 50mL of N,N-dimethylformamide, and ultrasonically disperse for 20min; add 20mg of carbon nanotubes to the solution and ultrasonically disperse for 8min; Move to a hydrothermal autoclave and heat at 180°C for 12 hours, centrifuge the solution obtained by hydroheating to collect the precipitate, and dry the precipitate in a vacuum oven at 60°C for 16 hours to obtain the Co@NiSx-CNT electrode material. The specific surface area of the material is 78.2m 2 / g.

Embodiment 3

[0064] Cobalt acetate 0.2mmol

[0065] Nickel acetate 2.0mmol

[0066] Thioacetamide 15mmol

[0067] Carbon nanotubes 12mg

[0068] N,N-Dimethylformamide 40mL

[0069] The electrode material is prepared by the preparation method of the following steps:

[0070] Mix 0.2mmol cobalt acetate, 2.0mmol nickel acetate, 15mmol thioacetamide and 40mL N,N-dimethylformamide, and ultrasonically disperse for 30min; add 12mg of carbon nanotubes to the solution and ultrasonically disperse for 10min; Move to a hydrothermal autoclave and heat at 200°C for 18 hours, centrifuge the solution obtained from the hydroheating to collect the precipitate, and dry the precipitate in a vacuum oven at 90°C for 24 hours to obtain the Co@NiSx-CNT electrode material. The specific surface area of the material is 81.7m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Overpotential | aaaaa | aaaaa |

| Overpotential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com