Method for preparing phacellite by using coal ash as raw material

A technology of fly ash and kalephine, applied in the field of deep processing and utilization of fly ash resources, can solve the problems of easy carbon deposition, catalyst passivation, etc., and achieve the effects of low cost, good thermal stability, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1) drying the fly ash, dry gradient magnetic separation;

[0019] 2) The fly ash and potassium hydroxide after magnetic separation are mixed in a mass ratio of 1:0.1, placed in a crucible in a muffle furnace, heated to 850°C, and roasted at a constant temperature for 1 hour;

[0020] 3) Add 0.5M acid to the roasted product of fly ash at a solid-to-liquid ratio of 1:1, and dissolve in the acid for 1 hour; stir;

[0021] 4) After the acid dissolution is finished, the filter residue is filtered, washed and dried to obtain the fly ash pretreatment sample;

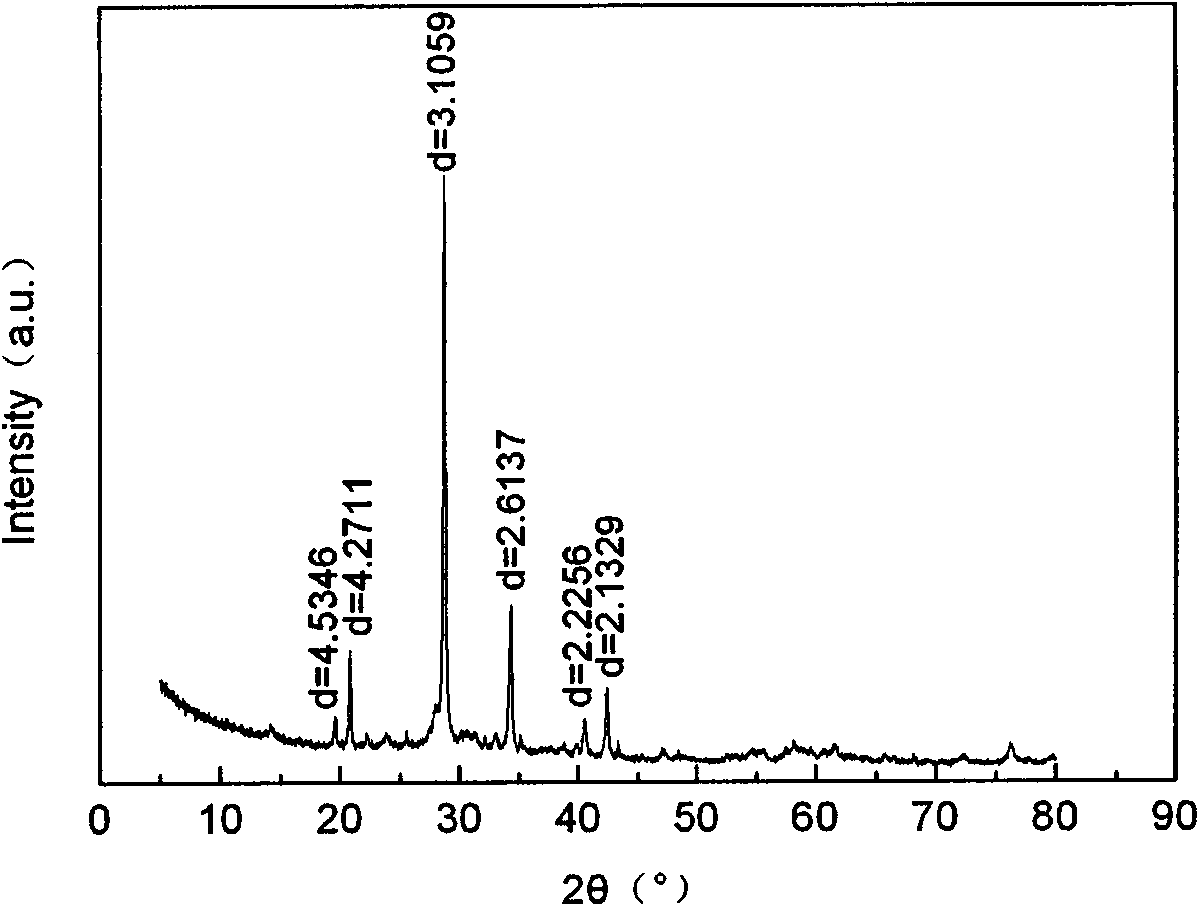

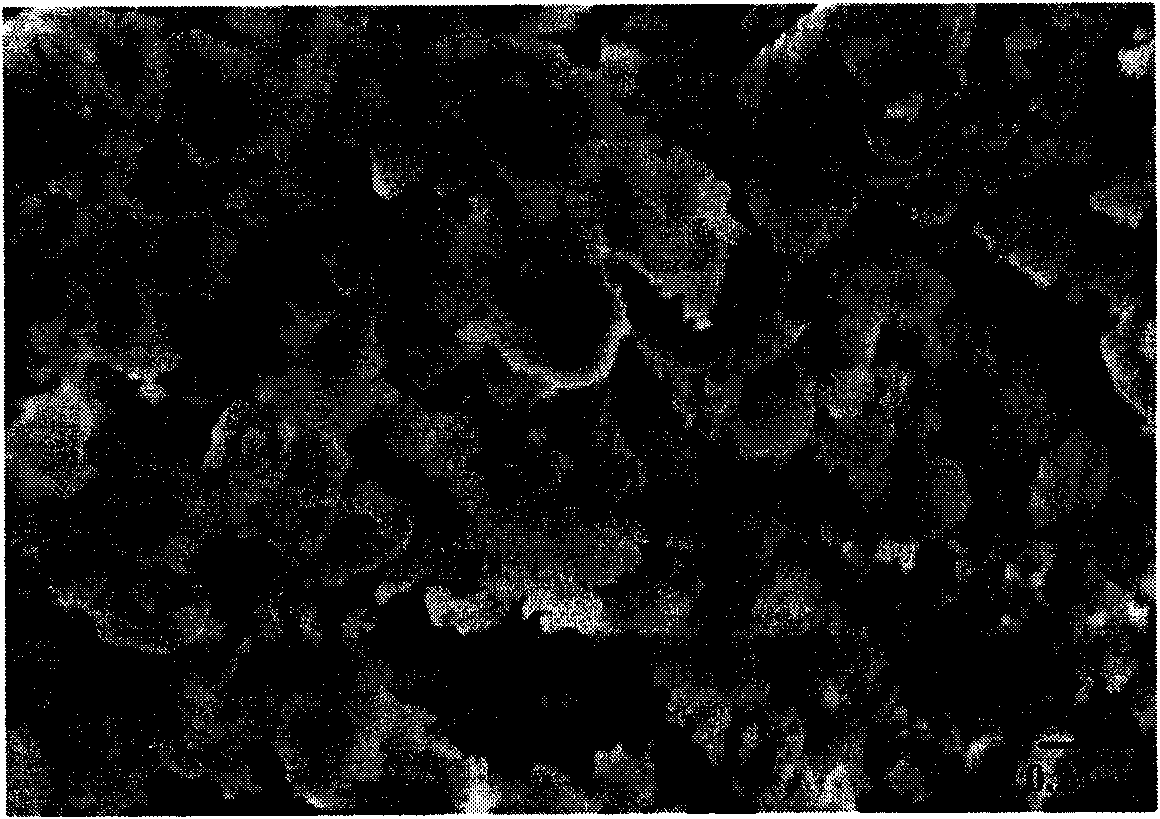

[0022] 5) Weigh the fly ash pretreatment sample, add 1M potassium hydroxide solution according to the solid-to-liquid ratio of 1:2, place the reaction mixture in a stainless steel reactor, heat to 120°C, hydrothermally react for 8 hours, filter and wash , dried to obtain kalephine, its XRD pattern is shown in figure 1 , SEM image see figure 2 .

Embodiment 2

[0024] 1) drying the fly ash, dry gradient magnetic separation;

[0025] 2) The fly ash and potassium hydroxide after magnetic separation are mixed in a mass ratio of 1:0.3, placed in the crucible of a muffle furnace, heated to 1000°C, and roasted at a constant temperature for 2 hours;

