Flexible thin-film electrode and preparation method and application thereof

A flexible thin film and electrode technology, which is applied in the field of electrodes and its preparation, achieves the effects of low cost, simple process and uniform growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Add 0.02M potassium permanganate solution and 0.03M potassium manganate solution to 50mL of 0.25mg / mL carbon nitride aqueous phase dispersion respectively, stir at room temperature for 30 minutes, and centrifuge to wash An electroactive material composed of carbon nitride and manganese oxide is obtained. The composite of carbon nitride and manganese oxide is uniformly dispersed in water to form an electroactive material dispersion with a concentration of 0.1 mg / mL.

[0039] 1g of carbon nanotubes were purified in advance at 500°C for 1 hour, then 23mL of concentrated sulfuric acid was added and stirred at room temperature for 20 hours, then 350mg of sodium nitrate and 1g of potassium permanganate were added, stirred at 40°C for 2 hours and then 10mL 30% was added The oxidized modified carbon nanotubes are obtained by centrifugal washing with hydrogen peroxide water, which is dispersed in water to obtain an aqueous solution of carbon nanotubes.

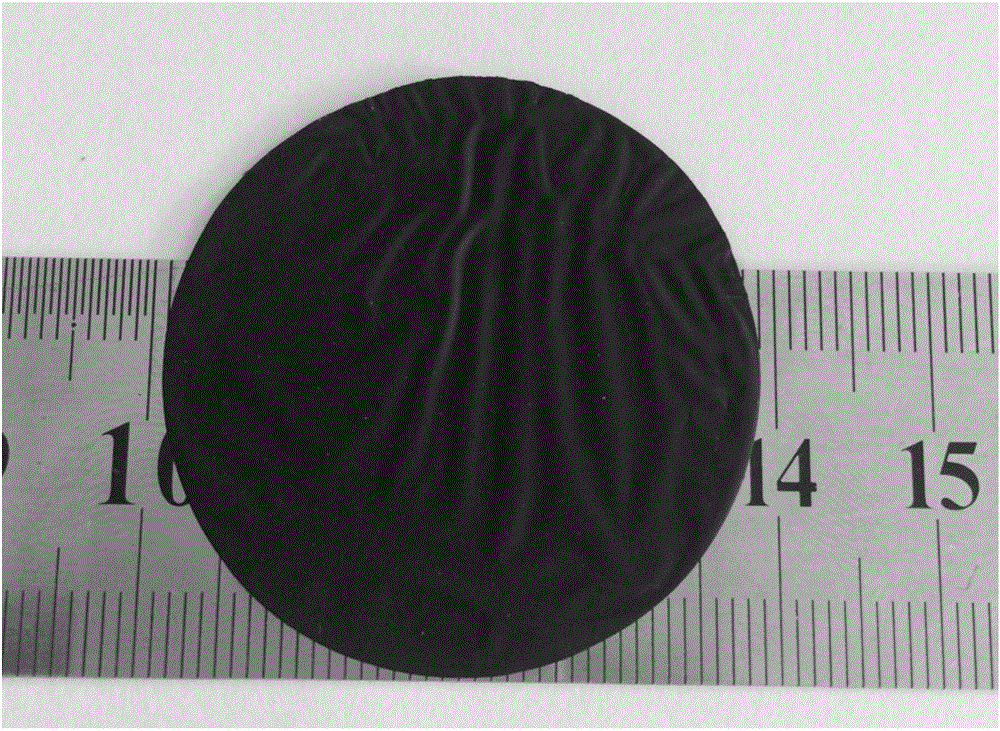

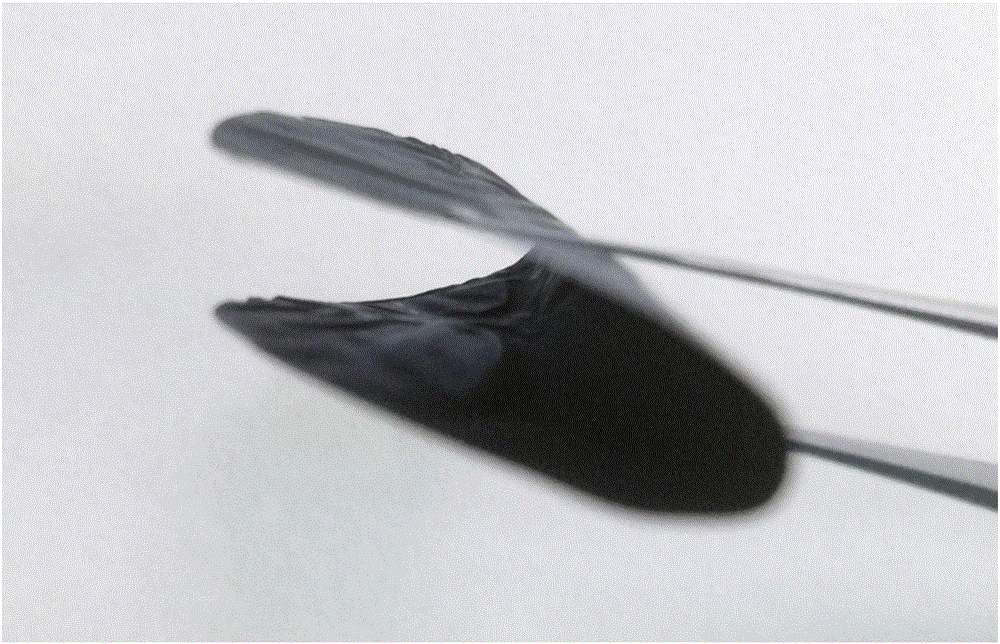

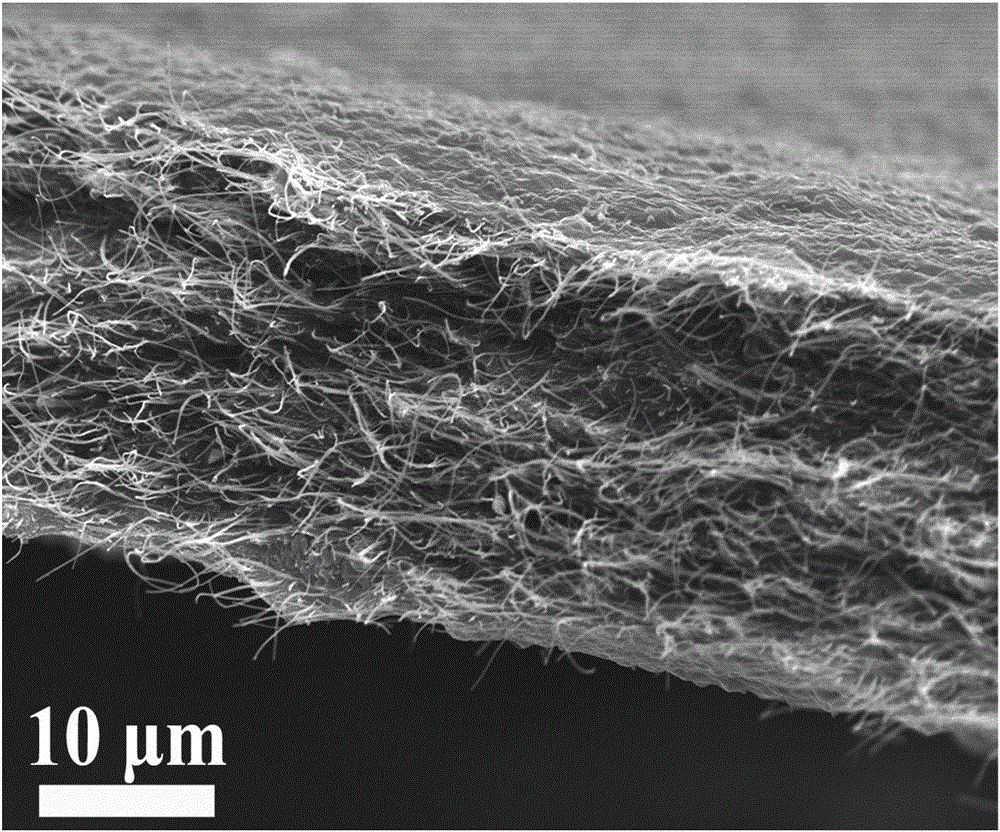

[0040] Take a carbon nanotub...

Embodiment 2

[0045] Add 0.02M potassium permanganate solution and 0.03M potassium manganate solution to 50mL of 0.25mg / mL carbon nitride aqueous phase dispersion respectively, stir at room temperature for 30 minutes, and centrifuge to wash An electroactive material composed of carbon nitride and manganese oxide is obtained. The composite of carbon nitride and manganese oxide is uniformly dispersed in water to form an electroactive material dispersion with a concentration of 1 mg / mL.

