Device using AB-ASBR reactors to start anaerobic ammonia oxidation

A technology of anaerobic ammonium oxidation and reaction device, which is applied in the field of biological treatment of sewage sludge, can solve the problems of unstable bacterial dominance, limitation of reactor volume load, and reduction of infrastructure investment, so as to save treatment cost and floor area, Improve the efficiency of sewage treatment and accelerate the effect of adsorption process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The method of the present invention will be described in detail below in conjunction with the accompanying drawings.

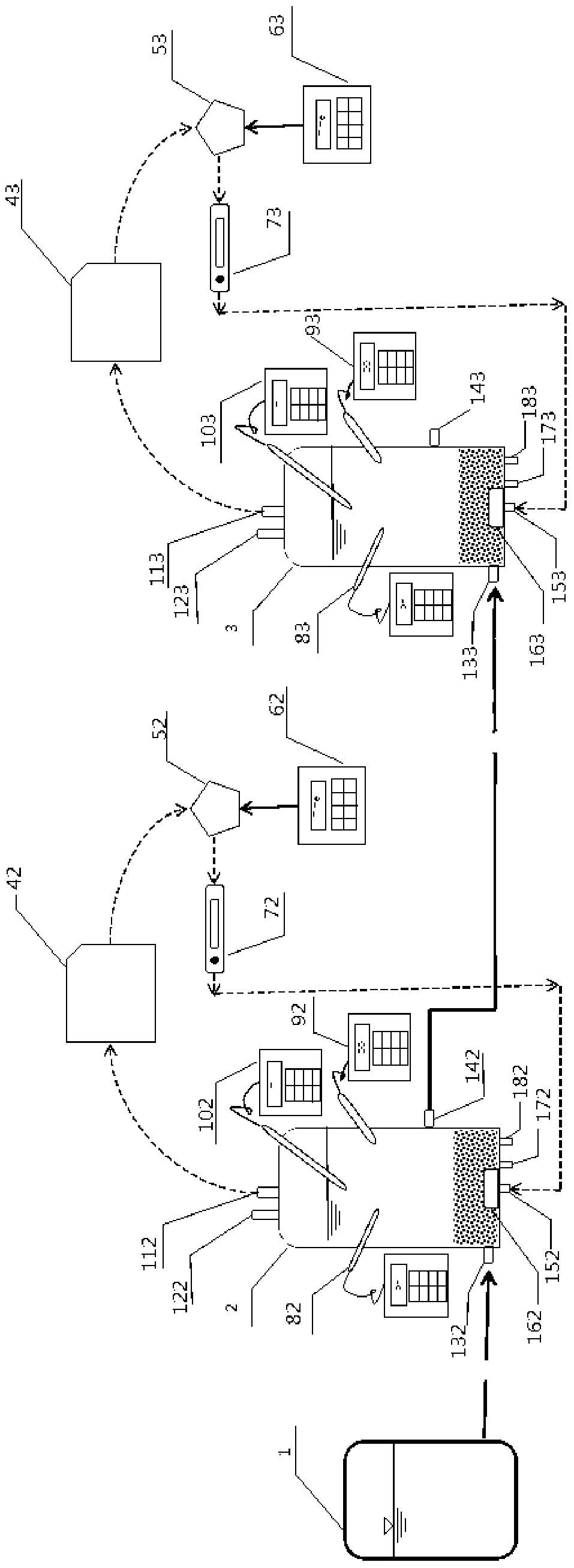

[0024] Such as figure 1 Shown, a kind of AB-ASBR reactor of the present invention starts the device of anaerobic ammonium oxidation, comprises: sewage tank 1, front stage reaction device and back stage reaction device;

[0025] A device for starting anaerobic ammonium oxidation in an AB-ASBR reactor, comprising: a sewage tank 1, a front-stage reaction device and a rear-stage reaction device;

[0026] The front-stage reaction device includes the front-stage ASBR reactor 2, gas collection device 42, miniature vacuum pump 52, time control switch 62, gas flow meter 72, pH measuring instrument 82, dissolved oxygen measuring instrument 92 and temperature control device 102;

[0027] The back stage reaction device includes the back stage ASBR reactor 3, gas collection device 43, micro vacuum pump 53, time control switch 63, gas flow meter 73, pH measuring ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com