Anode material of lead-acid battery and its production method

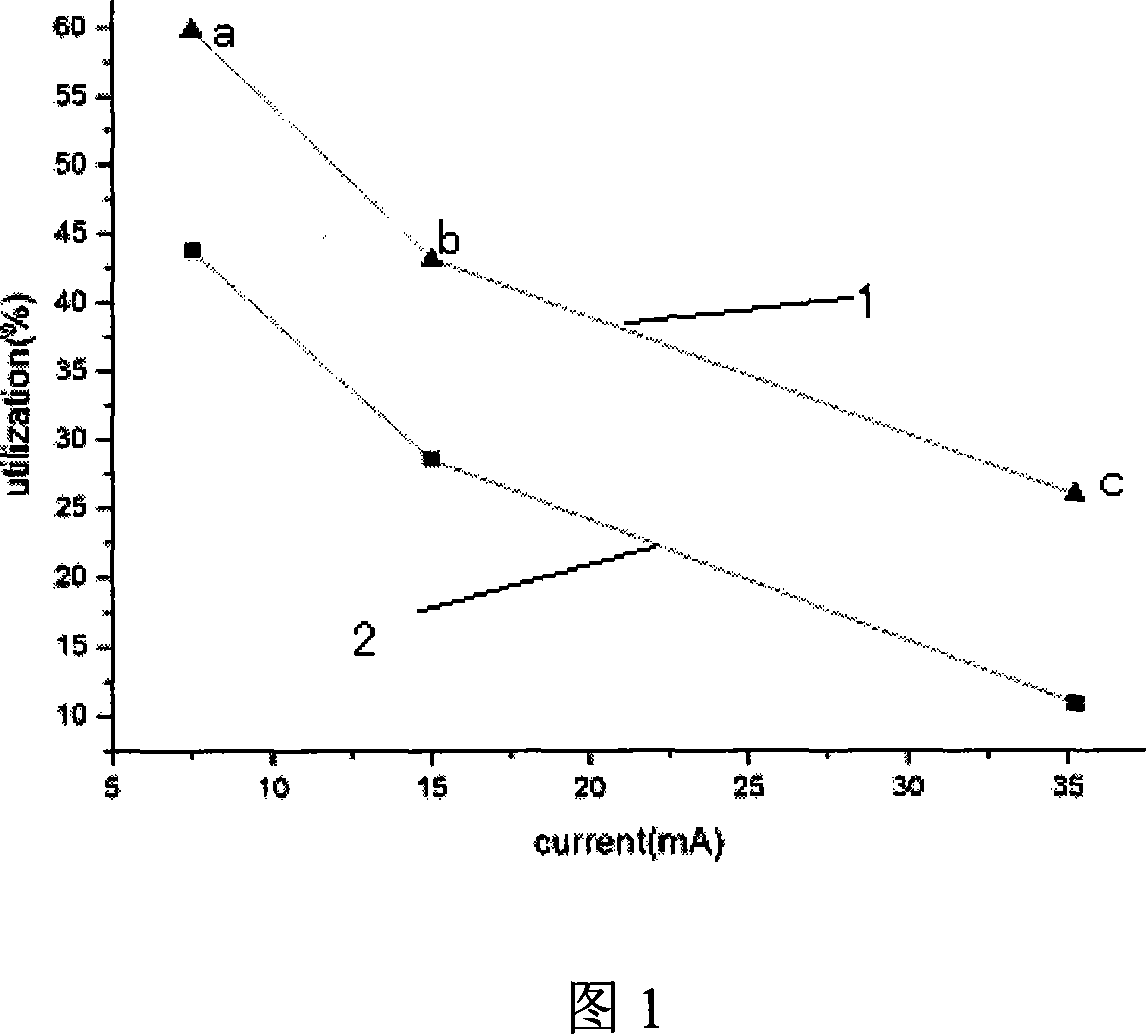

A technology for positive electrode materials and lead-acid batteries, applied in the direction of lead-acid battery electrodes, battery electrodes, circuits, etc., can solve problems such as loss of function, and achieve the effects of increasing utilization, improving formation efficiency, and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Mix 50g of concentrated sulfuric acid and 25g of concentrated nitric acid, then add 0.1g of sodium dodecylbenzenesulfonate and 0.1g of carbon nanotubes, stir and mix, then sonicate for 1 hour, add deionized water to dilute and suction filter until neutral, bake at 60°C 8h, to obtain mixed acid ultrasonic treatment of carbon nanotubes; then put the mixed acid ultrasonic treatment of carbon nanotubes in a quartz boat with a diameter of 100mm, under the protection of nitrogen atmosphere, at 800 ° C, keep warm for 8h, cool with the furnace, and obtain medium and low temperature graphitization Dealing with carbon nanotubes.

[0025] 2) Combine 0.1g short fiber with 35g PbO 2 Powder and 14.9g of lead powder were mixed evenly.

[0026] 3) Put the mixture of medium and low temperature graphitized carbon nanotubes and step 2) into an agate ball mill jar at a mass ratio of 1:99, add 3ml of absolute ethanol dropwise, and ball mill at a speed of 200r / min for 2 hours to obtain t...

Embodiment 2

[0029] 1) Mix 40g of concentrated sulfuric acid and 10g of concentrated nitric acid, then add 0.12g of polyvinyl alcohol and 0.1g of carbon nanotubes, stir and mix, then sonicate for 0.5h, add deionized water to dilute and filter until neutral, bake at 80°C for 10h, and obtain mixed acid sonication Treat the carbon nanotubes; place the carbon nanotubes that have been ultrasonically treated with mixed acid in a quartz boat with a diameter of 100mm, and keep them at 900°C for 10h under the protection of a nitrogen atmosphere, and cool with the furnace to obtain graphitized carbon nanotubes.

[0030] 2) Combine 1g short fiber with 45g PbO 2 Powder and 4g lead powder are mixed evenly.

[0031] 3) Put the mixture of medium and low temperature graphitized carbon nanotubes and step 2) into an agate ball mill jar at a mass ratio of 0.2:99.8, add 5ml of absolute ethanol dropwise therein, and ball mill at a speed of 200r / min for 3 hours to obtain the apparent density 3.8g / cm 3 positiv...

Embodiment 3

[0034] 1) Mix 50g of concentrated sulfuric acid and 50g of concentrated nitric acid, then add 0.2g of sodium dodecylbenzenesulfonate and 0.4g of carbon nanotubes, stir and mix, then sonicate for 2 hours, add deionized water to dilute and filter until neutral, and bake at 100°C After 12 hours, the mixed acid ultrasonically treated carbon nanotubes were obtained; then the carbon nanotubes treated by mixed acid ultrasonically were placed in a quartz boat with a diameter of 100mm, kept at 1200°C for 12h under the protection of a nitrogen atmosphere, and cooled with the furnace to obtain graphitized carbon nanotubes. nanotube.

[0035] 2) Combine 0.5g short fiber with 30g PbO 2 Powder and 19.5g of lead powder were mixed evenly.

[0036] 3) Put the mixture of medium and low temperature graphitized carbon nanotubes and step 2) into an agate ball mill jar at a mass ratio of 2:98, add 4ml of absolute ethanol dropwise therein, and ball mill at a speed of 400r / min for 1 hour to obtain t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com