[0046] 1g of carbon nanotubes were purified in advance at 500°C for 1 hour, then 23mL of concentrated sulfuric acid was added and stirred at room temperature for 20 hours, then 350mg of sodium nitrate and 1g of potassium permanganate were added, stirred at 40°C for 2 hours and then 10mL 30% was added The oxidized modified carbon nanotubes are obtained by centrifugal washing with hydrogen peroxide water and dispersed in water.

[0047] Take a carbon nanotube aqueous solution with a concentration of 1 mg / mL, mix th...

Embodiment 3

[0049] Add 0.02M potassium permanganate solution and 0.03M potassium manganate solution to 50mL of 0.25mg / mL carbon nitride aqueous phase dispersion respectively, stir at room temperature for 30 minutes, and centrifuge to wash An electroactive material composed of carbon nitride and manganese oxide is obtained. The composite of carbon nitride and manganese oxide is uniformly dispersed in water to form an electroactive material dispersion with a concentration of 0.1 mg / mL.

[0050] 1g of carbon nanotubes were purified in advance at 500°C for 1 hour, then 23mL of concentrated sulfuric acid was added and stirred at room temperature for 20 hours, then 350mg of sodium nitrate and 1g of potassium permanganate were added, stirred at 40°C for 2 hours and then 10mL 30% was added The oxidized modified carbon nanotubes are obtained by centrifugal washing with hydrogen peroxide water and dispersed in water.

[0051] Take the carbon nanotube aqueous solution with a concentration of 0.1 mg / mL, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy density | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com