[0026] 3) Add 1.5M acid to the fly ash roasted product at a solid-to-liquid ratio of 1:2, and dissolve in the acid for 2 hours; during the acid-dissolving process, add 0.5M sodium oxalate at a solid-to-liquid ratio of 1:0.5 and keep stirring;

[0027] 4) After the acid dissolution is finished, the filter residue is filtered, washed and dried to obtain the fly ash pretreatment sample;

[0028] 5) Weigh the fly ash pretreatment sample, add 3M potassium hydroxide solution according to the solid-to-liquid ratio of 1:2, place the reaction mixture in a stainless steel reactor, heat to 180°C, hydrothermally react for 12 hours, filter and wash , drying to obtain kalpheline.

Embodiment 3

[0030] 1) drying the fly ash, dry gradient magnetic separation;

[0031] 2) The fly ash and potassium hydroxide after magnetic separation are mixed in a mass ratio of 1:0.2, placed in a crucible in a muffle furnace, heated to 900°C, and roasted at a constant temperature for 1.5 hours;

[0032] 3) Add 1M acid to the fly ash roasted product at a solid-to-liquid ratio of 1:3, and dissolve in the acid for 1.5 hours; during the acid-dissolving process, add 0.3M sodium citrate at a solid-to-liquid ratio of 1:0.2 and keep stirring;

[0033] 4) After the acid dissolution is finished, the filter residue is filtered, washed and dried to obtain the fly ash pretreatment sample;

[0034] 5) Weigh the fly ash pretreatment sample, add 2M potassium hydroxide solution according to the solid-to-liquid ratio of 1:2, place the reaction mixture in a stainless steel reactor, heat to 160°C, hydrothermally react for 10 hours, filter and wash , drying to obtain kalpheline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com