Buried tube type bubbling bed direct carbon fuel cell

A fuel cell and bubbling bed technology, applied in the field of direct carbon fuel cell devices, can solve unfavorable carbon and anode direct contact mechanism reaction, anode surface solid carbon fuel feeding problem, unfavorable carbon and anode non-contact mechanism reaction, etc. problems, to achieve the effect of easy sealing, convenient current collection, and less carrier gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

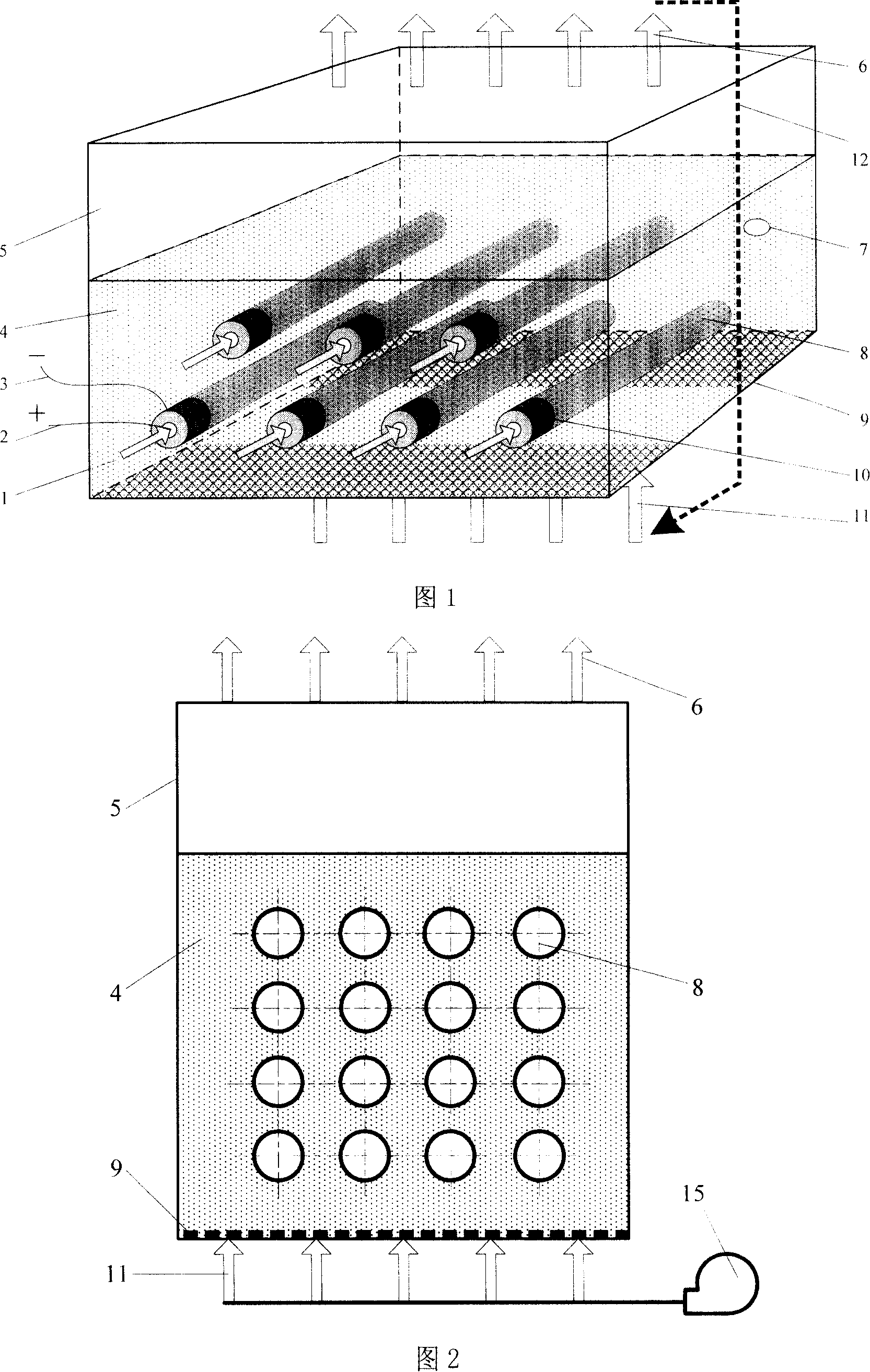

[0032] A buried tube type bubbling bed direct carbon fuel cell, which includes a bubbling bed 5, 16 dead-tube solid oxide fuel cell cells 8 with an anode on the outside and a cathode on the inside, and an air distribution plate 9 with a diameter of 5mm ~50μm powdered solid carbon fuel—graphite 4 and air supply device 15;

[0033] As shown in Fig. 2, Fig. 2 is a schematic diagram of the structure of the parallel buried tube type bubbling bed in Embodiment 1. The air distribution plate 9 is installed at the bottom of the bubbling bed 5, and 16 dead-pipe solid oxide fuel cell cells 8 are inserted into the bubbling bed 5 along the horizontal direction, and the open ends of the dead-pipe solid oxide fuel cell cells 8 are located in the bubbling bed. Outside the bubble bed 5, the closed end is located inside the bubble bed 5, and the joint between the bubble bed 5 and the solid oxide fuel cell unit 8 is sealed with high-temperature ceramic glue 10, and the interface structure is sho...

