Process for preparing sodium acetate solution

A production process, sodium acetate technology, applied in the field of sodium acetate solution production process, can solve the problems of high quality, flammable and explosive sodium acetate products, and achieve simple, practical and easy-to-operate preparation method, low raw material cost and high quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

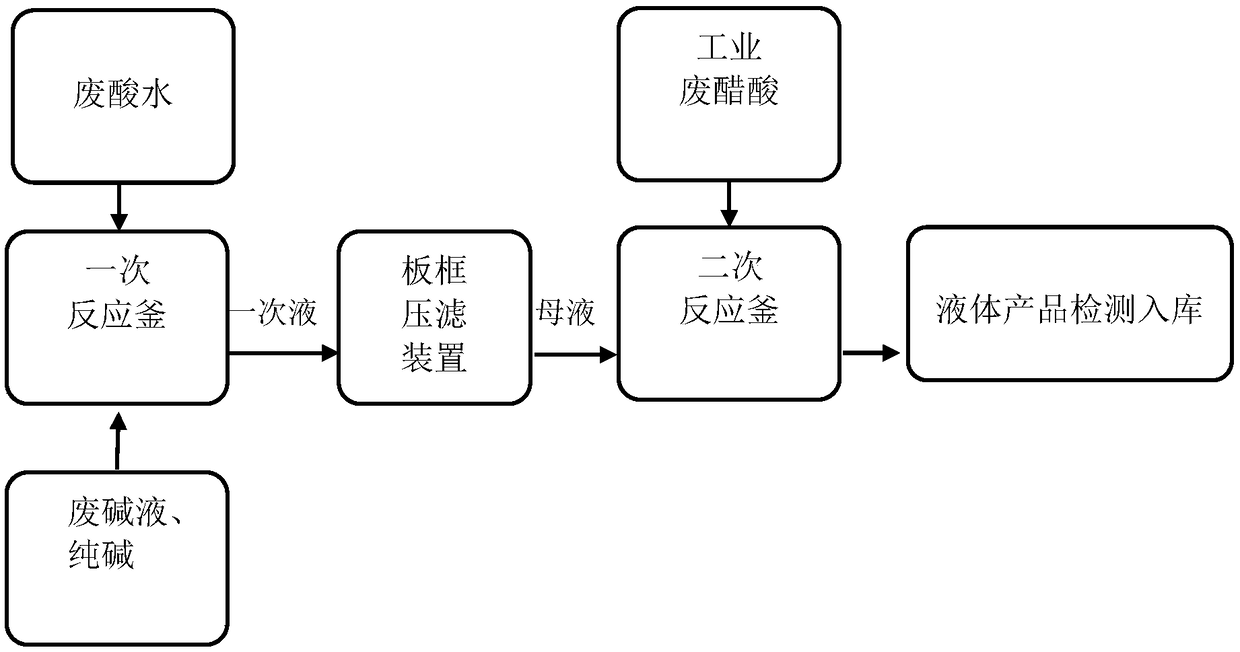

[0044] 1) Add 92 parts of waste acid water (hydrochloric acid content is 4.2%) that obtains in the technique that above-mentioned iron and steel pickling waste liquid produces ferric chloride in the primary enamel reactor that has stirring device, start stirring; Add 103 parts of spent caustic soda (sodium carbonate content is 10%) obtained in the technique of producing ferric chloride by adding above-mentioned iron and steel pickling waste liquid, stir 1h; Slowly add soda ash (sodium carbonate content is 99%) 49 when stirring part until completely dissolved evenly to obtain a primary solution, which is a soda ash solution with a sodium carbonate content of 17%, and sampling is detected;

[0045] 2) Filter the primary solution with adjusted sodium carbonate content in step 1) through a plate-and-frame filter press to obtain the mother liquor, which is sampled for detection;

[0046] 3) In the secondary enamel reaction kettle with stirring device, add 51 parts of industrial was...

Embodiment 2

[0048] 1) Add 84 parts of waste acid water (hydrochloric acid content is 4.7%) that obtains in the technique that above-mentioned iron and steel pickling waste liquid produces ferric chloride in the primary enamel reactor that has stirring device, start stirring; , add 96 parts of spent lye (sodium carbonate content is 10%) obtained in the technology that above-mentioned iron and steel pickling waste liquor produces ferric chloride, stir 1h; Slowly add soda ash (sodium carbonate content is 99%) 47 parts while stirring part until completely dissolved evenly to obtain a primary solution, which is a soda ash solution with a sodium carbonate content of 19%, and is sampled for detection;

[0049] 2) Filter the primary solution with adjusted sodium carbonate content in step 1) through a plate-and-frame filter press to obtain the mother liquor, which is sampled for detection;

[0050] 3) In the secondary enamel reaction kettle with stirring device, add 48 parts of industrial waste ac...

Embodiment 3

[0052] 1) Add 104 parts of waste acid water (the content of hydrochloric acid is 3.3%) obtained in the process of producing ferric chloride from the above-mentioned iron and steel pickling waste liquid in the primary enamel reaction kettle with stirring device, start stirring; , add 112 parts of spent caustic soda (sodium carbonate content is 10%) obtained in the technology that above-mentioned iron and steel pickling waste liquid is produced ferric chloride, stir 1h; Slowly add soda ash (sodium carbonate content is 99%) 43 parts while stirring part until completely dissolved evenly to obtain a primary solution, which is a soda ash solution with a sodium carbonate content of 18%, and sampling is detected;

[0053] 2) Filter the primary solution with adjusted sodium carbonate content in step 1) through a plate-and-frame filter press to obtain the mother liquor, which is sampled for detection;

[0054] 3) In the secondary enamel reaction kettle with stirring device, add 46 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com