Embodiment 2

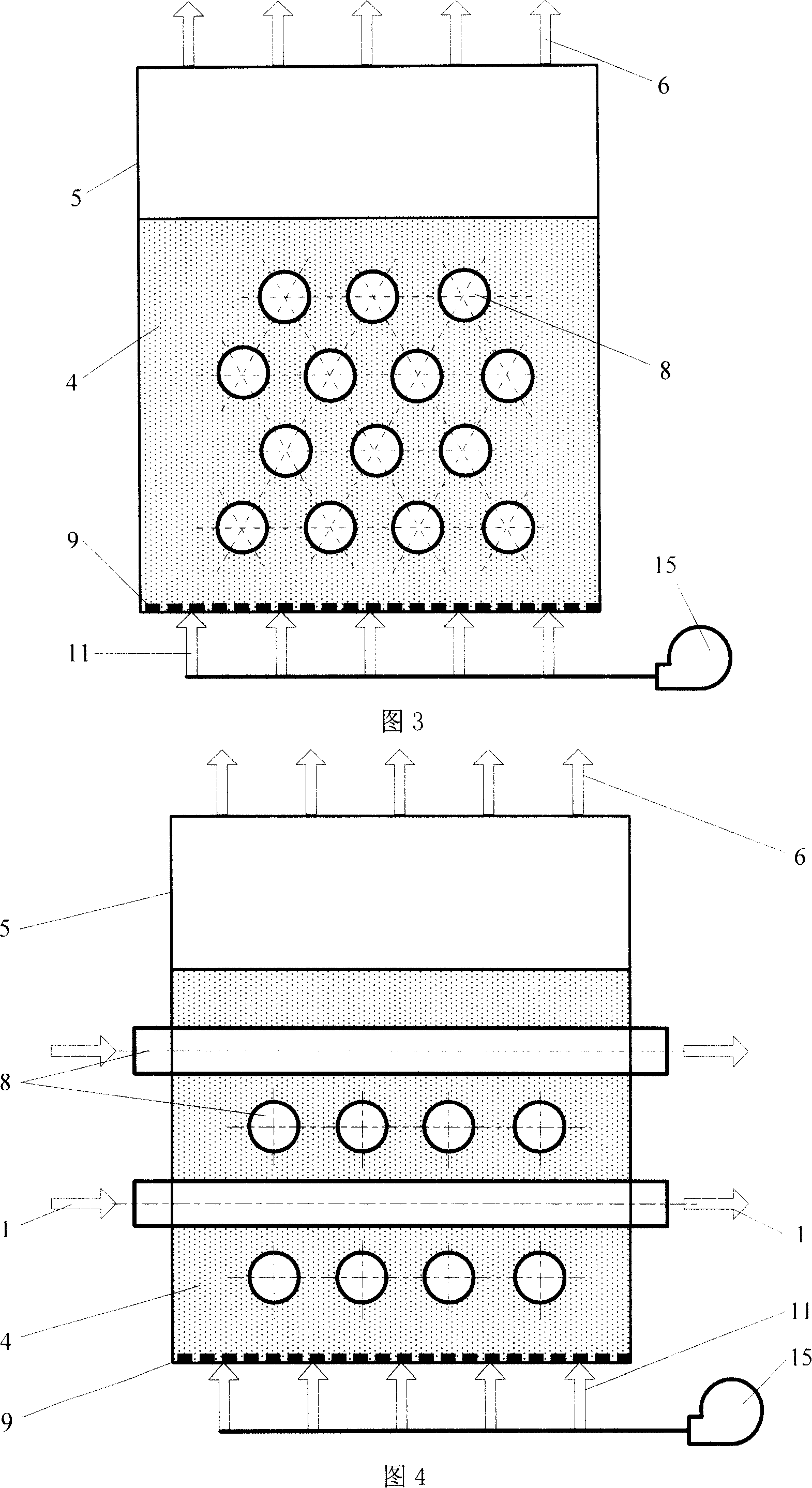

[0037] A buried tube type bubbling bed direct carbon fuel cell, which includes: bubbling bed 5, 14 blind tube solid oxide fuel cell cells 8 with anodes on the outside and cathodes on the inside, and an air distribution plate 9 with a diameter of 5mm-50μm powdered solid carbon fuel—coke 4 and air supply device 15.

[0038] As shown in Fig. 3, Fig. 3 is a schematic diagram of the structure of the fork row buried tube type bubbling bed in Embodiment 2. Install the air distribution plate 9 on the bottom of the bubbling bed 5, insert 14 dead-pipe solid oxide fuel cell cells 8 into the bubbling bed 5 along the horizontal direction, and open the open ends of the dead-pipe solid oxide fuel cell cells 8 Located outside the bubbling bed 5, the closed end is located inside the bubbling bed 5, and the joint between the bubbling bed 5 and the solid oxide fuel cell unit 8 is sealed with high-temperature ceramic glue 10, and the interface structure is shown in Figure 8. Embodiment 2 Solid o...

Embodiment 3

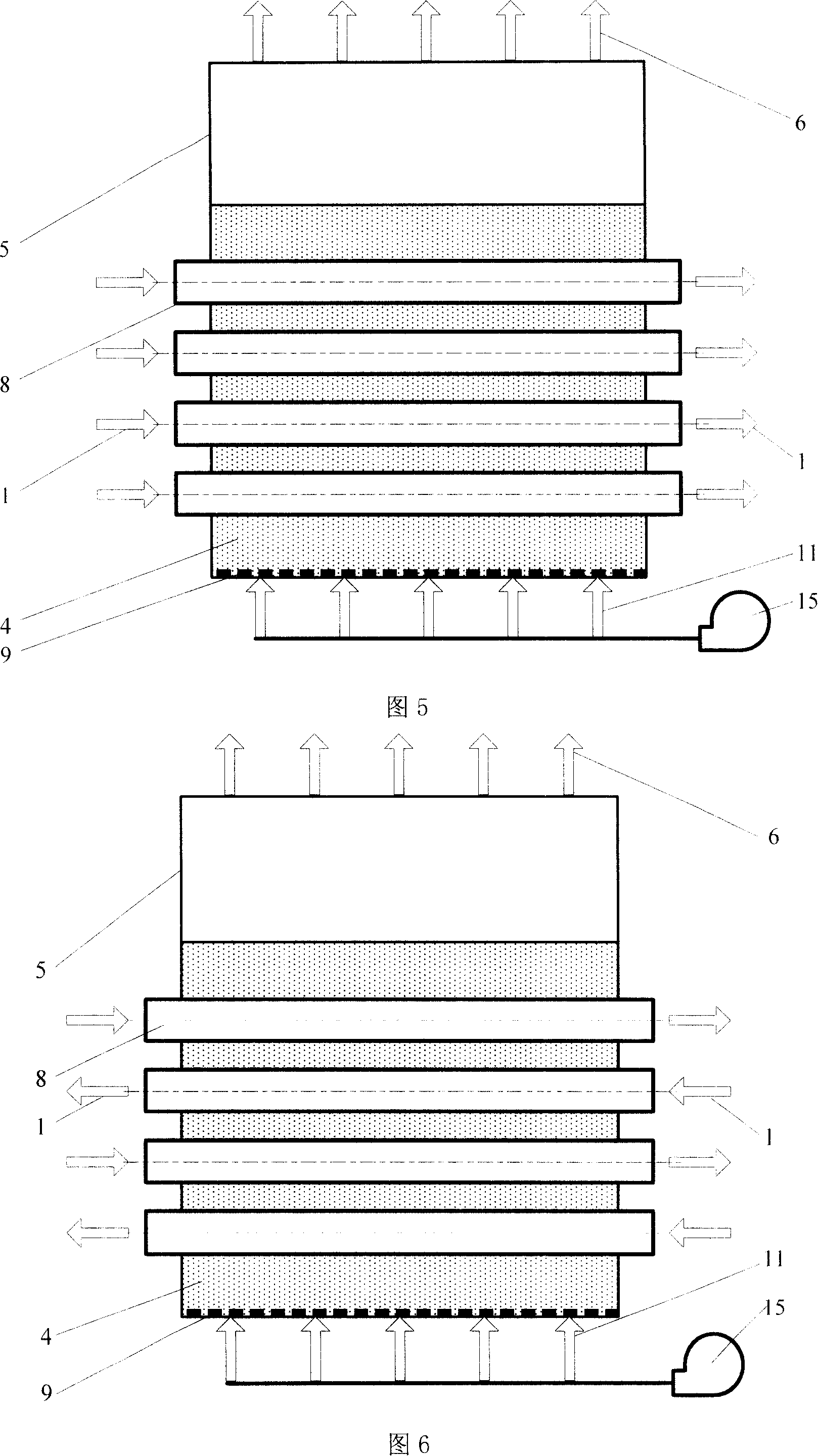

[0042] A buried tube type bubbling bed direct carbon fuel cell, which includes: bubbling bed 5, 16 through-tube solid oxide fuel cell cells 8 with an anode on the outside and a cathode on the inside, and an air distribution plate 9 with a diameter of 5mm-50μm powdered solid carbon fuel——carbon black 4 and air blower 15 .

[0043] As shown in Figure 4, the air distribution plate 9 is installed at the bottom of the bubbling bed 5, and 16 through-tube solid oxide fuel cell cells 8 are inserted into the bubbling bed 5 along the horizontal direction, and the through-tube solid oxide fuel cell The open ends on both sides of the battery cell 8 are located outside the bubbling bed 5, and the joint between the bubbling bed 5 and the solid oxide fuel cell 8 is sealed with high-temperature ceramic glue 10. The interface structure on both sides of the tube is shown in Figure 9 Show. Embodiment 3 Solid oxide fuel cell cells 8 are arranged layer by layer in a staggered arrangement. The po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com